Nitro-compound fertilizer and preparation method thereof

A technology of nitro compound fertilizer and potassium fertilizer, which is applied in the direction of phosphate fertilizer, fertilization device, fertilizer mixture, etc., can solve the problems of fertilization and storage difficulties, product nutrient loss, fertilizer agglomeration, etc., and achieve smooth particle shape, particle balance, and particle breaking little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

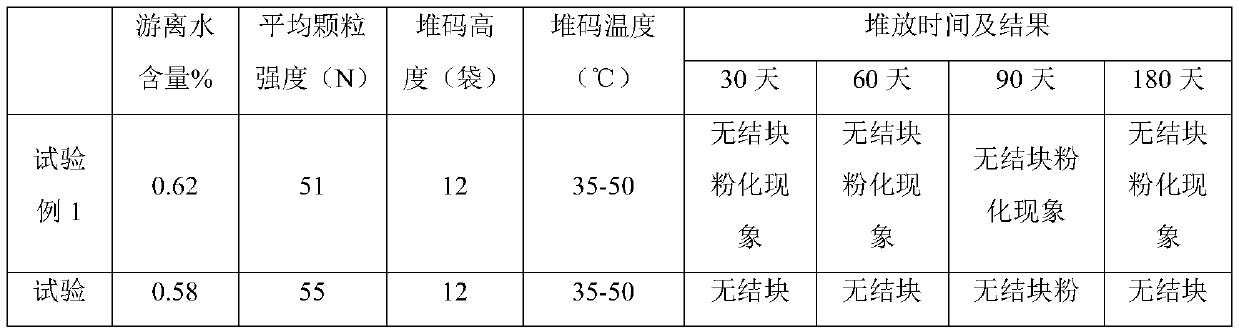

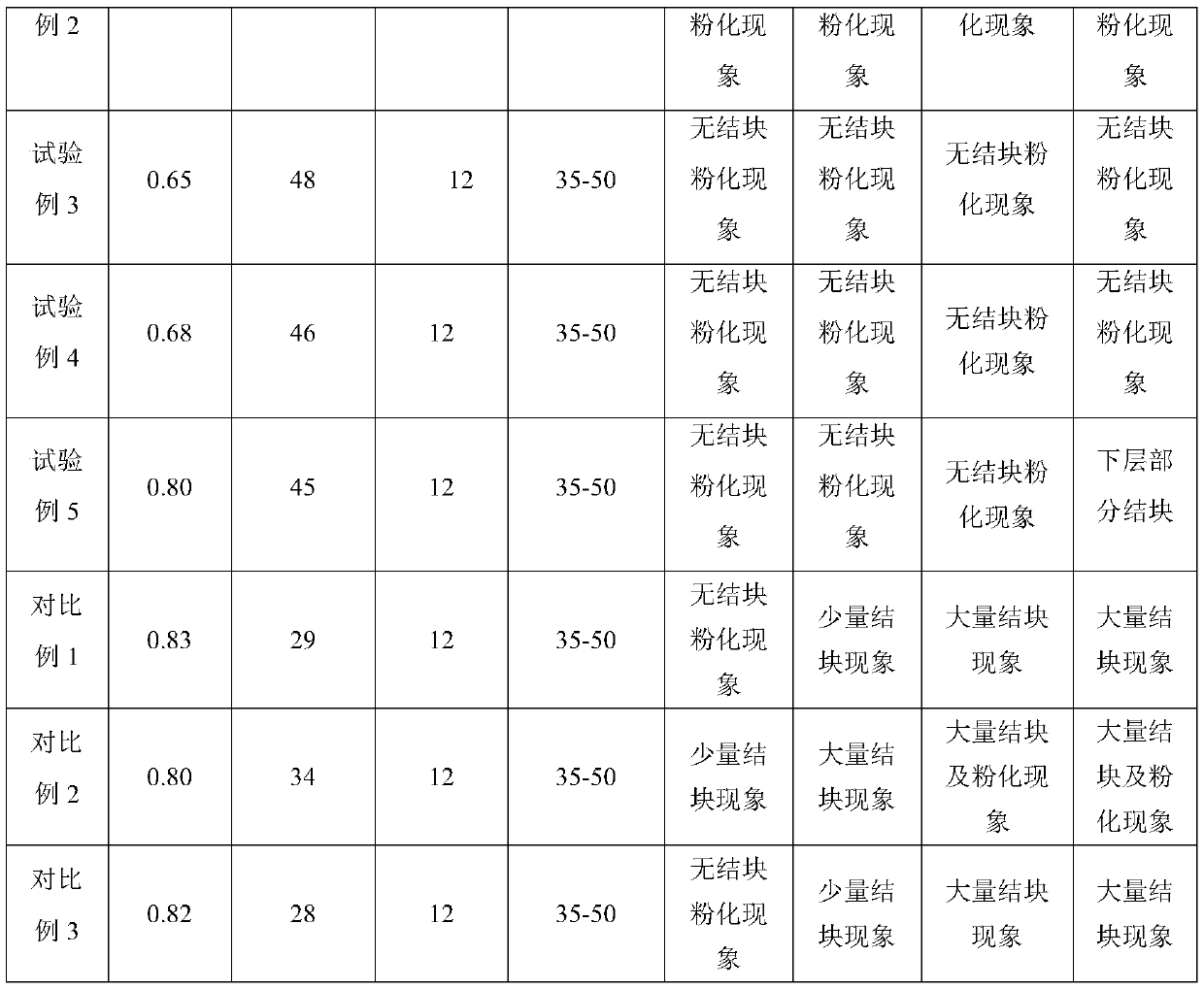

Examples

Embodiment 1

[0056] The embodiment of the present invention provides a kind of nitro compound fertilizer, and its raw material comprises the following components in parts by weight:

[0057] 30 parts of molten ammonium nitrate, 30 parts of monoammonium phosphate (phosphate fertilizer), 28 parts of potassium sulfate (potash fertilizer), 1 part of ammonium chloride (fertilizer stabilizer) and 1 part of magnesium oxide (fertilizer stabilizer).

[0058] The nitro compound fertilizer is prepared by using the above-mentioned raw materials, and the specific steps of the preparation method are as follows.

[0059] Add 30 parts of molten ammonium nitrate at 170°C from the ammonium nitrate system into continuous reactor A, keep the temperature at 160°C, and stir for 5 minutes;

[0060] Add 28 parts of potassium sulfate into continuous reactor A, keep the temperature at 160°C, and stir for 5 minutes;

[0061] overflowing the mixture in continuous reactor A to continuous reactor B;

[0062] Add 30 par...

Embodiment 2

[0065] The embodiment of the present invention provides a kind of nitro compound fertilizer, and its raw material comprises the following components in parts by weight: 41.5 parts of molten ammonium nitrate, 8 parts of monoammonium phosphate (phosphate fertilizer), 48 parts of potassium sulfate (potassium fertilizer), 1.5 parts of ammonium chloride (fertilizer stabilizer) and 1 part magnesium oxide (fertilizer stabilizer).

[0066] The nitro compound fertilizer is prepared by using the above-mentioned raw materials, and the specific steps of the preparation method are as follows.

[0067] Add 41.5 parts of molten ammonium nitrate at 175°C from the ammonium nitrate system into continuous reactor A, keep the temperature at 165°C, and stir for 5 minutes; add 24 parts of potassium sulfate into continuous reactor A, keep the temperature at 165°C, and stir for 10 minutes;

[0068] Then, overflow the mixture in the continuous reactor A into the continuous reactor B, and add 8 parts o...

Embodiment 3

[0071] The embodiment of the present invention provides a kind of nitro compound fertilizer, and its raw material comprises the following components in parts by weight: 62 parts of molten ammonium nitrate, 19 parts of monoammonium phosphate (phosphate fertilizer), 0.5 part of ammonium sulfate (solid nitrogen fertilizer), 15.5 parts 1 part potassium sulfate (potash fertilizer), 1.5 parts ammonium chloride (fertilizer stabilizer) and 1.5 parts magnesium oxide (fertilizer stabilizer).

[0072] The nitro compound fertilizer is prepared by using the above-mentioned raw materials, and the specific steps of the preparation method are as follows.

[0073] Add 62 parts of molten ammonium nitrate at 165°C from the ammonium nitrate system into continuous reactor A, keep the temperature at 160°C, and stir for 10 minutes; add 0.5 parts of ammonium sulfate and 10 parts of potassium sulfate into continuous reactor A, and keep the temperature at 160°C °C, stir for 10 minutes;

[0074] Then, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com