Microwave solidification type bonding agent and microwave solidification method thereof

A microwave curing and adhesive technology, applied in chemical instruments and methods, surface pretreatment bonding methods, adhesives, etc., can solve the problems of shortening curing reaction time, uneven curing, large temperature gradient of the adhesive layer, etc., to achieve Save curing time, simple operation and easy implementation, and reduce the effect of the temperature gradient of the adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

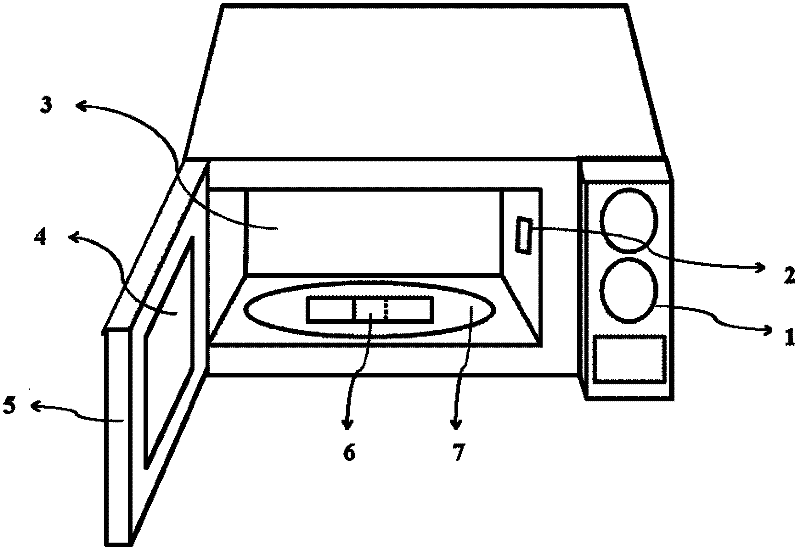

[0016] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

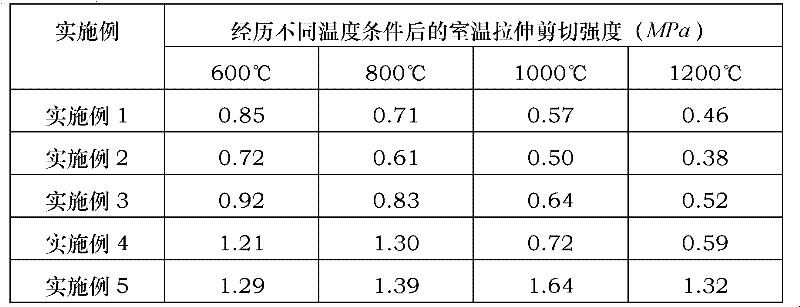

[0017] A microwave-curable adhesive of the present invention is prepared by adding 5-20 g of curing agent and 60-120 g of alumina powder into 100 ml of aluminum dihydrogen phosphate solution, and mixing them uniformly at a temperature of 15-40°C .

[0018] In the present invention, the aluminum dihydrogen phosphate solution that uses adopts following preparation method as: (A) add the phosphoric acid solution of 85wt% (mass percentage concentration) and add appropriate amount of deionized water to adjust the phosphoric acid that obtains 60wt% (mass percentage concentration) Solution; (B) heating the phosphoric acid solution of 60wt% (mass percentage concentration) to 110-120°C, and adding aluminum hydroxide powder (the particle size of the aluminum hydroxide powder is less than 50nm) during the heating process, cooling to 15-40°C , to obtain a tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com