Method of manufacturing gravure plates for offset printing

A printing plate and gravure technology, applied in the field of preparing gravure printing plates for offset printing, to achieve the effects of high graphic accuracy, excellent thickness uniformity and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

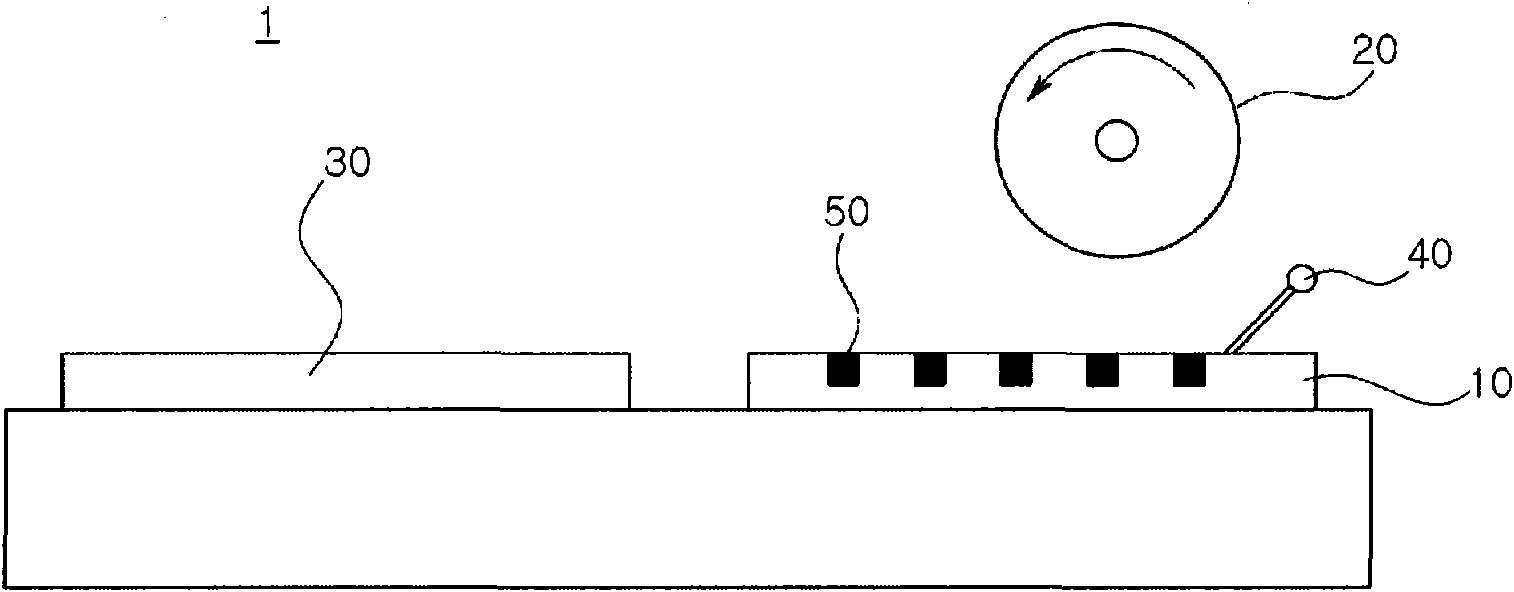

[0019] A method for preparing a gravure printing plate for offset printing according to an exemplary embodiment of the present invention is characterized in that the method includes the steps of: coating a glass substrate with copper metal; forming a photoresist film on the coated copper metal; The desired photoresist pattern is formed by exposing the photoresist film to light and then developing the photoresist film to remove the photoresist from some of the photoresist film; plating nickel to the areas where the photoresist was removed; and removing the remaining photoresist and polish the nickel-plated surface.

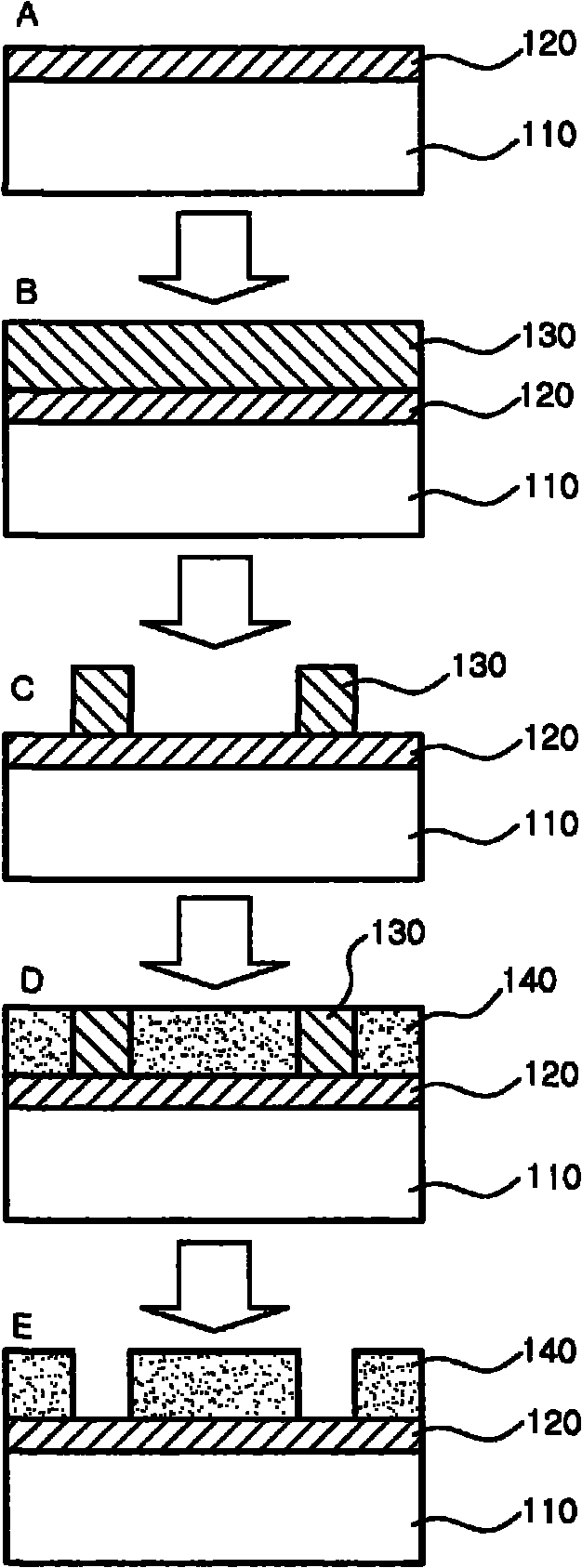

[0020] figure 2 is a diagram showing a method of preparing a gravure printing plate for offset printing according to an exemplary embodiment of the present invention. In the following, refer to figure 2 Each step of the method is described in more detail.

[0021] (1) Operation of coating copper metal (A)

[0022] First, a glass substrate is coated with coppe...

Embodiment

[0045] Copper metal was sputtered onto a glass substrate (ie, soda lime glass, available from KCC) at a pressure of 3 mTorr and a power of 5 kW, thereby forming a copper coating film with a thickness of 200 nm.

[0046] A negative type dry film resist (DFR, available from KOLON) was adhered to the copper coating film, and then irradiated for 2 to 10 seconds through a photomask using i-line ultraviolet rays with a wavelength of 365 nm . Next, add 1% Na 2 CO 3 The aqueous solution (developing solution) is sprayed onto the film type photoresist, and the dry film resist is developed for 1 to 3 minutes to form a photoresist pattern.

[0047] Next, pickle the substrate with 5% sulfuric acid in PdCl 2 The substrate was immersed in an aqueous solution for 2 minutes to introduce a Pd catalyst onto the copper surface, and it was immersed in an electroless plating solution of Ni for 90 minutes to plate nickel on the substrate. In this case, the nickel plating solution was prepared by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com