Red mud-silico-calcium-potash fertilizer and preparation method thereof

A technology of red mud and silicon-calcium, which is applied to potash fertilizers, calcium fertilizers, inorganic fertilizers, etc., can solve problems such as failure to achieve expected results and low effective silicon content, and save drying processes and costs, reduce production costs, and save The effect of cost expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

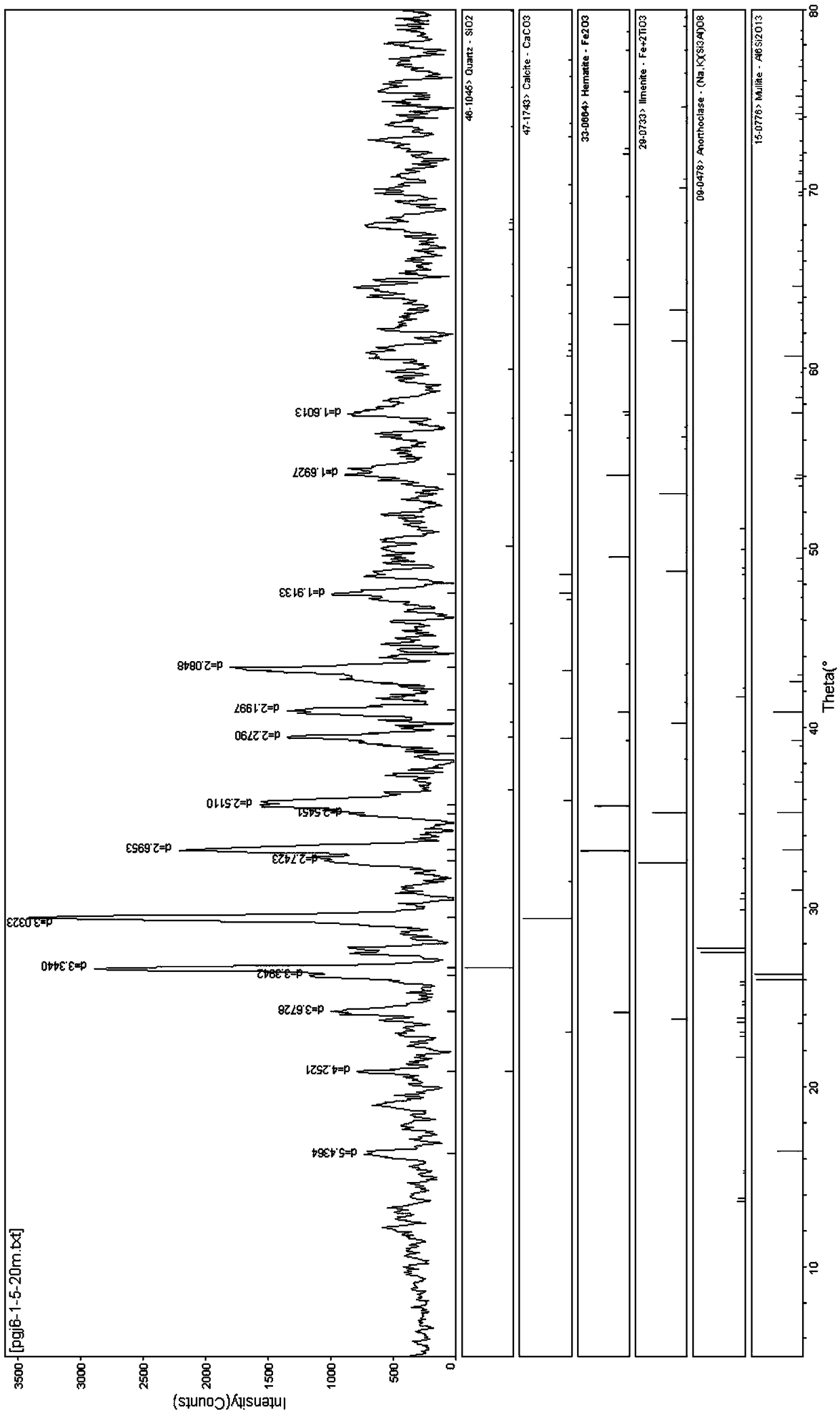

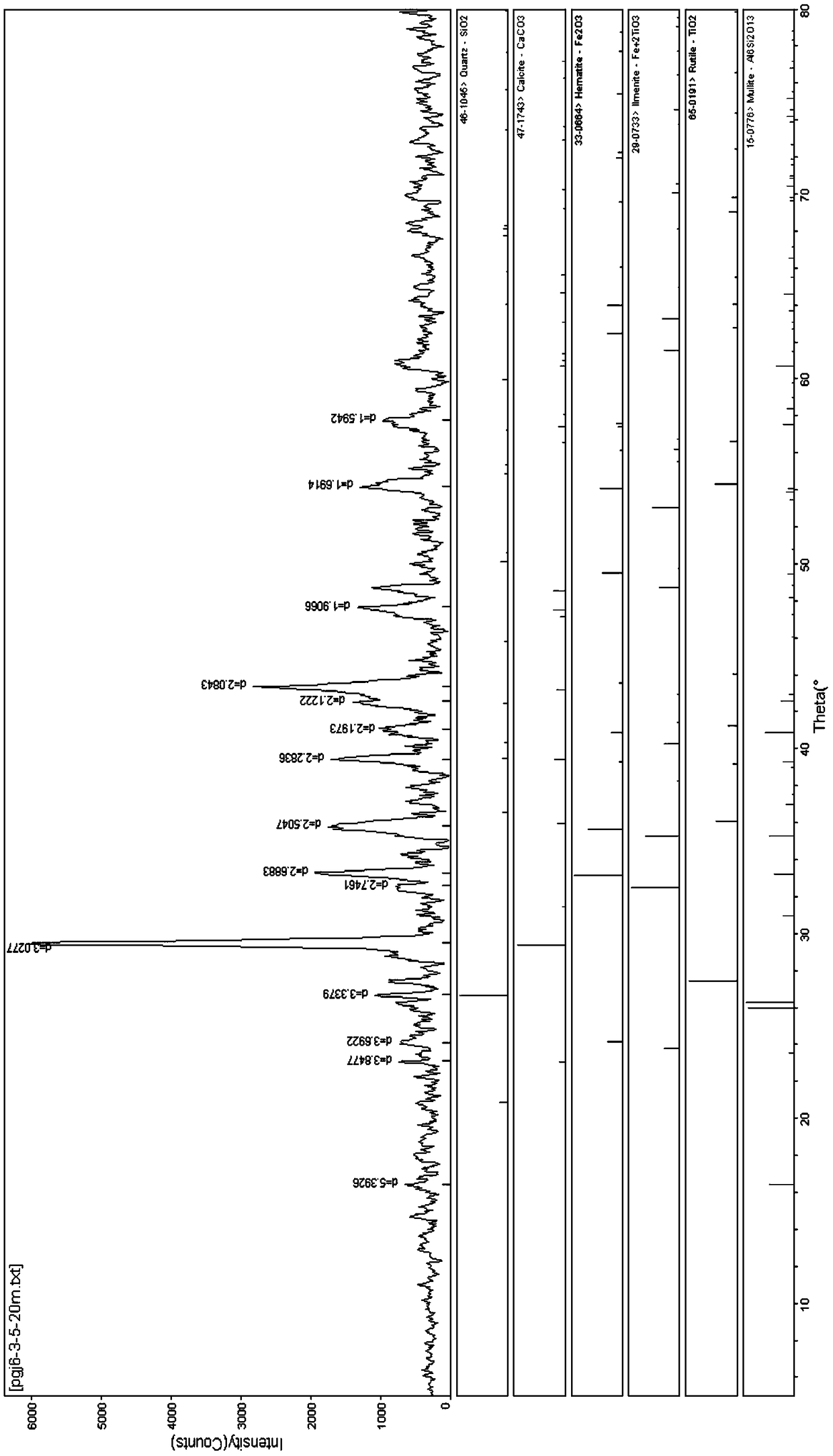

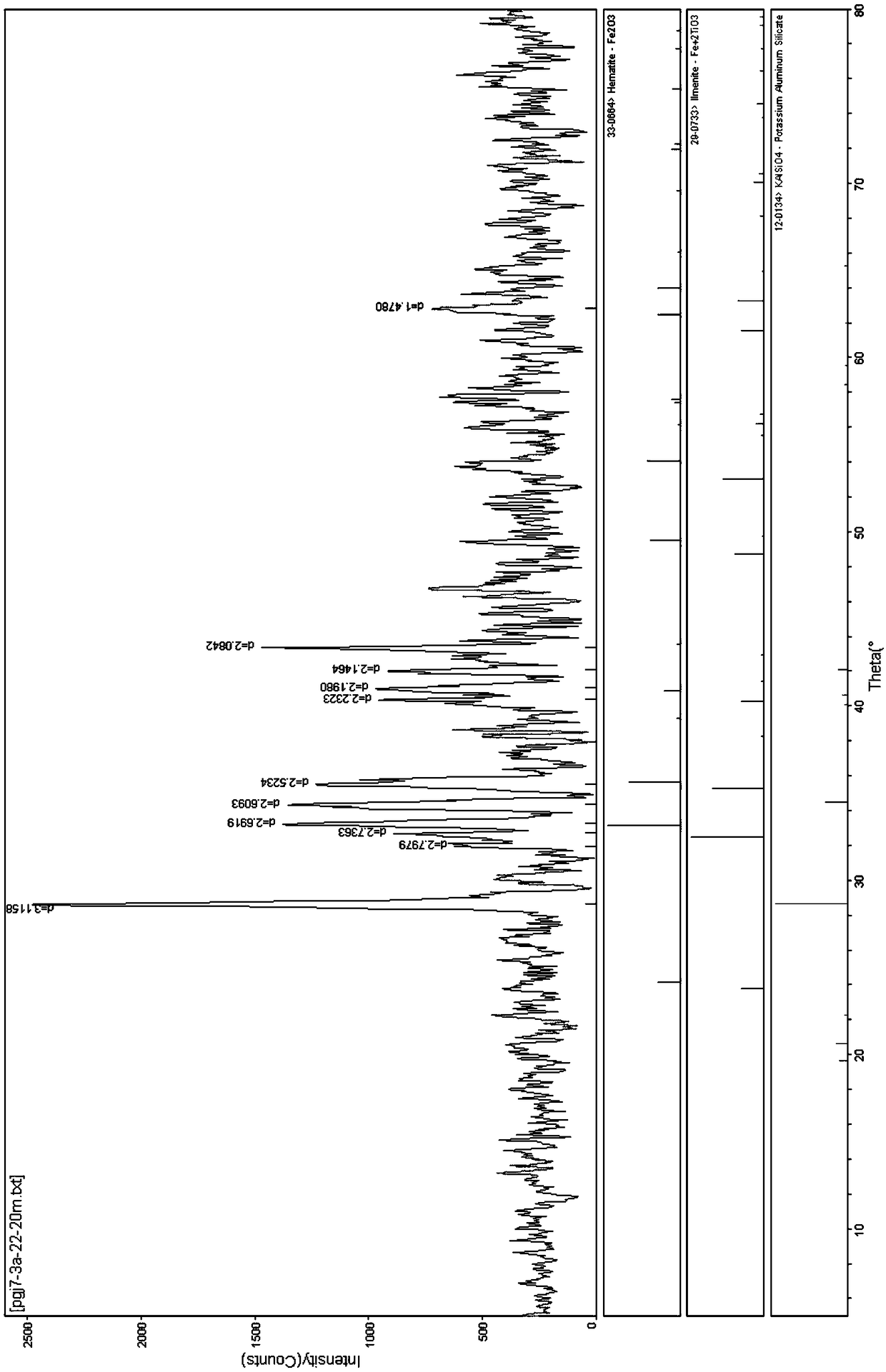

Image

Examples

Embodiment 1

[0042] 1) Weigh red mud, fly ash and desulfurization slag according to the mass percentage of 27%: 53%: 20%, and mix them uniformly to obtain a mixture;

[0043] 2) Take by weighing potassium hydroxide equivalent to 8% of the mass of the mixture, dissolve it in water equivalent to 20% of the quality of the mixture, add the potassium hydroxide solution to the mixture obtained in step 1), mix evenly, and carry out the Granulating (the grain that makes is cylindrical, and thickness is 3mm, and diameter is 1cm), obtains granular material;

[0044] 3) The obtained pellets are placed in dry powder ((composed of red mud, fly ash and desulfurization slag at a mass percentage of 27%: 53%: 20%)) to allow the pellets to fully contact with the dry powder, so that the surface of the pellets is wrapped with a Layer dry powder to obtain granules after powder makeup;

[0045] 4) The obtained powdered granular material is placed in a porcelain crucible and then roasted in a muffle furnace. Th...

Embodiment 2

[0050] 1) Weigh red mud, fly ash and desulfurization slag according to the mass percentage of 25%: 50%: 25%, and mix them uniformly to obtain a mixture;

[0051] 2) Take by weighing potassium hydroxide equivalent to 15% of the mass of the mixture, dissolve it in water equivalent to 20% of the quality of the mixture, add the potassium hydroxide solution to the mixture obtained in step 1), mix evenly, and carry out the Granulating (the grain that makes is cylindrical, and thickness is 3mm, and diameter is 1cm), obtains granular material;

[0052] 3) The obtained granules are placed in dry powder (fly ash) so that the granules are in full contact with the dry powder, so that the surface of the granules is coated with a layer of dry powder, and the powdered granules are obtained;

[0053] 4) The obtained powdered granular material is placed in a porcelain crucible and then roasted in a muffle furnace. The maximum furnace temperature is set to 600°C. After reaching 600°C, it is kep...

Embodiment 3

[0058] 1) Weigh red mud, fly ash and desulfurization slag according to the mass percentage of 25%: 50%: 25%, and mix them uniformly to obtain a mixture;

[0059] 2) Take by weighing potassium hydroxide equivalent to 20% of the mass of the mixture, dissolve it in water equivalent to 20% of the quality of the mixture, add the potassium hydroxide solution to the mixture obtained in step 1), mix evenly, and place the obtained material Carry out granulation in granulator (the granulation that makes is cylindrical, and thickness is 3mm, and diameter is 1cm), obtains granulate;

[0060] 3) The obtained granules are placed in dry powder (fly ash) so that the granules are in full contact with the dry powder, so that the surface of the granules is coated with a layer of dry powder, and the powdered granules are obtained;

[0061] 4) The powdered granular material obtained is placed in a porcelain crucible and then roasted in a muffle furnace. The maximum furnace temperature is set to 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com