Resource utilization type steel-slag concrete

A technology of concrete and section steel, which is applied in the field of building materials, can solve the problems of restricting the effective use of steel slag, complex composition of steel slag, and large fluctuations, and achieve the effects of promoting the development of circular economy, important social benefits, and increasing added value

Inactive Publication Date: 2012-10-03

SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS +1

View PDF6 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, due to the difference in smelting process and steel slag treatment process, the composition of steel slag is complex and fluctuates greatly, especially the stability of converter steel slag restricts the effective utilization of steel slag

The application of steel slag micropowder to concrete is relatively extensive, but the application of steel slag fine aggregate and steel slag coarse aggregate to concrete, especially the application of steel slag coarse aggregate with large particle size to concrete, is currently seldom studied.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

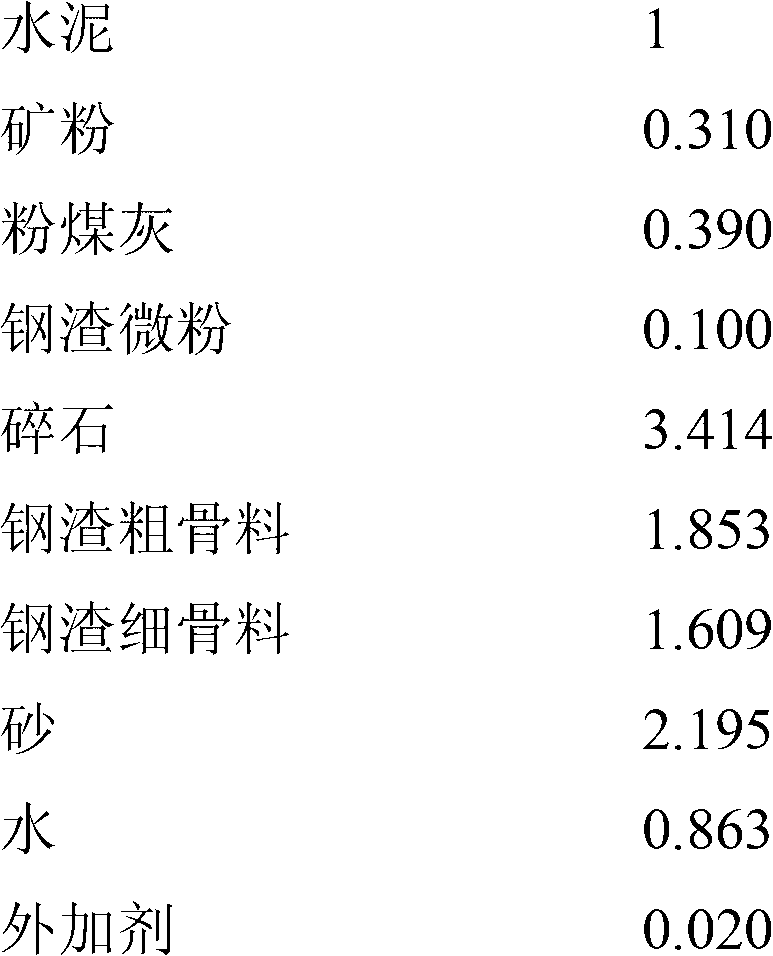

Embodiment 1

[0021] Prepare the steel slag concrete of strength grade C30, each raw material and its weight ratio are as follows:

[0022]

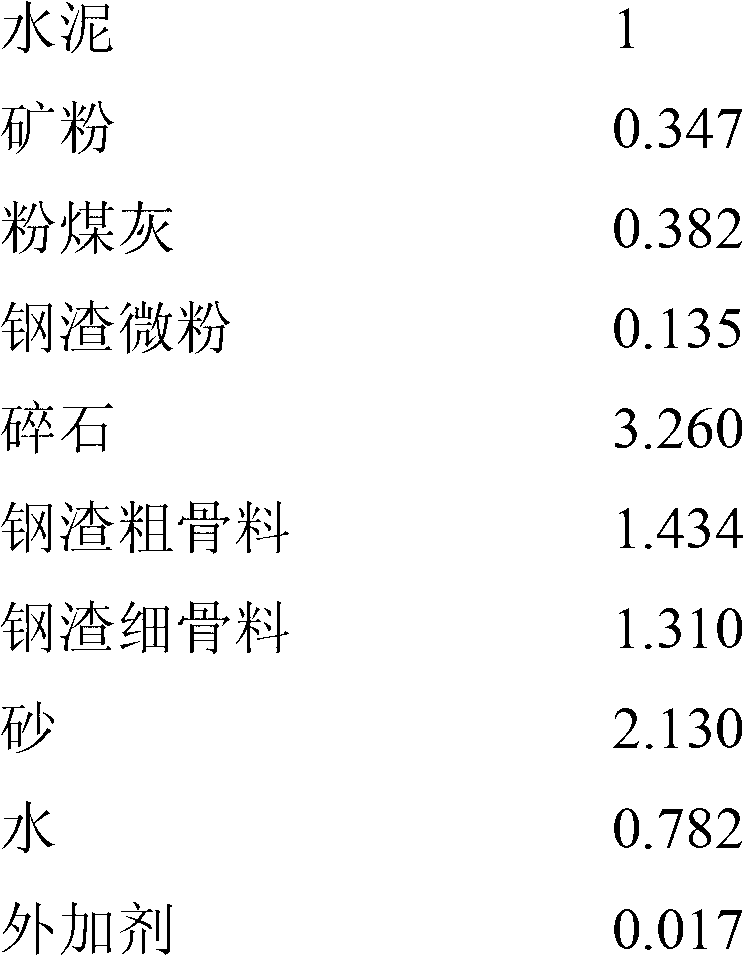

Embodiment 2

[0024] Prepare the steel slag concrete of strength grade C40, each raw material and its weight ratio are as follows:

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a resource utilization type steel-slag concrete. The resource utilization type steel-slag concrete is characterized in that the volume weight is 2400 -2600kg / m3, and the raw material components and the weight part of each component based on the mass percentage of cement are as follows: 1.000 parts of cement, 0.300-0.350 parts of mineral powder, 0.350-0.400 parts of coal ash, 0.100-0.150 parts of steel-slag fine powder, 1.300-1.650 parts of steel-slag fine aggregate, 1.400-1.900 parts of steel-slag rough aggregate, 2.000-2.200 parts of sand, 3.200-3.450 parts of broken stone, 0.700-0.900 parts of water, and 0.015-0.025 parts of additive. In comparison with the normal concrete, the resource utilization type steel-slag concrete provided by the invention has the advantages that the total content of solid wastes such as steel-slag and coal ash is higher than 30%; with the adoption of the industrial solid slag, the additional value is enhanced, the production cost is reduced, and meanwhile, the environmental problem is solved; the prepared concrete has good compactness and excellent mechanical property.

Description

technical field [0001] The invention relates to the field of building materials, in particular to a steel slag concrete for resource utilization, which is a concrete mixed with steel slag fine powder, steel slag fine aggregate with a particle size of 0-5 mm and steel slag coarse aggregate with a particle size of 5-25 mm . Background technique [0002] The Twelfth Five-Year Plan requires vigorously promoting the development of circular economy and improving the utilization rate of bulk industrial solid waste such as steel slag. Steel slag is solid waste slag in the steelmaking process, and its discharge per ton of steel reaches 0.15-0.20 tons. my country's steel output ranks first in the world. After decades of exploration, my country has formed its own characteristics in steel slag treatment and utilization technology. Steel slag has been successfully used in sintering ingredients, cement production, engineering backfill materials, road subgrade materials, etc. [0003] Ho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/04C04B18/30

CPCY02W30/91

Inventor 徐兵顾文飞施钟毅於林峰康明朱柏龙林长农周维唐欧靖王琼

Owner SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com