Slag based mesoporous material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

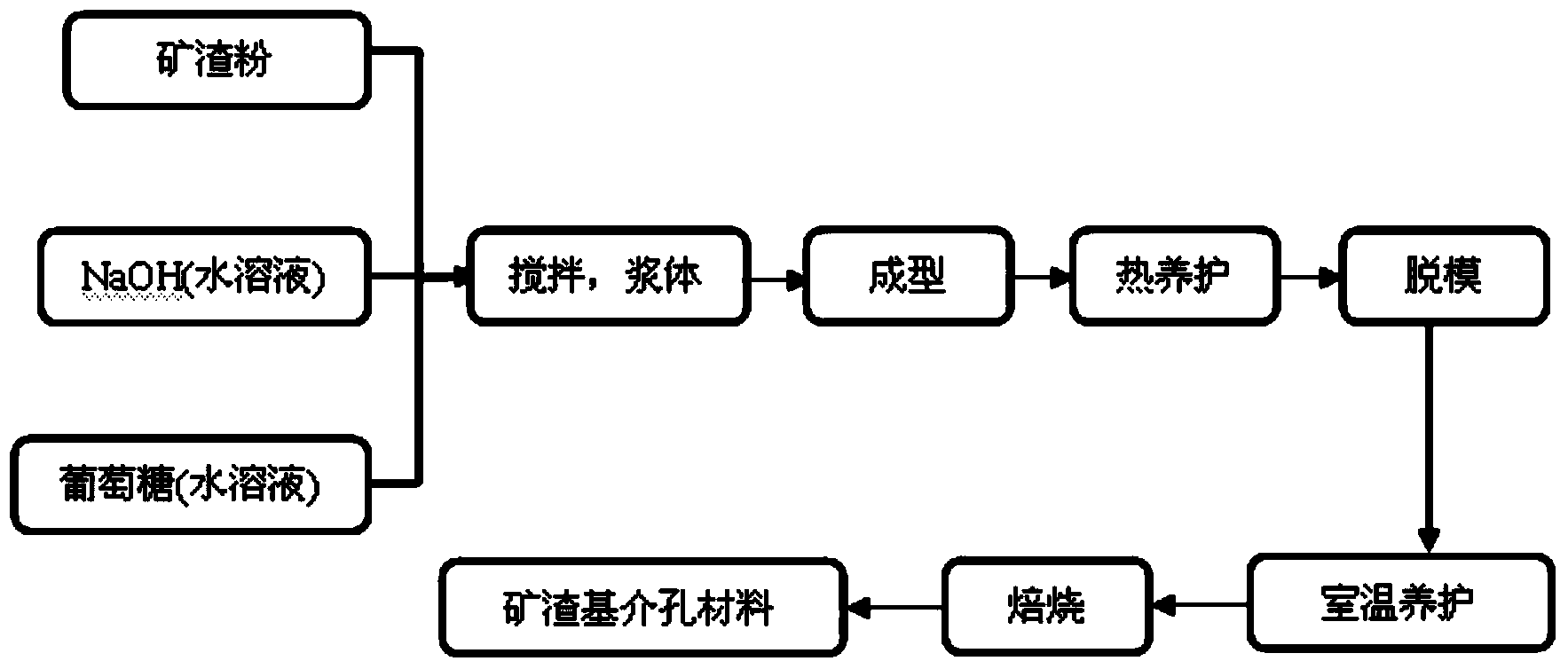

Method used

Image

Examples

Embodiment 1

[0051] Accurately weigh 600g of slag powder on this basis (100%); using the external mixing method, the sodium hydroxide content is 6% of the slag powder mass, and the ratio of water to slag powder mass is 0.28.

[0052] At room temperature, dissolve sodium hydroxide into water to form an aqueous sodium hydroxide solution. Pour the aqueous solution into a two-rotation two-speed pure slurry mixer, then add slag powder for mixing to form a uniform slurry, and put the slurry into a 31.5mm×31.5mm×50mm steel triple mold for forming, and place the triple mold Put it into a plastic film sealed bag, cure for 6 hours in a thermostat at 80°C, remove the mold after cooling, and cure for 1 day at room temperature to obtain a test block of slag-based cementitious material, and its compressive strength is determined to be 41MPa.

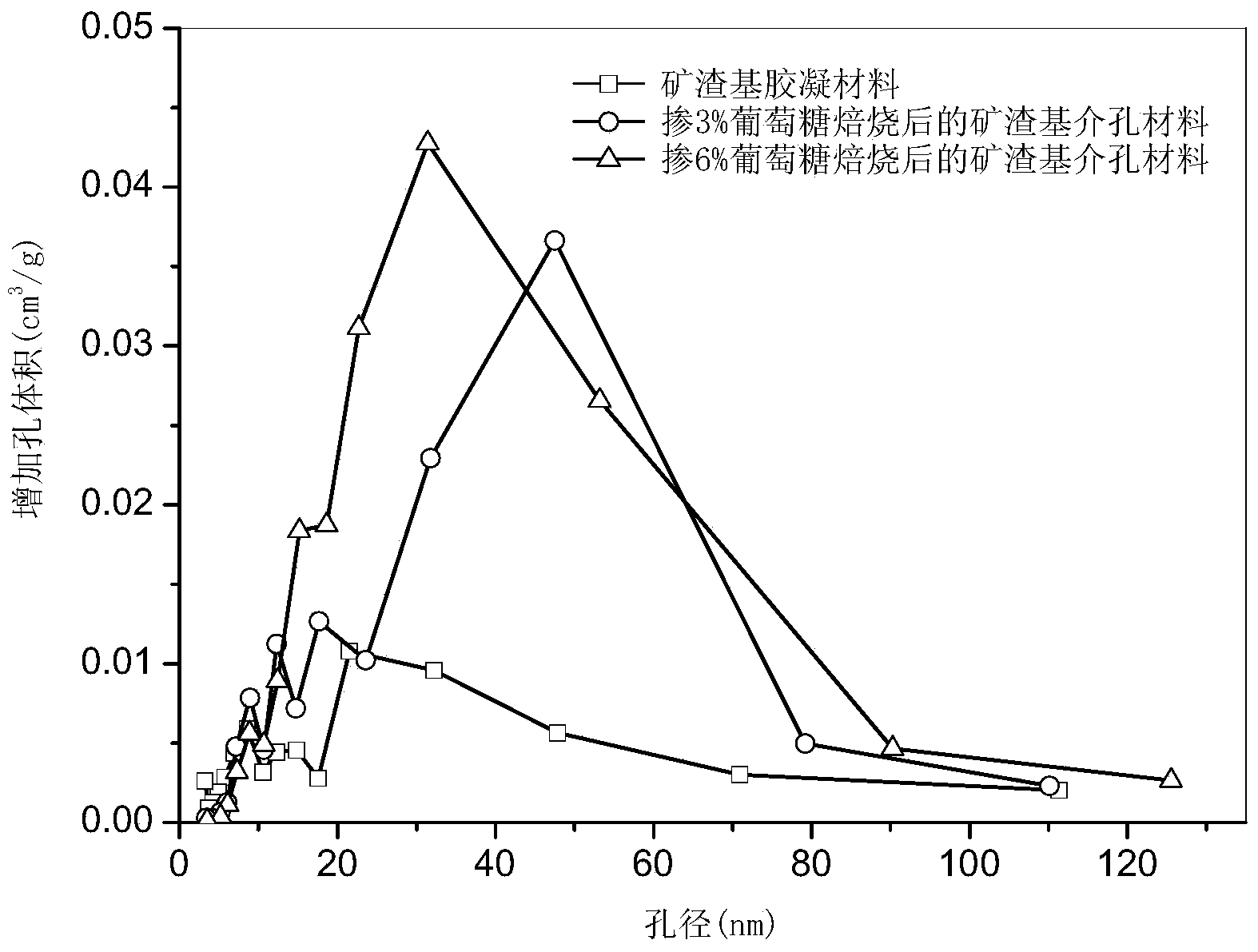

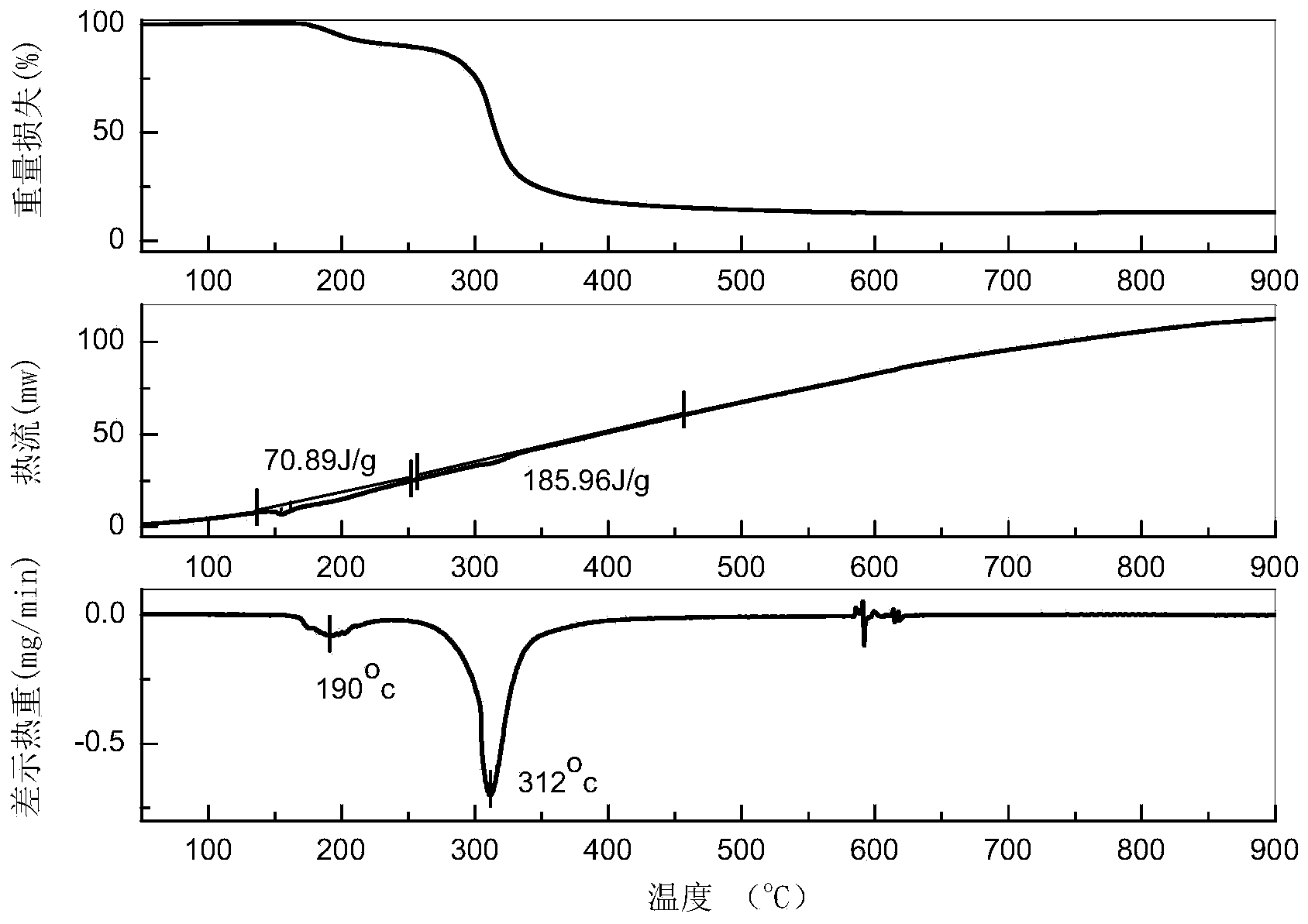

[0053] Put the slag-based cementing material test block into a horse boiling furnace, heat it up to 450°C at a heating rate of 5°C / min, keep it for 4h, let it cool nat...

Embodiment 2

[0057] Accurately weigh 600g of slag powder on this basis (100%); using the external mixing method, the sodium hydroxide content is 6% of the slag powder mass, the pore enhancer glucose is 3% of the slag mass, water and The mass ratio of slag powder is 0.24. At room temperature, dissolve sodium hydroxide in water to form an aqueous sodium hydroxide solution; dissolve solid glucose into water to form an aqueous glucose solution. Pour the sodium hydroxide aqueous solution and the glucose aqueous solution into the double-rotation double-speed pure slurry mixer in turn, then add the slag powder for mixing to form a uniformly mixed slurry, and fill the slurry into a 31.5mm×31.5mm×50mm steel triple Molding in the mold, put the triple mold into a plastic film sealed bag, and cure for 6 hours at 80°C in a constant temperature box, cool and remove the mold, and cure for 1 day at room temperature to obtain a test block of slag-based cementitious material, and test its compressive strengt...

Embodiment 3

[0061] Accurately weigh 600g of slag powder on this basis (100%); using the external mixing method, the sodium hydroxide content is 6% of the slag powder mass, the pore enhancer glucose is 6% of the slag mass, water and The mass ratio of slag powder is 0.24. At room temperature, dissolve solid sodium hydroxide into water to form an aqueous sodium hydroxide solution. The solid glucose is dissolved in water to form an aqueous glucose solution. Add the sodium hydroxide aqueous solution and the glucose aqueous solution to the two-rotation two-speed pure slurry mixer in turn, and then add the slag powder for mixing to form a uniformly mixed slurry, and put the slurry into a 31.5mm×31.5mm×50mm steel triple mold In the middle molding, the triple mold is placed in a plastic film sealed bag, cured for 6 hours at 80°C in a thermostat, cooled and removed, and cured at room temperature for 1 day to obtain a slag-based cemented test block. The compressive strength of the test block is 54.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com