Three-dimensional ceramic substrate comprising cavity structure and fabrication method of three-dimensional ceramic substrate

A technology of ceramic substrate and cavity, which is applied in the field of three-dimensional ceramic substrate with cavity structure and its preparation, can solve the problems of difficult packaging materials and process compatibility, limited mass production and application, high cost, etc., and achieves good fluidity, material Low cost and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

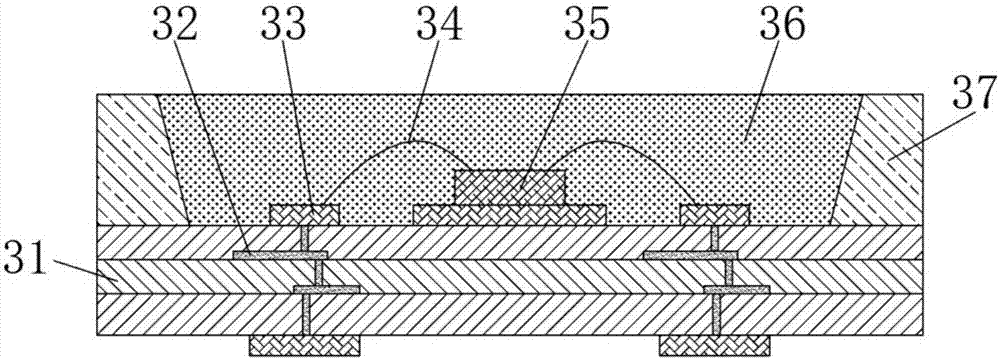

[0046] A method for preparing a three-dimensional ceramic substrate with a cavity structure according to an embodiment of the present invention specifically includes:

[0047] (1) preparing a planar ceramic substrate containing metal circuits;

[0048] (2) Design and prepare a mold according to the cavity structure and size requirements, and the mold material is plastic, rubber or other polymer materials;

[0049] (3) cleaning the planar ceramic substrate and the mould, and aligning the planar ceramic substrate with the mould;

[0050] (4) Prepare low-temperature curing ceramic slurry. Low-temperature curing ceramic slurry is a kind of inorganic material slurry, which is composed of water, oxide and phosphate materials in proportion. High strength (compressive strength greater than 30MPa), good heat resistance, corrosion resistance and other advantages. In particular, the ceramic slurry can be cured at room temperature or below 100 degrees to meet the requirements of direct...

Embodiment 1

[0055] Fig. 6(a) is a schematic structural diagram of a three-dimensional ceramic substrate with a cavity structure according to an embodiment of the present invention, Figure 10 It is a schematic diagram of a three-dimensional ceramic substrate with a cavity structure according to an embodiment of the present invention, as shown in Figure 6(a) and Figure 10 As shown, Embodiment 1 provides a three-dimensional ceramic substrate with a cavity structure, including an electroplated ceramic substrate 60 and a cavity structure 61 . Wherein, the electroplated ceramic substrate includes a ceramic substrate 62, a metal circuit 63 and a metal through hole 64; the cavity is located on the ceramic substrate 62 and the metal circuit 63, and is an annular structure, and the inner diameter of the annular cavity is 2mm. The outer diameter is 3mm and the height is 0.3mm.

[0056] A method for preparing a three-dimensional ceramic substrate with a cavity structure in Example 1, comprising: ...

Embodiment 2

[0065] As shown in FIG. 12( a ), Embodiment 2 provides a three-dimensional ceramic substrate with a cavity structure, including a planar ceramic substrate and a cavity structure 123 . Wherein, the planar ceramic substrate is a thick film ceramic substrate (TFC), including a ceramic substrate 121 and a metal circuit 122; the cavity is located on the ceramic substrate 121 and the metal circuit 122, and is a square ring structure with a side length of 5mm. The ring width is 1mm and the height is 1.0mm.

[0066] A method for preparing a three-dimensional ceramic substrate with a cavity structure according to embodiment 2, comprising:

[0067] (1) Prepare a thick film ceramic substrate (TFC) with metal circuits on the surface;

[0068] (2) According to the cavity structure requirements, process the metal mold (die), and then obtain the polytetrafluoroethylene mold by the mold transfer method;

[0069] (3) Use ethanol and deionized water to clean the thick-film ceramic substrate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com