Patterned flexible organic film and manufacturing method thereof, stacked body and patterning method

An organic thin film and patterning technology is applied in the field of patterning laminates, patterned modification of organic substrate thin films, and flexible organic thin films, which can solve the problems of poor etching uniformity and precision, and achieve good application prospects The effect of eliminating stress unevenness and uniform pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0058] The first embodiment of the present invention provides a patterned flexible organic film obtained by patterning a functional film in contact with the flexible organic film to be patterned, wherein: The functional film contains a solution capable of reacting with the flexible organic film to be patterned; the functional film is obtained through a dry papermaking method and contains fibers.

[0059] flexible organic film

[0060] The flexible organic film used in the present invention is not particularly limited, as long as it is a commonly used patterned base film, which can be modified by chemical reaction with a solution and finally form a desired pattern. Such a reaction can be that the flexible organic film undergoes polymerization, curing, crosslinking and other reactions when in contact with the solution, or it can be the depolymerization, degradation or structural destruction of the flexible organic film when in contact with the solution.

[0061] Without limit...

no. 2 approach

[0093] The second embodiment of the present invention provides a flexible organic thin film patterning method, which includes the following steps: a) the step of preparing a flexible organic thin film to be patterned and a functional film; b) combining the functional film and the functional film to be patterned The step of contacting the flexible organic film, the functional film contains a solution capable of reacting with the flexible organic film to be patterned, and the functional film is obtained by a dry papermaking method and contains fibers.

[0094] The flexible organic thin film, functional film, and solution according to the second embodiment may be the same as those described in the aforementioned .

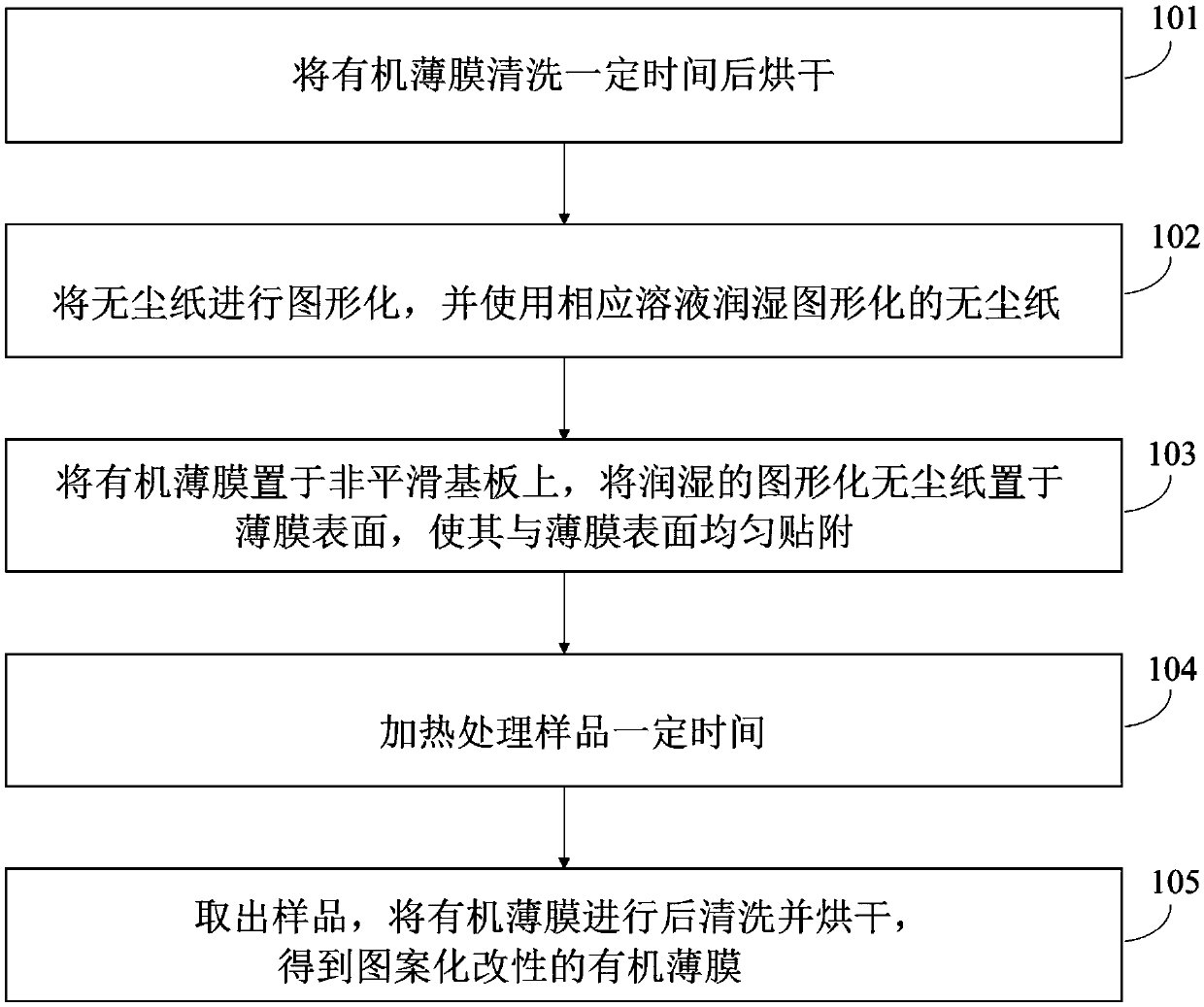

[0095] see figure 1 , the present invention will describe the patterning method of the flexible organic thin film in further detail. In order to reduce the complexity of the process, realize the patterned modification of polysulfide films, improve the patterning acc...

no. 3 approach

[0119] The third embodiment of the present invention provides a laminated body for patterning, the laminated body comprising: a base layer; a functional film layer, the functional film layer is disposed on at least one surface of the base layer; and optionally A peelable layer, the peelable layer is disposed on the surface of the functional film layer opposite to the base layer, wherein the functional film layer includes a fiber-containing film obtained by a dry-laid papermaking method.

[0120] The base layer may be formed of any suitable resin. Examples of the resin used to form the base layer include polyester-based resins such as polyethylene terephthalate and polybutylene terephthalate, polyolefin-based resins such as low-density polyethylene, linear poly Ethylene, random copolymer polypropylene, homopolypropylene and ethylene-propylene copolymer, ethylene-vinyl acetate copolymer, ionomer resin, polyurethane-based resin, polyvinylidene chloride, polyvinyl chloride, polyam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com