Microwave curing formation method for carbon fiber/epoxy resin composite materials and laminated plate made of composite materials

An epoxy resin layer and epoxy resin technology, which is applied in the field of carbon fiber/epoxy resin composite laminates and vacuum bag pressure microwave curing forming, can solve the problems of no composite material system, no mention of process parameters, etc., and achieve curing. The effect of shortened process cycle, avoidance of curing pressure loss, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

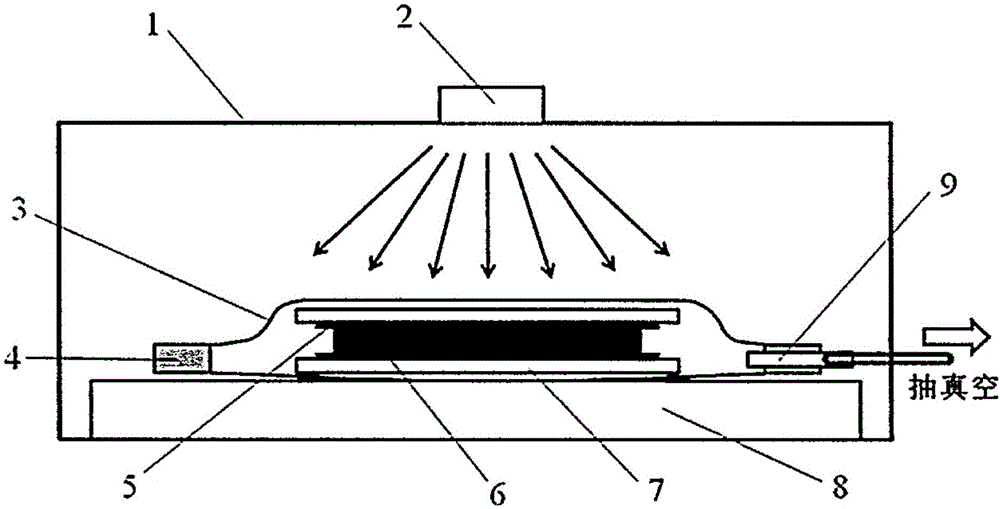

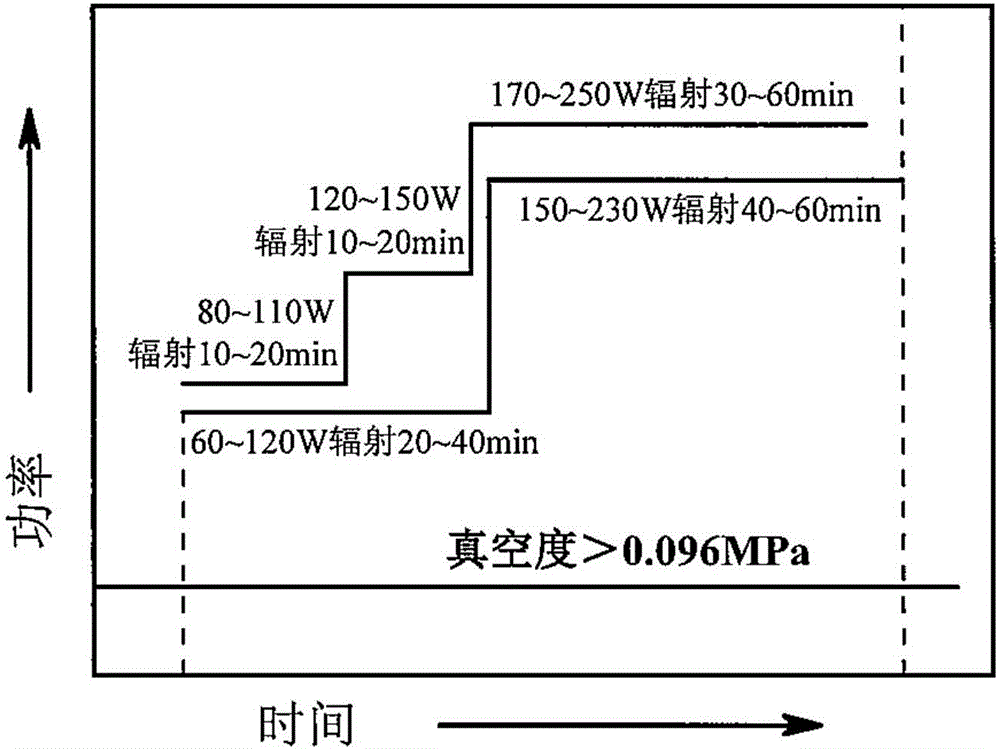

[0024] refer to figure 1 and figure 2 , so that the carbon fibers are arranged along the length direction, and the T800 carbon fiber / epoxy resin prepreg is laid up into 12 layers of 18cm (length) × 8cm (width) unidirectional carbon fiber / epoxy resin prepreg laminates 6; A good carbon fiber / epoxy resin prepreg laminate 6 is pasted with an isolation film 5 made of polyimide on the upper and lower sides, placed between two flat molds 7 made of quartz glass plates, and then placed in a polyimide In a vacuum bag 3 made of imide film, the vacuum bag 3 is completely sealed with a vacuum bag sealing tape 4 and placed on a heat insulation board 8 . In a microwave device with a frequency of 2.45 GHz, the vacuum bag 3 is first vacuumed for 40 minutes, so that the carbon fiber / epoxy resin prepreg laminate 6 in the vacuum bag 3 is compacted at about one atmospheric pressure; Tube 9 carries out vacuuming operation, and while vacuumizing, start microwave equipment (as an example, microwav...

Embodiment 2

[0026] refer to figure 1 and figure 2 , so that the carbon fibers are arranged along the length direction, and the T800 carbon fiber / epoxy resin prepreg is laid up into 14 layers of 20cm (length) × 8cm (width) unidirectional carbon fiber / epoxy resin prepreg laminates 6; A good carbon fiber / epoxy resin prepreg laminate 6 is pasted with an isolation film 5 made of polyimide on the upper and lower sides, placed between two flat molds 7 made of quartz glass plates, and then placed in a polyimide In a vacuum bag 3 made of imide film, the vacuum bag 3 is completely sealed with a vacuum bag sealing tape 4 and placed on a heat insulation board 8 . In a microwave device with a frequency of 2.45GHz, first vacuumize the vacuum bag 3 for 50 minutes, so that the carbon fiber / epoxy resin prepreg laminate 6 in the vacuum bag 3 is compacted at about one atmospheric pressure; Tube 9 carries out vacuuming operation, and while vacuumizing, start microwave equipment (as an example, microwave e...

Embodiment 3

[0028] refer to figure 1 and figure 2 , so that the carbon fibers are arranged along the length direction, and the T700 carbon fiber / epoxy resin prepreg is laid up into 18 layers of 18cm (length) × 10cm (width) unidirectional carbon fiber / epoxy resin prepreg laminates 6; A good carbon fiber / epoxy resin prepreg laminate 6 is pasted with an isolation film 5 made of polyimide on the upper and lower sides, placed between two flat molds 7 made of polytetrafluoroethylene flat plates, and then placed in a The vacuum bag 3 made of polyimide film is completely sealed with a vacuum bag sealing tape 4 and placed on a heat insulation board 8 . In a microwave device with a frequency of 2.45GHz, first vacuumize the vacuum bag 3 for 50 minutes, so that the carbon fiber / epoxy resin prepreg laminate 6 in the vacuum bag 3 is compacted at about one atmospheric pressure; Tube 9 carries out vacuuming operation, and while vacuumizing, start microwave equipment (as an example, microwave equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com