Potash fertilizer with high water retention capacity

A technology of potassium fertilizer and high performance, applied in the field of new fertilizers, can solve the problems of unfavorable crop growth and other problems, and achieve the effect of convenient and simple use and strong water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) super magnesium carbonate and potassium sulfate are dropped into respectively in two feed bins and put in materials by controlling metering scales, super magnesium carbonate is Uppsa salt, and 1 gram of surface area reaches 800 square meters, wherein super magnesium carbonate 5%, sulfuric acid Potassium 94.5%, put into the ball mill and carry out mixing and grinding for 30min;

[0021] (2) The mixed material is conveyed in the granulation drum by the belt, and 0.5% urea is mixed with mass concentration and is that 10% urea solution is sprayed to the potassium sulfate fertilizer surface through the nozzle to make potassium sulfate form particles;

[0022] (3) Send the granulated potassium sulfate into the drying drum for drying, and then sieve and pack the fertilizer after drying.

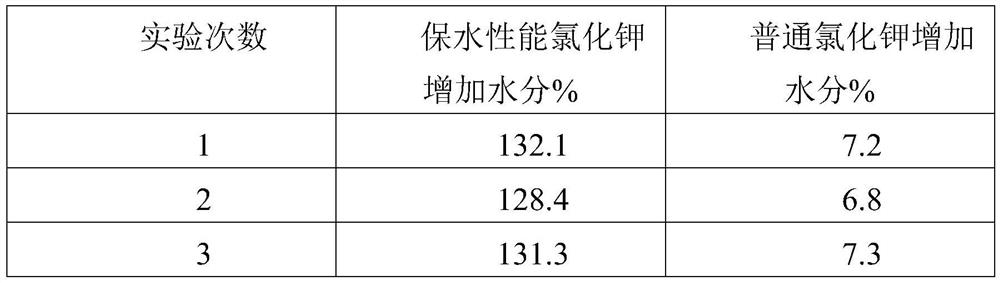

[0023] After drying 100g fertilizer at 104°C, bury it in one kilogram of soil for two hours, dry the used soil at 180°C for 2 hours, and then add 300ml of water.

[0024]

[0025] It ...

Embodiment 2

[0027] (1) super magnesium carbonate and potassium chloride are dropped into respectively in two feed bins and put in material by controlling metering scale, super magnesium carbonate is Uppsa salt, and 1 gram of surface area reaches 800 square meters, wherein super magnesium carbonate 1%, Potassium chloride 98.9%, put into the ball mill and carry out mixing and grinding for 30min;

[0028] (2) The mixed material is conveyed to the granulation drum by a belt, and the 0.1% modified starch is mixed with a mass concentration of 5% modified starch solution, which is sprayed onto the surface of the potassium chloride fertilizer through a nozzle to form potassium chloride into granules;

[0029] (3) Send the granulated potassium chloride into the drying drum for drying, and then sieve and pack the fertilizer after drying.

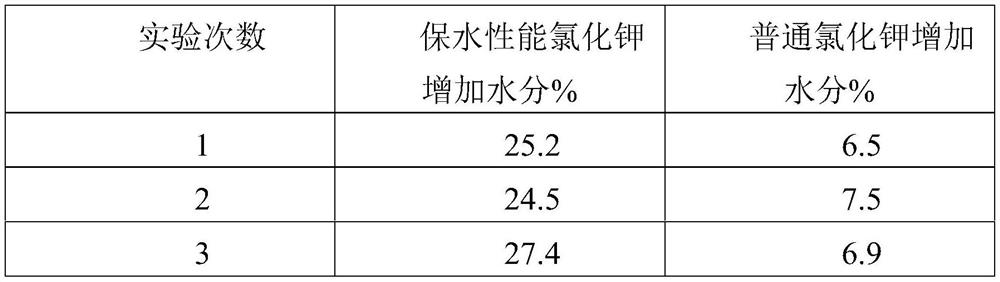

[0030] After drying 100g fertilizer at 104°C, bury it in one kilogram of soil for two hours, dry the used soil at 180°C for 2 hours, and then add 300ml of water....

Embodiment 3

[0034] (1) Put the modified kaolin and potassium chloride into two silos respectively and put in the materials by controlling the metering scale, wherein 8% of the modified kaolin and 90% of the potassium chloride are used, and the modified kaolin and the potassium chloride are mixed with 0.8 : The ratio of 9.2 is put into the ball mill and carried out mixing and grinding for 20min;

[0035] (2) The mixed material is conveyed in the granulation drum by a belt, and 2% polyvinyl alcohol is mixed with a mass concentration of 1% polyvinyl alcohol solution and sprayed onto the potassium chloride fertilizer surface through a nozzle to form potassium chloride into particles;

[0036] (3) Send the granulated potassium chloride into the drying drum for drying, and then sieve and pack the fertilizer after drying.

[0037] After drying 100g fertilizer at 104°C, bury it in one kilogram of soil for two hours, dry the used soil at 180°C for 2 hours, and then add 300ml of water.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com