Carbon-based compound fertilizer and biomass gas co-production technology based on municipal sludge

A technology of biomass gas and municipal sludge, which is applied in the direction of gasification process, fertilizer mixture, and manufacture of combustible gas, etc. It can solve the problems of secondary pollution of soil and crops, difficulty in effective utilization of urban sludge, and impossibility of fertilization treatment, etc. , to avoid pollution discharge, improve the ability of water and fertilizer retention, and improve the effect of fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

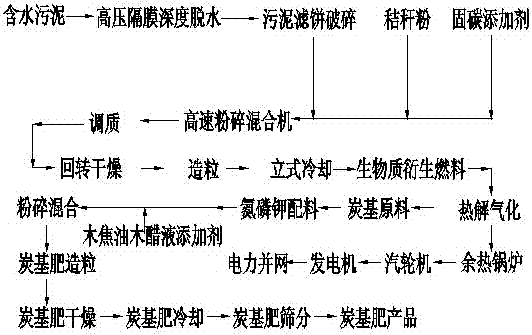

[0016] like figure 1 As shown, the preparation method of carbon-based high-efficiency organic-inorganic compound fertilizer in this embodiment includes the following steps: 1) Dehydration: the municipal sludge from the sewage treatment plant is dehydrated to a water content of 45% through a high-pressure diaphragm to obtain a sludge filter cake ;2) Crushing: crushing the sludge filter cake into sludge particles; 3) Mixing: mixing 53% of sludge particles, 40% of straw powder, and 7% of carbon-fixing additives, of which the carbon-fixing additives Contains 50% diatomite, 20% calcium oxide and 30% magnesium ore powder, all are percentages by mass, and the particle size of the three components is 60 mesh; 4) Conditioning process, by extruding the mixed material 5) Drying: Reduce the moisture content of the mixed material to 15% through a rotary dryer; 6) Pelletizing: Obtain biomass-derived fuel particles through a granulator; The fuel particles are air-cooled to solidify the part...

Embodiment 2

[0018] The preparation method of carbon-based high-efficiency organic-inorganic compound fertilizer in this embodiment includes the following steps: 1) dehydration: dehydrate the urban sludge from the sewage treatment plant to a water content of 55% through a high-pressure diaphragm to obtain a sludge filter cake; 2) Crushing: breaking the sludge filter cake into sludge particles; 3) Mixing: mixing 92% of sludge particles, 5% of straw powder, and 3% of carbon-fixing additives, of which the carbon-fixing additives contain 60% diatomite, 25% calcium oxide, and 15% magnesium ore powder, all of which are percentages by mass, and the particle diameters of the three components are all 80 mesh; 4) conditioning process, by extruding the mixed material to Increase density and reduce moisture; 5) Drying: Reduce the moisture content of the mixed material to 40% through a rotary dryer; 6) Granulation: Obtain biomass-derived fuel particles through a pelletizer; 7) Cooling: Dry biomass-deriv...

Embodiment 3

[0020]The preparation method of carbon-based high-efficiency organic-inorganic compound fertilizer in this embodiment includes the following steps: 1) dehydration: dehydrate the urban sludge from the sewage treatment plant to a water content of 51% through a high-pressure diaphragm to obtain a sludge filter cake; 2) Crushing: breaking the sludge filter cake into sludge particles; 3) Mixing: mixing 91% of sludge particles, 1% of straw powder, and 8% of carbon-fixing additives, of which the carbon-fixing additives contain 53% diatomite, 30% calcium oxide, and 17% magnesium ore powder, all of which are percentages by mass, and the particle diameters of the three components are all 70 mesh; 4) conditioning process, by extruding the mixed material to Increase density and reduce moisture; 5) Drying: Reduce the moisture content of the mixed material to 26% through a rotary dryer; 6) Pelletizing: Obtain biomass-derived fuel particles through a pelletizer; 7) Cooling: Treat biomass-deri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com