Method and device for curing fiber-reinforced resin-based composite material component by utilizing microwaves

A composite material component and fiber-reinforced resin technology, which is applied in the field of microwave-cured fiber-reinforced resin-based composite material components, and uses microwaves for final curing of composite material components, can solve the problems of large energy consumption and long cycle, and achieve uniform heating, Small internal stress and deformation, and the effect of improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like Figure 1-4 shown.

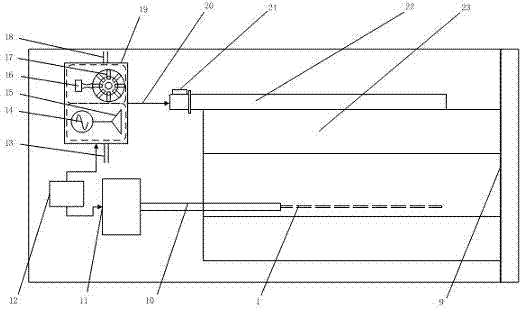

[0034] A method for microwave curing of fiber-reinforced resin-based composite components, which first pre-evacuates one or several layers of prepreg fiber layups used to manufacture composite components, and puts them into octagonal multi-mode Microwave heating is carried out in the resonant cavity. During the entire curing process, temperature sensors are used to monitor the temperature of multiple points on the surface of the component, and the microwave power is automatically controlled to make the heating temperature conform to the process curve. Real-time measurement and monitoring of temperature and vacuum of components during curing. After the composite material is solidified, the furnace door is opened, and the component is placed outside the device to cool down. The next batch of parts and components are then put into the device for solidification and molding according to the above method. like figure 1 , 2 shown.

[0035] Duri...

Embodiment 2

[0037] like Figure 1-3 shown.

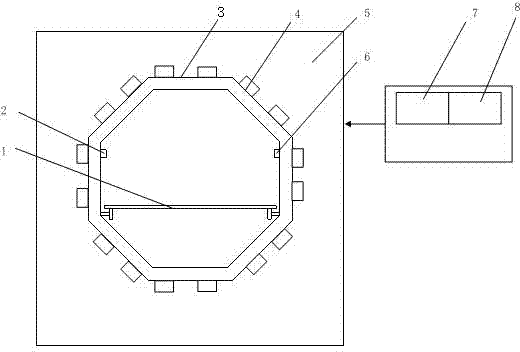

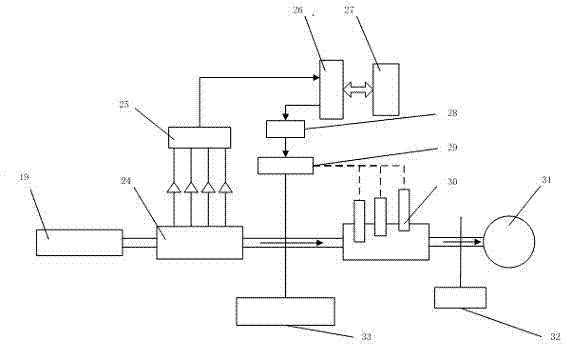

[0038] A device for microwave-curing fiber-reinforced resin-based composite components, which includes: a carrier glass plate 1, a vacuum tube interface 2, a choke groove 3, a slit antenna 4, a furnace body 5, a temperature sensor joint 6, a temperature control panel 7, Operation panel 8, such as figure 1 , furnace door 9, ball screw 10, stepper motor 11, PLC12, cooling water inlet 13, cooling water outlet 18, microwave source 19, microwave transmission line 20, impedance matching device 21, rectangular waveguide device 22 and octagonal multi mode resonator 23, such as figure 2 , the octagonal multimode resonant cavity 23 is installed in the furnace body 5, the rear portion of the octagonal multimode resonant cavity 23 has a movement channel for the ball screw 10, the rest of the rear part is sealed, and the front furnace door 9. A common choke-sealed metal coil is used to ensure no electromagnetic leakage; the loading glass plate 1 is conn...

specific Embodiment

[0039] Taking carbon fiber as a reinforcing material and taking a thermosetting resin as a matrix, the specific embodiments of curing the components of the present invention are as follows:

[0040] Figure 4 It is the layering process of the composite material of the present invention on the mould. Brush a layer of release agent 102 evenly on the molding surface of the mold 101, brush the second time after 20 minutes, and brush the third time after another 30 minutes. After the release agent 102 is dried and solidified, take 20 layers of the prepreg 106 of the thermosetting resin-based carbon fiber reinforced composite material that has been cut, and lay them on the mold made of the composite material in the order of 0°, 45°, 90°, and 135°. 101, make the layer and layer, between the material surface and the mould, be close to each other.

[0041] After the layering is completed, a release cloth 103, a porous isolation film 105, an air felt 107, and a vacuum bag 104 are sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com