Substrate for flexible photoelectronic device and preparation method thereof

A technology of optoelectronic devices and substrates, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, and photovoltaic power generation, and can solve problems such as poor bonding force between silver nanowire films and flexible substrates, and large roughness of silver nanowire films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

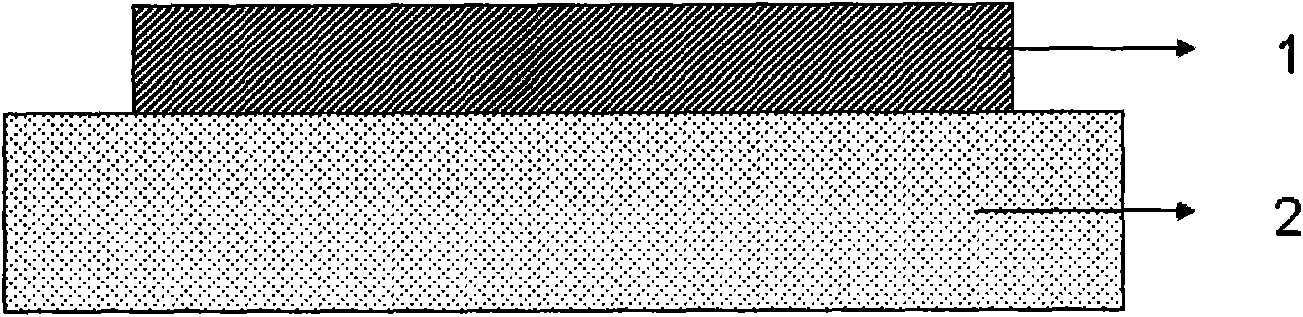

[0094] Such as figure 1 In the shown substrate structure, the flexible substrate 1 uses an adhesive that needs to be double-cured, and the conductive layer 2 uses a silver nanowire film, and the gaps of the silver nanowire film are filled with graphene.

[0095] The preparation method is as follows:

[0096] ① Clean the glass substrate with surface roughness less than 1nm, and dry it with dry nitrogen after cleaning;

[0097] ② Disperse the silver nanowires evenly in the solvent, and prepare the silver nanowire thin film on the clean substrate by spin coating. The rotation speed of the spin coating is 4000 rpm, the duration is 60 seconds, and the film thickness is about 70 nanometers;

[0098] ③ Drop-coat the graphene-containing solution on the silver nanowire film, place the glass substrate in an environment of 80°C for 30 minutes, remove the remaining solvent in the silver nanowire film, and then spray the double-cured adhesive on the silver nanowire film , the adhesive ra...

Embodiment 2

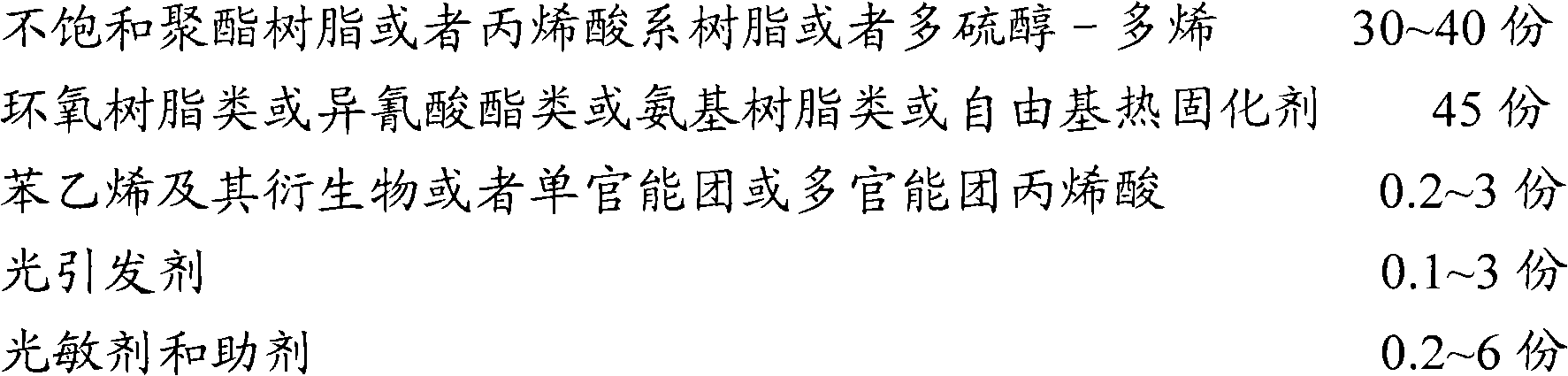

[0106] Such as figure 1 In the shown substrate structure, the flexible substrate 1 adopts an adhesive that requires double curing, the conductive layer 2 adopts a silver nanowire film, and the gaps of the silver nanowire film are filled with graphene, and the raw material of the adhesive includes the following components:

[0107]

[0108] The preparation method is similar to Example 1.

Embodiment 3

[0110] Such as figure 1 In the shown substrate structure, the flexible substrate 1 adopts an adhesive that requires double curing, the conductive layer 2 adopts a silver nanowire film, and the gaps of the silver nanowire film are filled with graphene, and the raw material of the adhesive includes the following components:

[0111]

[0112] The preparation method is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com