Active phosphate fertilizer as well as preparation method and application thereof

A phosphate fertilizer, active technology, applied in the direction of phosphate fertilizer, application, Thomas phosphate fertilizer, etc., can solve the problem of unsatisfactory activation and dephosphorization effect, and does not solve the problem of phosphorus activation, release and re-fixation, etc., to achieve rich content, easy implementation, and improved fertilizer utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

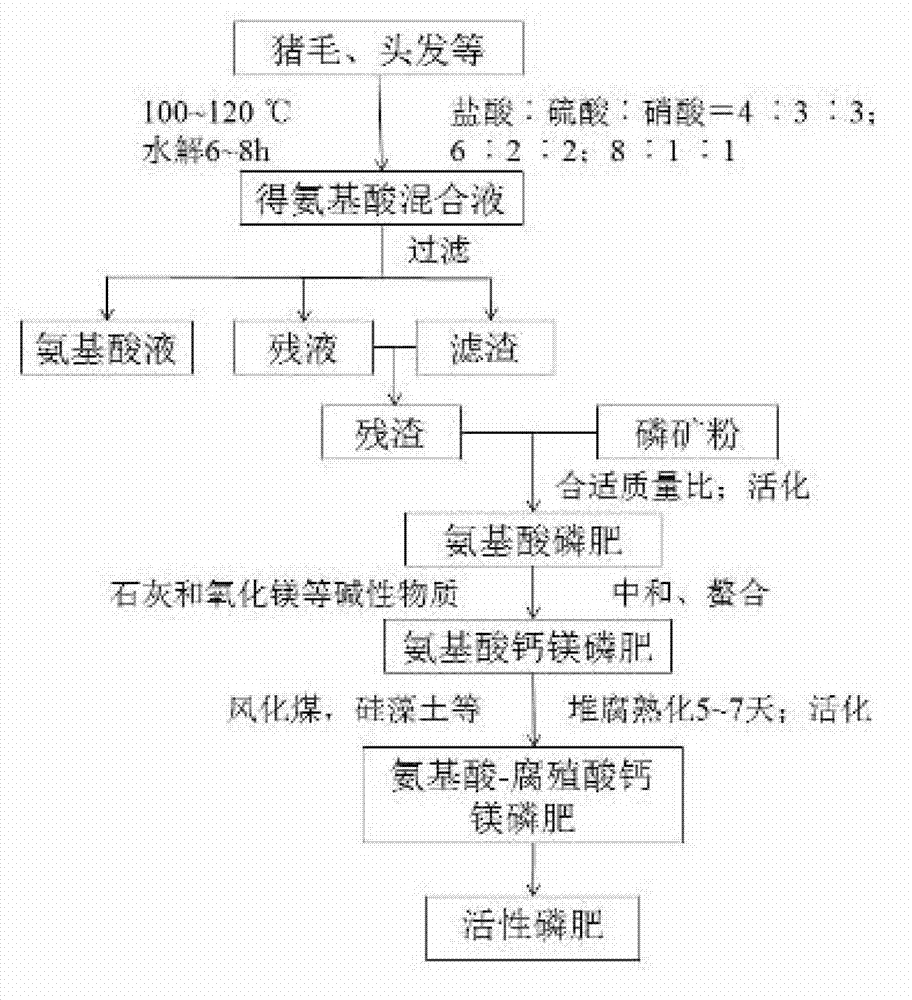

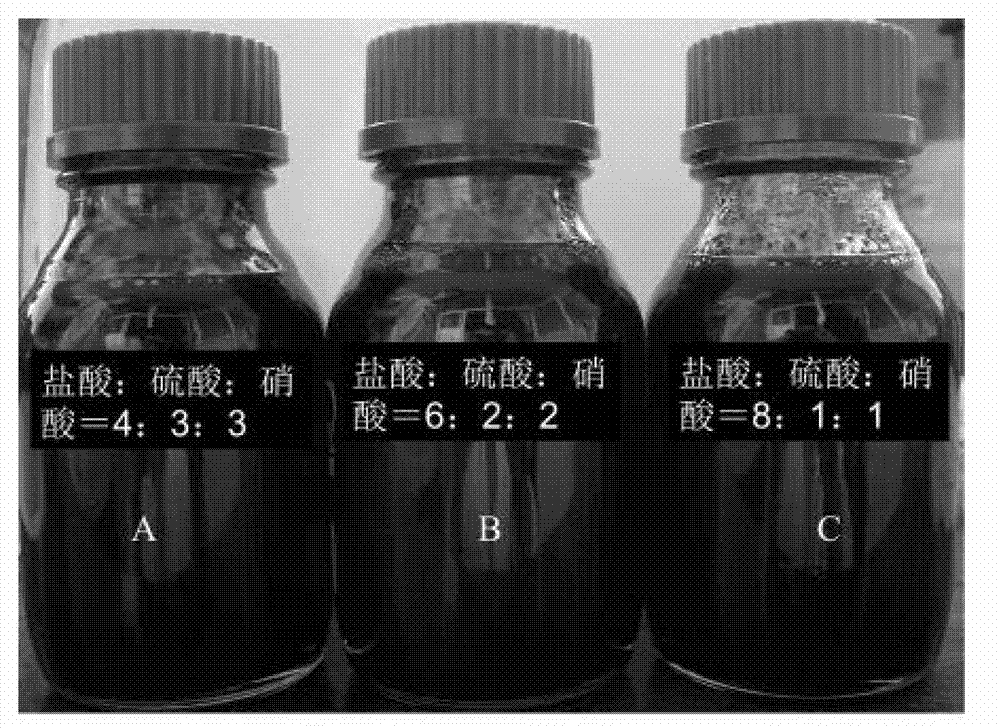

[0044] (1) Hydrolysis: add the crushed pig hair to the reactor, and then hydrolyze the mixed acid with 15wt% hydrochloric acid, 15wt% nitric acid and 20wt% sulfuric acid in a ratio of 4:3:3 by mass. The mass ratio of the mixed acid is 1:1.6. After 30 minutes, the temperature is raised to 110°C and hydrolyzed for 6 hours to obtain an amino acid mixture such as figure 2 Shown in A.

[0045] (2) Filtration: After hydrolysis, let it stand for 2 hours, and filter after cooling to obtain amino acid liquid and amino acid residue.

[0046] (3) Activation: Add the filtered amino acid residue to the phosphate rock powder, the mass ratio of the phosphate rock powder to the amino acid residue is 3:1; add an appropriate amount of water (10% of the mass of the phosphate rock powder), and stir for 30 minutes.

[0047] (4) Neutralization: After activation, add lime and magnesium oxide for neutralization; the added amount of lime and magnesium oxide is 8% of the mass of the amino acid residue.

[004...

Embodiment 2

[0052] (1) Hydrolysis: add the crushed pig hair to the reactor, and then hydrolyze the mixed acid with 15wt% hydrochloric acid, 15wt% nitric acid and 20wt% sulfuric acid in a ratio of 4:3:3 by mass. The mass ratio of the mixed acid is 1:1.6. After 30 minutes, the temperature is raised to 110°C and hydrolyzed for 6 hours to obtain an amino acid mixture such as figure 2 Shown in A.

[0053] (2) Filtration: After hydrolysis, let it stand for 2 hours, and filter after cooling to obtain amino acid liquid and amino acid residue.

[0054] (3) Activation: Add the filtered amino acid residue to the phosphate rock powder, the mass ratio of the phosphate rock powder to the amino acid residue is 5:1; add an appropriate amount of water (10% of the mass of the phosphate rock powder), and stir for 30 minutes.

[0055] (4) Neutralization: After activation, add lime and magnesium oxide for neutralization. The addition amount of lime and magnesium oxide is 9% of the mass of the amino acid residue.

[...

Embodiment 3

[0060] (1) Hydrolysis: Put the crushed pig hair into the reactor, and then hydrolyze the mixed acid composed of 25wt% hydrochloric acid, 25wt% nitric acid and 40wt% sulfuric acid in a mass ratio of 6:2:2. The pig hair and the mixed acid The mass ratio is 1:2. After 2 hours, the temperature is raised to 120°C and hydrolyzed for 8 hours to obtain an amino acid mixture such as figure 2 Shown in B.

[0061] (2) Filtration: After hydrolysis, let it stand for 6 hours, and filter after cooling to obtain amino acid liquid and amino acid residue.

[0062] (3) Activation: Add the filtered amino acid residue to the phosphate rock powder, the mass ratio of the phosphate rock powder to the amino acid residue is 3:1; add an appropriate amount of water (10% of the mass of the phosphate rock powder), and stir for 30 minutes.

[0063] (4) Neutralization: After activation, add lime and magnesium oxide for neutralization. The addition amount of lime and magnesium oxide is 8% of the mass of the amino a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com