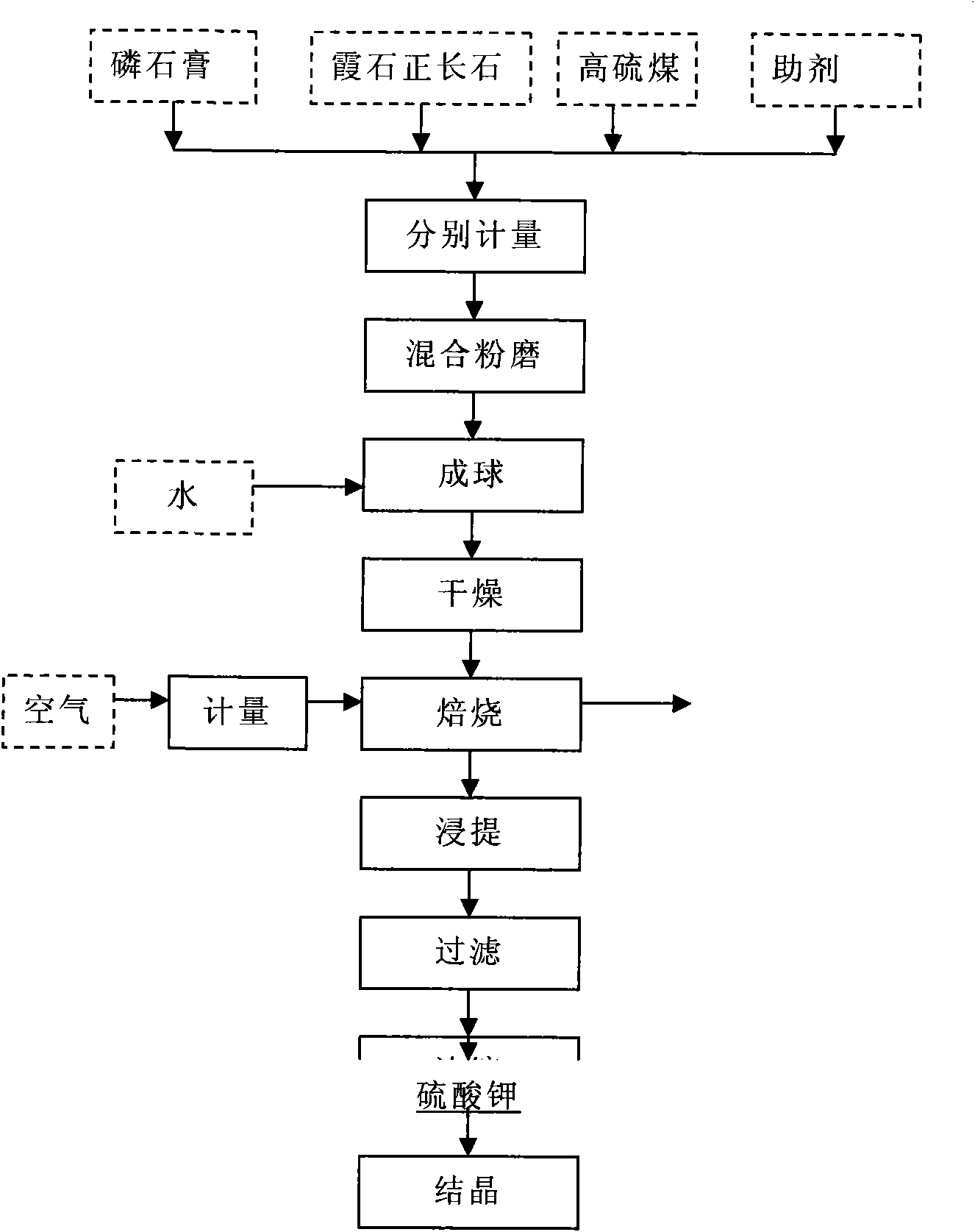

Preparation method for preparing potash fertilizer and producing sulfuric acid simultaneously employing mineral with potassium, ardealite and high-sulphur coal

A technology of phosphogypsum and high-sulfur coal, which is applied in the field of preparation of potash fertilizer and co-production of sulfuric acid, can solve environmental pollution and other problems, and achieve the effects of low equipment investment, low comprehensive production cost and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]1) Formula composition (substance measurement units are parts by mass):

[0029] (1) Potassium feldspar: 65 parts, phosphogypsum: 31 parts, high-sulfur coal: 4 parts;

[0030] (2) The auxiliary agent is sodium fluoride, and the consumption is 1% of potassium feldspar;

[0031] 2) Process method:

[0032] After blending the above formula, grind it in a ball mill to form a powder with a particle size of less than 0.08mm accounting for 95%, add water to form a ball, bake it in a drying oven at 105°C for 4 hours, and put it into a tube with a set temperature of 950°C In the furnace, the inlet valve connected to the porcelain tube is closed, and the outlet is inserted into the water seal tank. The temperature rise rate of the tube furnace is 20°C / min. When the temperature rises to 1200°C, it is maintained for 10 minutes, then oxygen is introduced, and the inlet and outlet valves are opened at the same time. The oxygenation time is 20 minutes in total, the oxygen flow rate ...

Embodiment 2

[0036] 1) Formula composition (substance measurement units are parts by mass):

[0037] (1) Potassium feldspar: 32 parts, phosphogypsum: 61 parts, high-sulfur coal: 7 parts;

[0038] (2) The auxiliary agent is sodium hydroxide, and the consumption is 1.5% of potassium feldspar;

[0039] 2) Process method:

[0040] Blend the materials of the above formula (1) and grind them in a ball mill to form a powder with a particle size of less than 0.08mm accounting for 96.3%, add an aqueous solution dissolved in sodium hydroxide and pressurize it into a cake shape, and dry it in a desiccator at 105°C After 4 hours, take it out and crush it, take the mixture with a particle size of 5-10 mm and put it into a tube furnace with a set temperature of 1200 ° C, close the inlet valve connected to the porcelain tube, and insert the outlet into a water-sealed tank. The heating rate of the tube furnace is 20°C / min. When the temperature rises to 1200°C and maintains for 10 minutes, oxygen is intr...

Embodiment 3

[0044] 1) Formula composition (substance measurement units are parts by mass)

[0045] (1) Potassium feldspar: 65 parts, phosphogypsum: 31 parts, high-sulfur coal: 4 parts;

[0046] (2) The auxiliary agent is calcium fluoride, and the consumption is 0.5% of potassium feldspar;

[0047] 2) Process method:

[0048] Grinding powder with a particle size of less than 0.08mm accounts for 95.60%. In the tube furnace with a set temperature of 1100°C, the temperature rise rate of the continuous tube furnace is 20°C / min. When the temperature rises to 1100°C, it is maintained for 10 minutes. Oxygen was introduced afterward, and the time of oxygen ventilation was 30 minutes in total. The first 10 minutes of oxygen ventilation was 3 liters / minute, and the last 20 minutes was 10 liters / minute. The rest of the operations are the same as above. The results are as follows: Sulfur is converted to SO 2 The conversion rate of 87.40%, the yield of soluble potassium is 97.06%, and the total con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com