Method for preparing free cutting steels and slag phosphate fertilizers using phosphorus-rich sulfur-rich iron powder

A technology of steel slag phosphate fertilizer and free-cutting steel, applied in phosphate fertilizer, Thomas phosphate fertilizer, fertilization device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

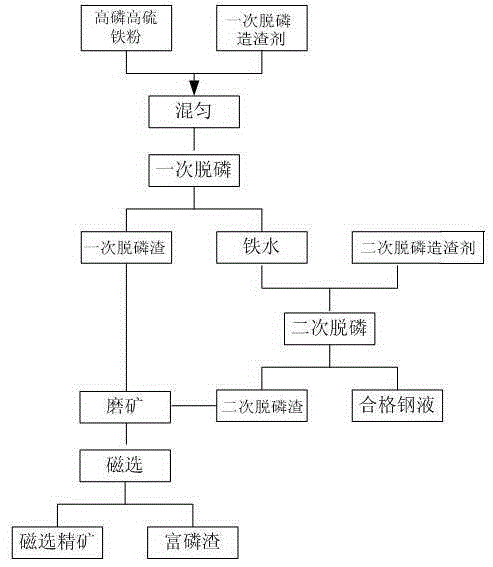

Image

Examples

Embodiment 1

[0027] The high phosphorus and high sulfur iron powder used in this embodiment contains MFe84.17%, P1.74%, S0.22%, C0.19%, SiO 2 2.15%, Al 2 o 3 1.21%, FeO10.32%, adopt its method for preparing free-cutting steel and steel slag phosphate fertilizer to carry out according to the following steps:

[0028] (1) Mix the high-phosphorus and high-sulfur iron powder with the primary dephosphorization slagging agent. The primary dephosphorization slagging agent consists of 60% CaO and 40% Fe 2 o 3 Composition, the amount of primary dephosphorization slagging agent accounted for 13% of the weight of iron powder, mixed evenly and put into the reaction tank, at room temperature, put the reaction tank into the reaction furnace, control the temperature of the reaction furnace to 1590 ° C, Insulate for 11 minutes to perform a dephosphorization, and get molten iron and a dephosphorization slag after removing the slag;

[0029] (2) Add the secondary dephosphorization slagging agent to the ...

Embodiment 2

[0032] Contain MFe84.92%, P1.79%, S0.25%, C0.24%, SiO in the high phosphorus high sulfur iron powder in the present embodiment by weight percentage 2 2.01%, Al 2 o 3 1.32%, FeO9.47%, adopt its method for preparing free-cutting steel and steel slag phosphate fertilizer to carry out according to the following steps:

[0033] (1) Mix the high-phosphorus and high-sulfur iron powder with the primary dephosphorization slagging agent. The primary dephosphorization slagging agent consists of 70% CaO and 30% Fe 2 o 3 Composition, the amount of primary dephosphorization slagging agent accounted for 12% of the weight of iron powder, mixed evenly and put into the reaction tank, at room temperature, put the reaction tank into the reaction furnace, control the temperature of the reaction furnace to 1580 ° C, Insulate for 12 minutes to perform a dephosphorization, and get molten iron and a dephosphorization slag after removing the slag;

[0034] (2) Add a secondary dephosphorization slag...

Embodiment 3

[0037] Contain MFe84.92%, P1.79%, S0.25%, C0.24%, SiO in the high phosphorus high sulfur iron powder in the present embodiment by weight percentage 2 2.01%, Al 2 o 3 1.32%, FeO9.47%, adopt its method for preparing free-cutting steel and steel slag phosphate fertilizer to carry out according to the following steps:

[0038] (1) Mix the high-phosphorus and high-sulfur iron powder with the primary dephosphorization slagging agent. The primary dephosphorization slagging agent consists of 65% CaO and 35% Fe 2 o 3 Composition, the amount of primary dephosphorization slagging agent accounted for 14% of the weight of iron powder, mixed evenly and put into the reaction tank, at room temperature, put the reaction tank into the reaction furnace, control the temperature of the reaction furnace to 1600 ° C, Insulate for 10 minutes to perform a dephosphorization, and get molten iron and a dephosphorization slag after removing the slag;

[0039] (2) Add a secondary dephosphorization slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com