Material for phosphate fertilizer and for producing thereof

A technology for phosphate fertilizer and raw materials, which is applied in the directions of phosphate fertilizer granulation/granulation, phosphate fertilizer, inorganic fertilizer, etc., can solve the problems of reduced concentration of molten iron P, insoluble phosphoric acid, and inability to obtain fertilizer characteristics, and achieves low cost and high dephosphorization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

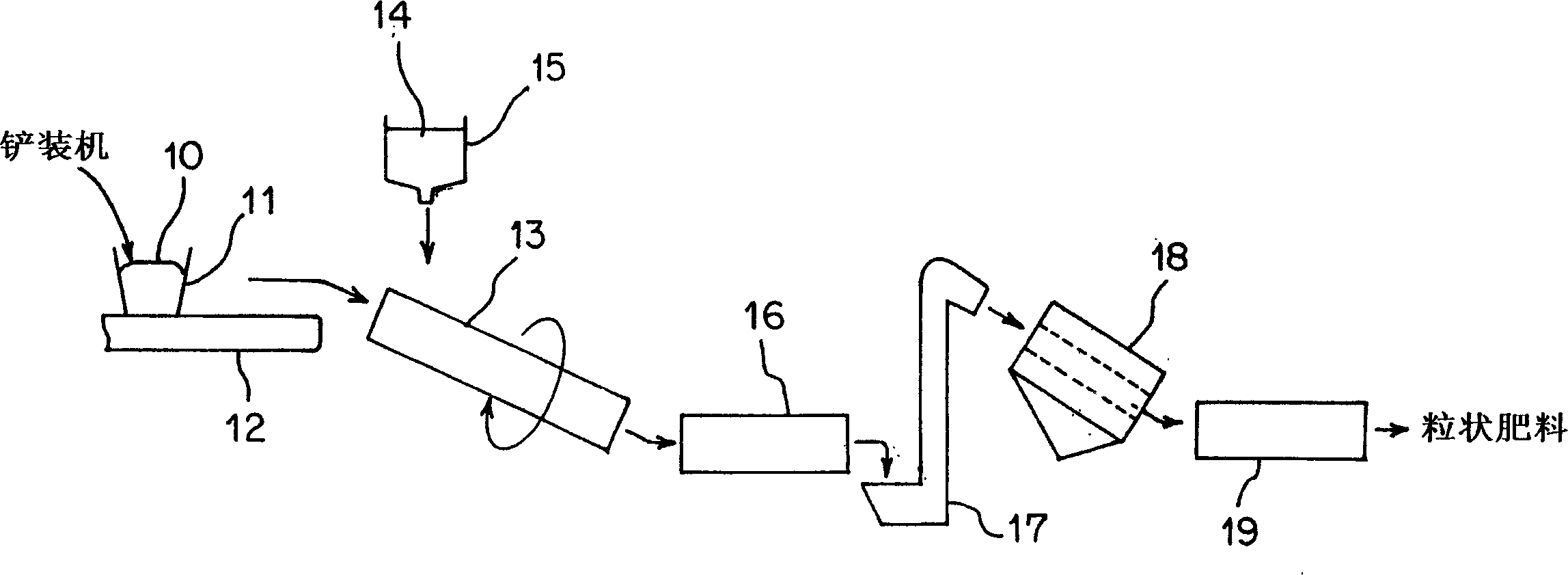

[0231] A 300t converter is used for dephosphorization reaction treatment of blast furnace molten iron. In this dephosphorization reaction treatment, after the molten iron is loaded into the converter, a specified amount of CaO source is added, and oxygen blowing is carried out from the top blowing lance. In addition, dephosphorization reaction treatment was performed for the same treatment time in both the examples of the present invention and the comparative examples.

[0232] In the comparative example, the molten iron after tapping does not carry out desiliconization treatment, but implements dephosphorization reaction treatment. Desiliconization: Desiliconization treatment is performed to reduce the Si content to 0.07% by mass or less, and then dephosphorization reaction treatment is performed. In the example of the present invention, CaF is not added 2 .

[0233]Table 2 shows the dephosphorization reaction treatment conditions and the composition of the produced slag. ...

Embodiment 2

[0236] The molten iron tapped from the blast furnace is desiliconized in the casting house and in the ladle as needed, desulfurized in the ladle by mechanical stirring, and dephosphorized in a 250-ton converter. The temperature of the molten iron before and after the dephosphorization reaction is 1250-1350°C. The source of CaO is quicklime mainly CaO, and the sieve with a particle size below 200 mesh is used. According to the difference of Si concentration in the molten iron, the unit consumption of CaO is 5~15kg / ton of molten iron.

[0237] Such as Figure 10 As shown, in this dephosphorization reaction treatment, the CaO source is sprayed onto the bath surface through a top blowing lance with oxygen as the carrier gas, and the CaO source and the oxygen source are supplied (blowing time: 10 minutes). Speed A (Nm 3 / min / ton of molten iron) and the ratio A / B of the CaO source supply rate B (kg / min / ton of molten iron) are operated under various conditions. In addition witho...

Embodiment 3

[0245] The molten iron tapped from the blast furnace is desiliconized in the casting house and in the ladle as needed, desulfurized in the ladle by mechanical stirring, and dephosphorized in a 250-ton converter. The temperature of the molten iron at the end of the dephosphorization reaction treatment is 1360-1450° C., the CaO source is quicklime mainly CaO, and the undersieve with a particle size of 200 mesh or less is used.

[0246] Such as Figure 10 As shown, in this dephosphorization reaction treatment, the oxygen supply rate A (Nm 3 / min / ton of molten iron) and CaO source supply rate B (kg / min / ton of molten iron) ratio A / B satisfies the condition of 0.3-7 to supply CaO source and oxygen source (blowing time: 10 minutes). In addition without adding CaF 2 .

[0247] Nitrogen as a stirring gas is 0.05-0.15Nm 3 / min / ton The flow rate of molten iron is sprayed from the bottom blowing nozzle at the bottom of the furnace to the molten iron.

[0248] Table 4 shows the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com