Process for smelting ferrovanadium by extraction of vanadium from vanadium-containing errophosphorus

A technology containing vanadium-phosphorus iron and vanadium-phosphorus iron, which is applied in the field of metallurgy, can solve problems such as failure to reach the smelting temperature, failure to work, failure to extract, etc., and achieve the effect of less investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

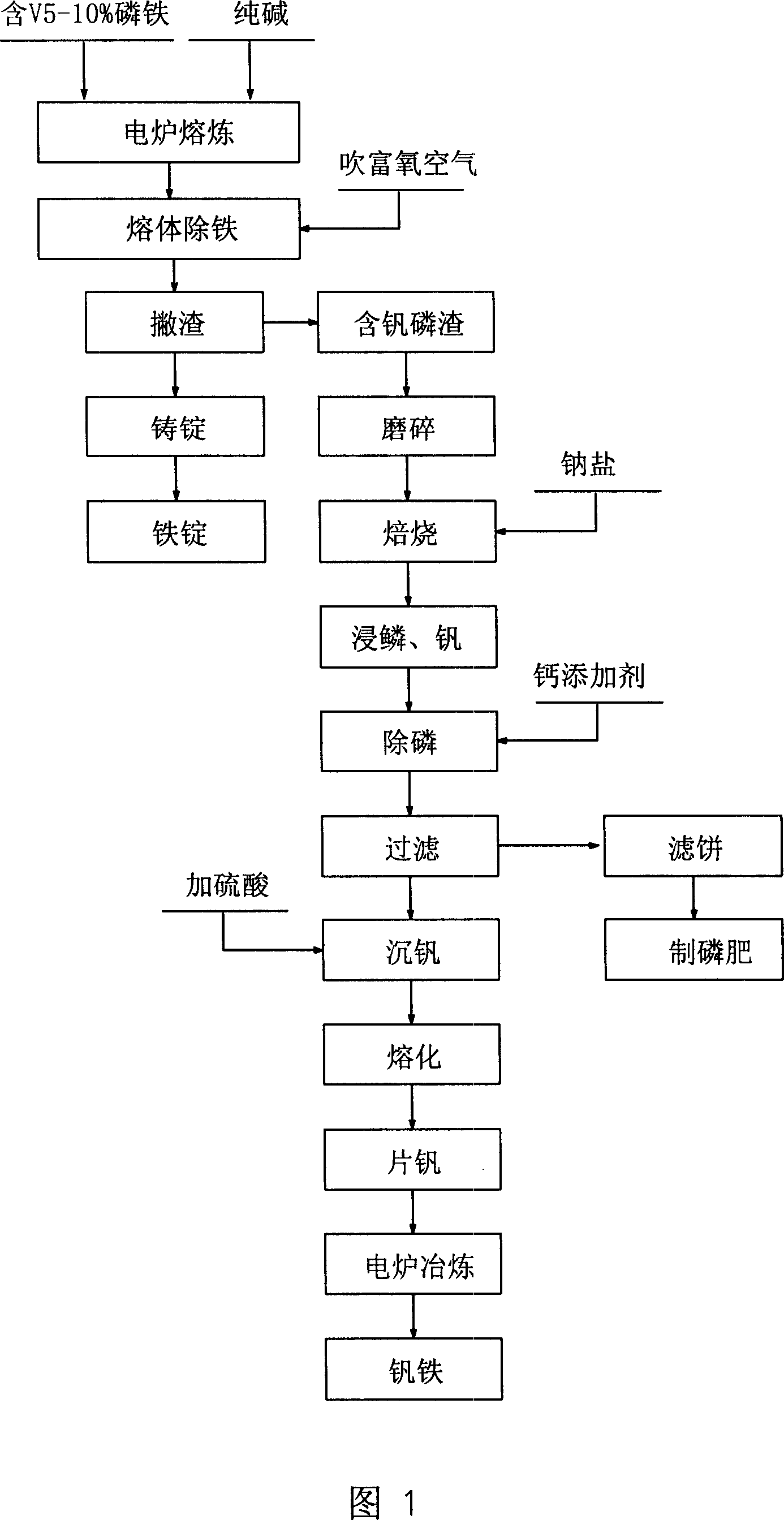

Image

Examples

Embodiment 1

[0017] The product that present embodiment produces is iron vanadium FeV-50-A, and its step is:

[0018] 1. First put vanadium-containing phosphorus iron (containing V5%) and NaCO3 into the electric furnace according to 1.5 times the ratio of V content, heat to 2000°C, pour it into the ladle after smelting for 2 hours, and pour it into the ladle when the temperature drops to 1400°C Oxygen-enriched air is blown into the melt to skim off the scum containing vanadium and phosphorus;

[0019] 2. Cool the molten iron ingot in the molten iron ladle into finished iron ingot;

[0020] 3. Cool and grind the scum containing vanadium and phosphorus in step 1 into powder (fineness up to 100 mesh), add sodium salt powder (sodium carbonate) to make pellets, and roast for 2 hours; the temperature of the roasting process is controlled at 900°C;

[0021] 4. Dissolve the soluble matter in the pellet into water by soaking the pellet in water to obtain a mixed solution of sodium vanadate and so...

Embodiment 2

[0026] The product that present embodiment produces is iron vanadium FeV-50-B, and its step is:

[0027] 1. First put vanadium-containing ferrophosphorus (containing V10%) and NaCO3 into the electric furnace according to 1 times the proportion of V, heat to 1600°C, pour it into the ladle after smelting for 2 hours, and pour it into the ladle when the temperature drops to 1300°C Oxygen-enriched air is blown into the melt to skim off the scum containing vanadium and phosphorus;

[0028] Steps 2, 3, 4, 5 are the same as in Example 1.

Embodiment 3

[0030] The product that present embodiment produces is iron vanadium FeV-75-A, and its step is:

[0031] 1. First, put steelmaking high-phosphorus vanadium slag (containing V8%) and NaCO3 into the electric furnace at a ratio of 1.2 times the V content, heat it to 1900°C, pour it into the ladle after smelting for 2 hours, and when the temperature drops to 1380°C Oxygen-enriched air is blown into the melt from time to time to skim off the scum containing vanadium and phosphorus;

[0032] Steps 2, 3, 4, 5 are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com