Method for smelting tungsten-molybdenum-iron alloy from tungsten-molybdenum associated mineral

A technology for associated ore and ferroalloy, applied in the field of tungsten-molybdenum associated ore smelting tungsten-molybdenum ferroalloy, can solve problems such as difficulty in realizing mass production and smelting scale limitation, and achieve the effect of comprehensive utilization of resources, saving cost of raw materials and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

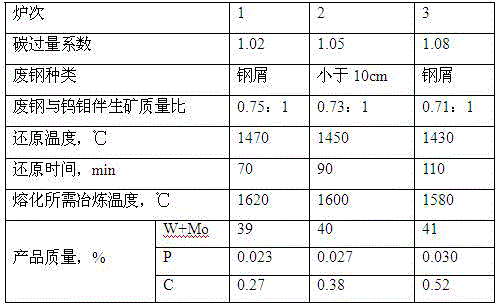

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific examples. In the present invention, unless otherwise specified, the content of each component represents the content of mass percentage.

[0031] The composition of tungsten and molybdenum associated ore used in the examples is shown in Table 2. The melting point of steel scrap composition is 1520°C, and it contains 0.15% carbon, 0.015% P and 0.015% S. Among the carbonaceous reducing agents used, the fixed carbon is 85%, the volatile matter is 8%, and the ash content is 6%. The binder is an organic binder, and the amount of the binder is 3%. Formed with a ball press. The dryer adopts an electric drying box. The capacity of the induction heating furnace is 5 tons, and it is protected by nitrogen gas, and the flow rate of nitrogen gas is 0.1~1m 3 / min.

[0032] Chemical composition (%) of tungsten and molybdenum associated ore in the embodiment of table 2

[0033] WO 3

MoO 3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com