Controlled-released fertilizer preparation method and commercial crop controlled-released fertilizer prepared according to controlled-released fertilizer preparation method

A technology for economic crops and slow and controlled release fertilizers, applied in the field of compound fertilizers, can solve the problems of long release period, fertilizer accumulation, excessive use of chemical fertilizers, etc., and achieve the effects of promoting early maturity, increasing growth rate, and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

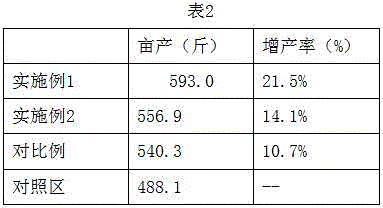

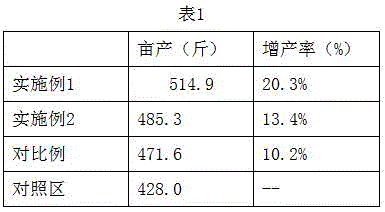

Examples

Embodiment 1

[0039] The preparation method of slow and controlled release fertilizer for economic crops of the present invention comprises the following steps:

[0040] (1) Weigh each raw material according to the following formula: 100 parts of sodium tripolyphosphate alkali residue, 35 parts of bagasse, 20 parts of fish pond sludge, 6 parts of gibberellin bacteria residue, 6 parts of Sophora flavescens aerial part, 20 parts of holly leaves 12 parts of wormwood, 16 parts of mixed bacteria, 38 parts of seaweed slag, 18 parts of cinder, 8 parts of bamboo charcoal, 35 parts of diammonium phosphate, 22 parts of superphosphate, 35 parts of urea, and 26 parts of potassium chloride; The formula takes sodium tripolyphosphate alkali slag, according to the insoluble P 2 o 5 The theoretical amount of papermaking black liquor is added to it, and the temperature is controlled at 80-85°C for stirring reaction, so that the insoluble P in sodium tripolyphosphate alkali slag 2 o 5 into soluble P 2 o ...

Embodiment 2

[0047] The preparation method of slow and controlled release fertilizer for economic crops of the present invention comprises the following steps:

[0048] (1) Weigh each raw material according to the following formula: 80 parts of sodium tripolyphosphate alkali residue, 40 parts of bagasse, 15 parts of fish pond sludge, 10 parts of gibberellin bacteria residue, 5 parts of aboveground part of Sophora flavescens, 25 parts of holly leaves 10 parts of wormwood, 20 parts of mixed bacteria, 35 parts of seaweed slag, 20 parts of cinder, 5 parts of bamboo charcoal, 40 parts of diammonium phosphate, 25 parts of superphosphate, 30 parts of urea, and 30 parts of potassium chloride; The formula takes sodium tripolyphosphate alkali slag, according to the insoluble P 2 o 5 The theoretical amount of papermaking black liquor is added to it, and the temperature is controlled at 80-85°C for stirring reaction, so that the insoluble P in sodium tripolyphosphate alkali slag 2 o 5 into soluble ...

Embodiment 3

[0055] According to the method of Example 1, slow-release fertilizers for economic crops are prepared. The difference is that the following raw materials are used in parts by weight as follows: 120 parts of sodium tripolyphosphate alkali residue, 30 parts of bagasse, 25 parts of fish pond sludge, gibberella 5 parts of vegetable residue, 10 parts of Sophora flavescens, 15 parts of holly leaves, 15 parts of wormwood, 15 parts of mixed bacteria, 40 parts of seaweed residue, 15 parts of coal cinder, 10 parts of bamboo charcoal, 30 parts of diammonium phosphate, heavy Calcium phosphate 20 parts, urea 40 parts, potassium chloride 25 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com