Exposure development method for circuit board

A technology of exposure and development, circuit board, applied in the directions of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of poor pattern uniformity and poor pattern accuracy, and achieve the effect of avoiding exposure and improving pattern accuracy and pattern uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

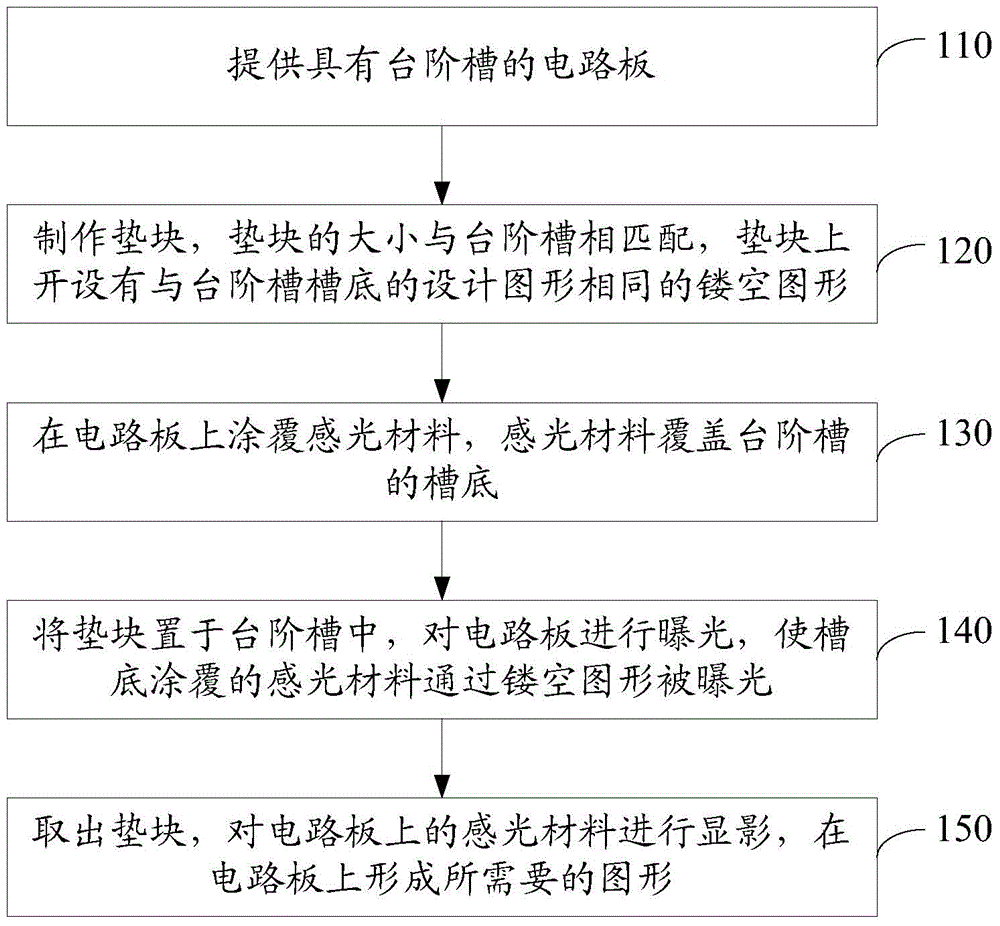

[0023] Please refer to figure 1 , an embodiment of the present invention provides a method for exposing and developing a circuit board, which may include:

[0024] 110. Provide a circuit board with stepped grooves.

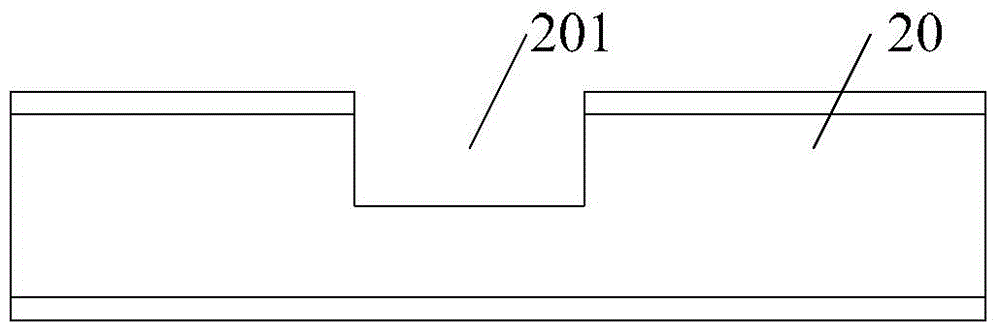

[0025] like figure 2 Shown is a schematic diagram of the circuit board 20 in the embodiment of the present invention. The circuit board 20 has a stepped groove 201. The groove bottom of the stepped groove 201 can be processed or not processed according to actual needs. The circuit board 20 can be produced by conventional processing methods, such as blanking, inner layer graphics, lamination, drilling, slotting, outer layer graphics and other steps.

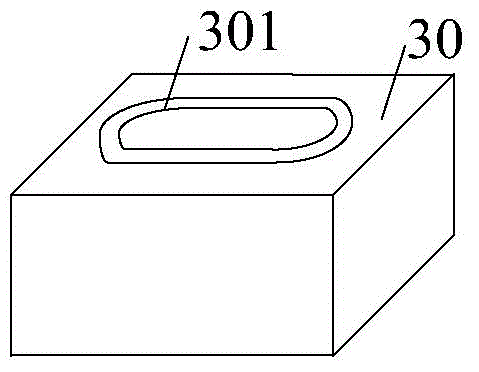

[0026] 120. Make a spacer, the size of which matches the step groove, and the spacer is provided with the same hollow figure as the design figure at the bottom of the step groove.

[0027] like image 3 As shown, it is a schematic diagram of the spacer 30 made in the embodiment of the present invention. The size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com