Uniform temperature distribution method and curing device for microwave-pressure curing composite material

A composite material, uniform distribution technology, applied in the field of composite material curing and forming, can solve the problems of poor uniformity, high energy consumption, low heating efficiency, etc., and achieve the effect of eliminating heating unevenness, improving temperature uniformity, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

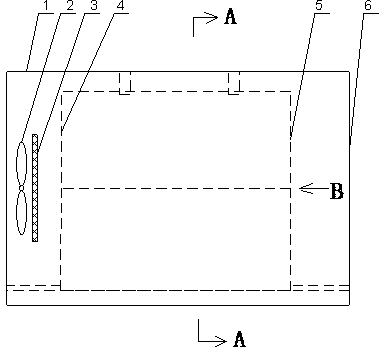

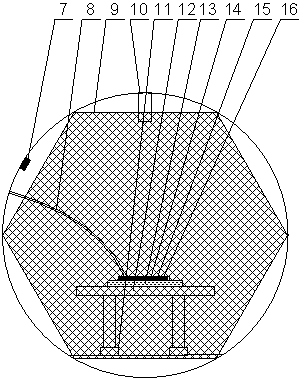

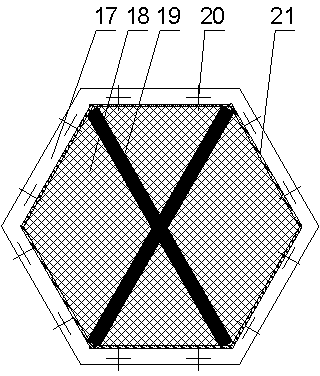

[0027] Such as Figure 1-3 shown.

[0028] A method for uniform temperature distribution of microwave-pressure-cured composite materials. Firstly, a composite material component 14 is placed in a polygonal cavity 9, so that microwave energy is incident on the surface and interior of the composite material 14 after multiple reflections in the polygonal cavity 9 ; At the same time, the gas pressure is provided by the pressure vessel to act on the surface of the composite material to compact the material; when the measured temperature of the composite material 14 shows a temperature difference (generally 5°C-10°C), heat or cool the gas in the pressure vessel 1 Medium, and the gas medium is circulated through the electromagnetic shielding ventilation window provided on the polygonal cavity 9, and convective heat exchange occurs with the composite material, so as to improve the temperature uniformity of the composite material member 14.

Embodiment 2

[0030] A microwave-pressure composite curing device with uniform temperature distribution, which includes a pressure vessel 1, a curing chamber 9 installed in the pressure vessel 1, a vacuum generating device and a microwave generating device, such as figure 1 As shown, the vacuum generating device passes through the pressure vessel 1 and the curing chamber 9 through the vacuum tube 8 and communicates with the vacuum bag 15 of the rotary curing workpiece 14, and the microwave generated by the microwave generating device is sent into the curing chamber 9 through the microwave transmission line 7, and the vacuum The bag 15 is installed on the mold 13, the mold 13 is installed on the stage 12, the stage 12 is installed on the guide rail 11, and the guide rail 11 is installed in the curing cavity 9, and the inner cavity cross section of the curing cavity 9 is Polygonal structures that can reflect microwaves multiple times, among which the hexagonal shape is the best, can also be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com