Prediction method for composite microwave curing temperature field

A composite material, microwave curing technology, used in the temperature field prediction of microwave cured composite materials, and the field of microwave curing of composite materials, it can solve the problems of lack of microwave prediction cost, accuracy can not meet the requirements of use, etc., to save cost, shorten cycle, predict high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

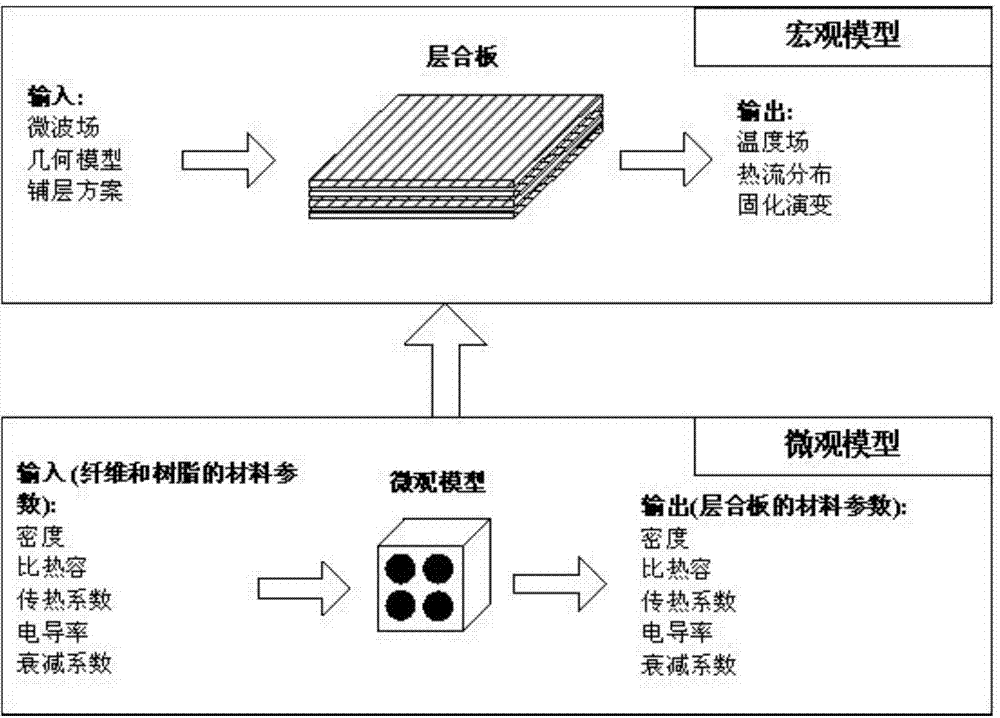

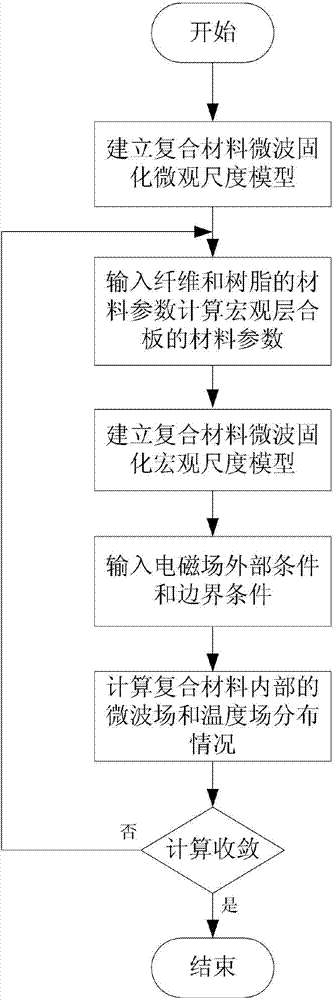

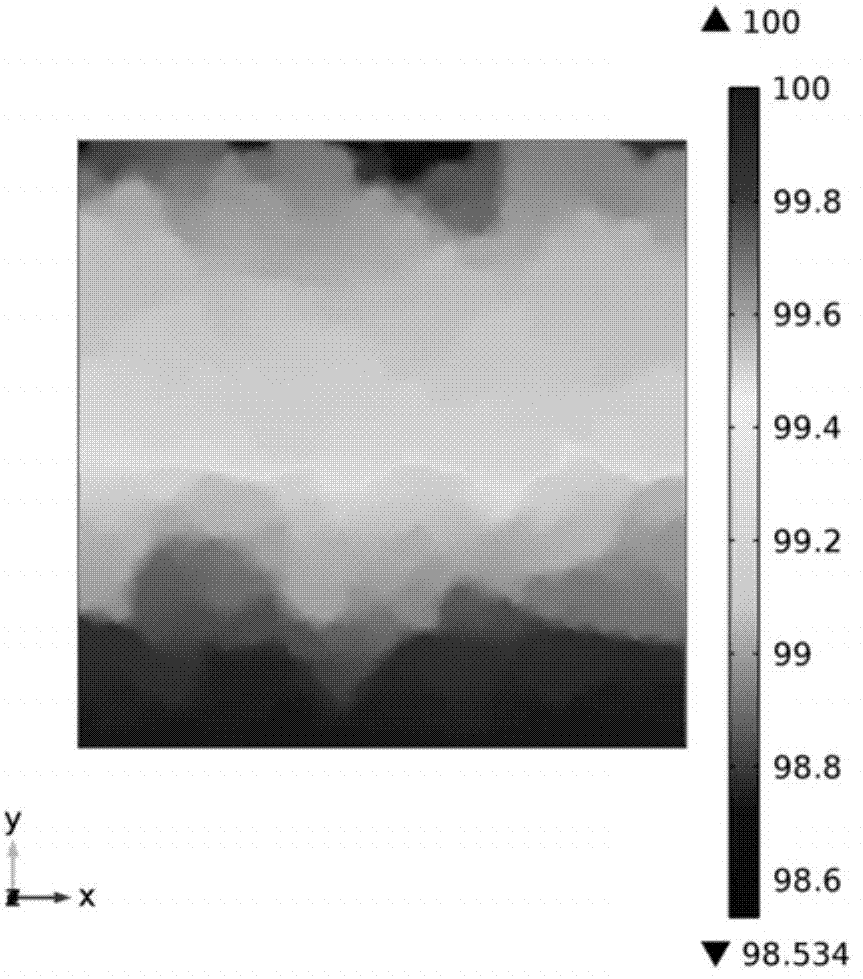

[0017] A method for predicting the microwave curing temperature field of composite materials. Firstly, establish a microscale model of reinforcement and resin matrix, then calculate the electromagnetic parameters and microwave attenuation model of the microscale model, and then transfer the parameters and attenuation model to the macroscale model , and finally, the microwave field and temperature field distributions of composite materials are calculated and predicted by macro-scale models. The microscopic model is a multi-dimensional model taken from a real composite material section, including a reinforcement and a resin matrix, with a scale ranging from 1 to 2900 microns. The input condition of the microscopic scale model is the physical and electromagnetic parameters of the microscopic material, and the output is the overall microscopic The physical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com