Preparation for slow release glass potassic fertilizer by smelting iron and steel fag-end

A slow-release, waste-residue technology, applied in the direction of potash fertilizer, application, inorganic fertilizer, etc., can solve the problems of dissolution performance change, unstable fertilizer composition, dissolution composition variation, etc., to achieve small impact, good slow-release effect, The effect of stable ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

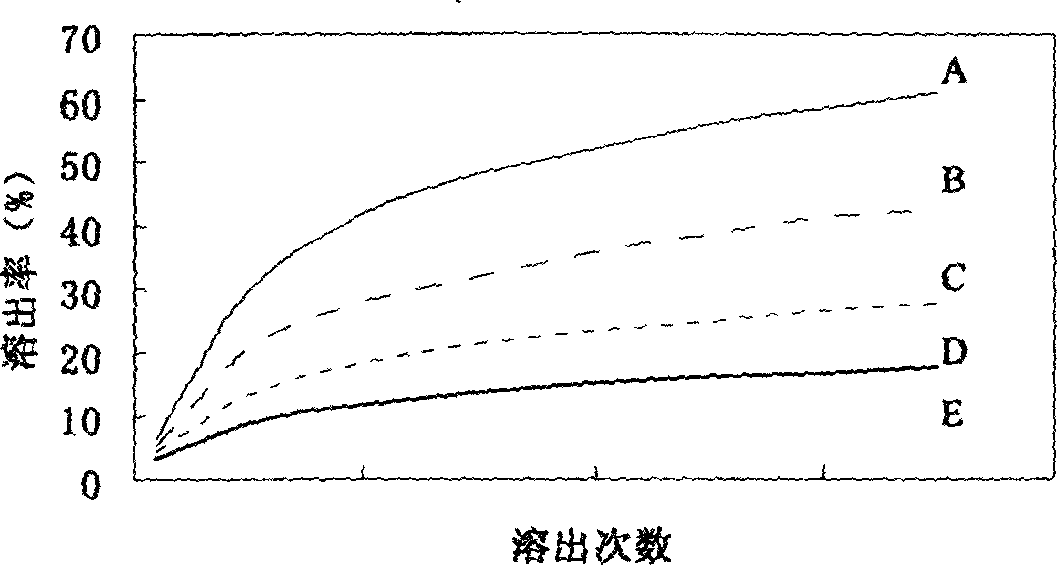

[0015] The method for preparing slow-release glass potash fertilizer by using smelting iron and steel waste slag, using smelting iron and steel waste slag as the main raw material, introducing a certain amount of potassium salt such as K 2 CO 3 , after melting into glass liquid, cool it slowly, and keep it warm at 900-1150°C to precipitate K in the glass 2 Ca 2 Si 2 o 7 Crystals, which can dissolve K in water. According to the design of chemical composition, the water solubility is between 1% and 3% depending on the holding temperature and holding time, and the remaining K 2 O can be slowly dissolved in citric acid secreted by plant roots.

[0016] Dissolve 1 g of the above-mentioned product with a particle size of 2 to 4 mm in 10 ml of 2% ammonium citrate solution for 15 minutes. After shaking, take out the clear liquid and analyze the K in the solution with an atomic absorption instrument. + content. After taking out the clarified liquid every time, replenish it to 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com