Method utilizing ultraviolet oxidation in implementing and regulating graphene film patterning

A technology of graphene film and ultraviolet light, which is applied in the direction of electrical components, nanotechnology, electric solid devices, etc., can solve the problems of high distortion of graph structure and damage of graphene surface near the edge, so as to achieve convenient cost, improve quality, The effect of high graphics precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

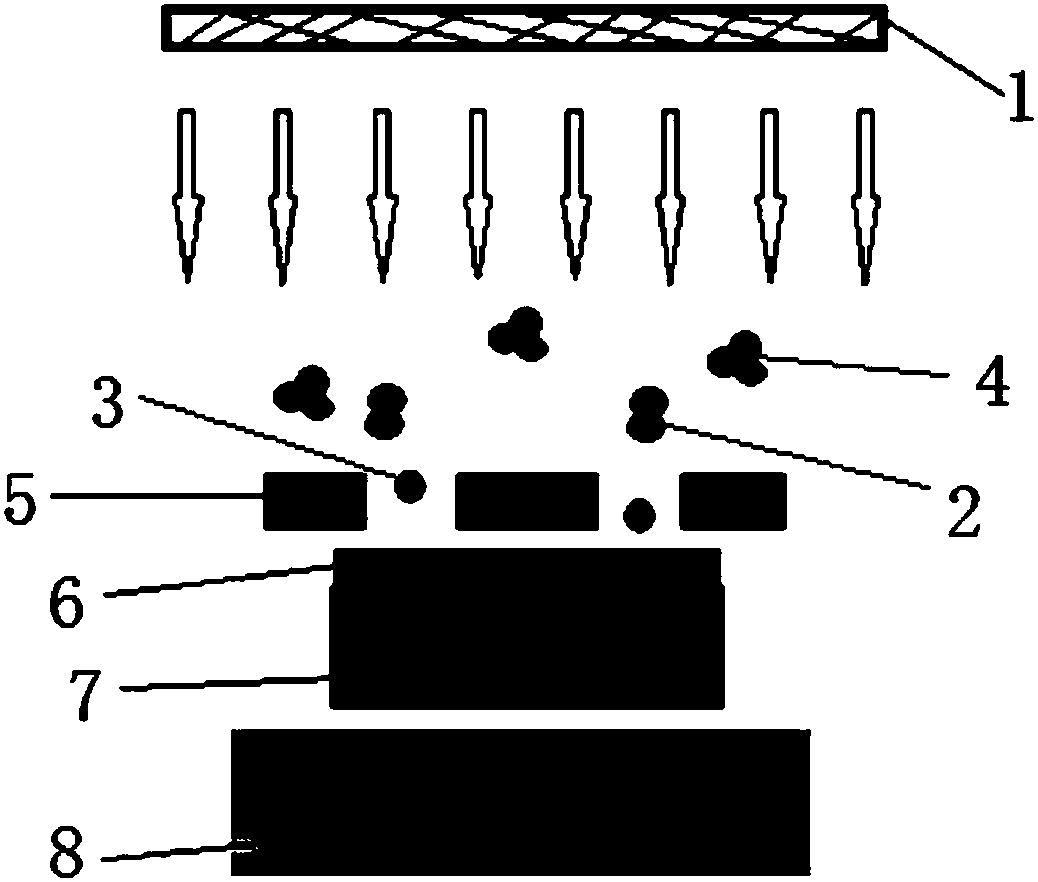

[0049] The method for realizing and regulating the patterning of graphene film by ultraviolet photooxidation comprises the following steps:

[0050] Step 1, place a hard mask plate with a certain pattern structure such as a ferromagnetic stainless steel plate (thickness 50 μm) closely on the SiO2 film transferred with a graphene film 2 / Si substrate.

[0051] Step 2, place the graphene film and the hard mask plate in step 1 together in the ultraviolet light oxidation equipment with the xenon lamp excimer discharge tube as the light source, adjust the distance between the sample and the lower surface of the xenon lamp excimer discharge tube to be 20mm, oxygen The pressure is 10 Pa, the vacuum chamber is filled with nitrogen and the pressure is 1 atm, and the xenon lamp excimer light source is irradiated for 15 minutes.

[0052] Step 3, place the graphene film and the hard mask plate in step 1 at either end of the S-N pole of the NdFeB permanent magnet whose surface magnetic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com