Method of solidifying composite material with wave-absorbing material mould through microwave heating

A wave-absorbing material and composite material technology, which is applied in the field of composite material manufacturing, can solve the problem that carbon fiber cannot be cured by microwaves, and achieve the effect of reducing time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

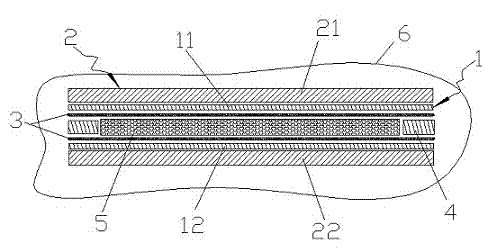

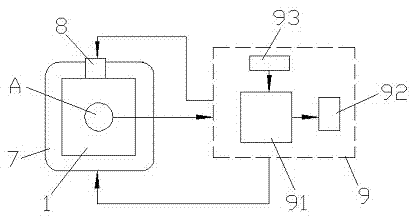

[0025] figure 1 and figure 2 It is a schematic diagram of the process principle of the present invention.

[0026] The reference signs therein are: optical fiber temperature sensor A, wave-absorbing material mold 1, upper wave-absorbing material mold 11, lower wave-absorbing material mold 12, hard mold 2, upper hard mold 21, lower hard mold 22, polymer PTFE film 3, limit frame 4, composite material 5, vacuum bag 6, microwave equipment 7, vacuum device 8, control system 9, main control module 91, display module 92, setting module 93.

[0027] Such as Figure 1 to Figure 2 As shown, a method of using microwaves to heat a wave-absorbing material mold to solidify a composite material in the present invention, the method is to place the wave-absorbing material mold 1 in a microwave field, and utilize the characteristics of microwave rapid and un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com