Rubber fastener for automobile air conditioner pipe and manufacturing method of rubber fastener

A technology for rubber fasteners and automobile air conditioners is applied in the field of rubber fasteners for automobile air conditioner pipes and their preparation, and can solve the problems of cracking of the fasteners, affecting the service life of products, breaking and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] A kind of preparation method of rubber fastener for automobile air-conditioning pipe, wherein, described preparation method is:

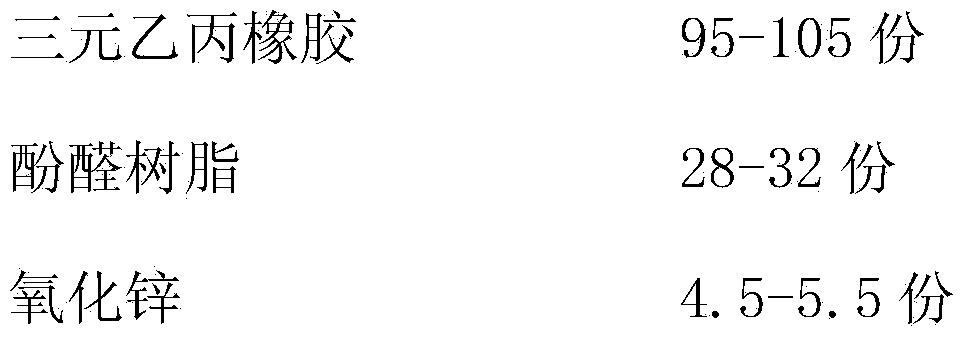

[0034] 1. Preparation of raw materials for fastener body

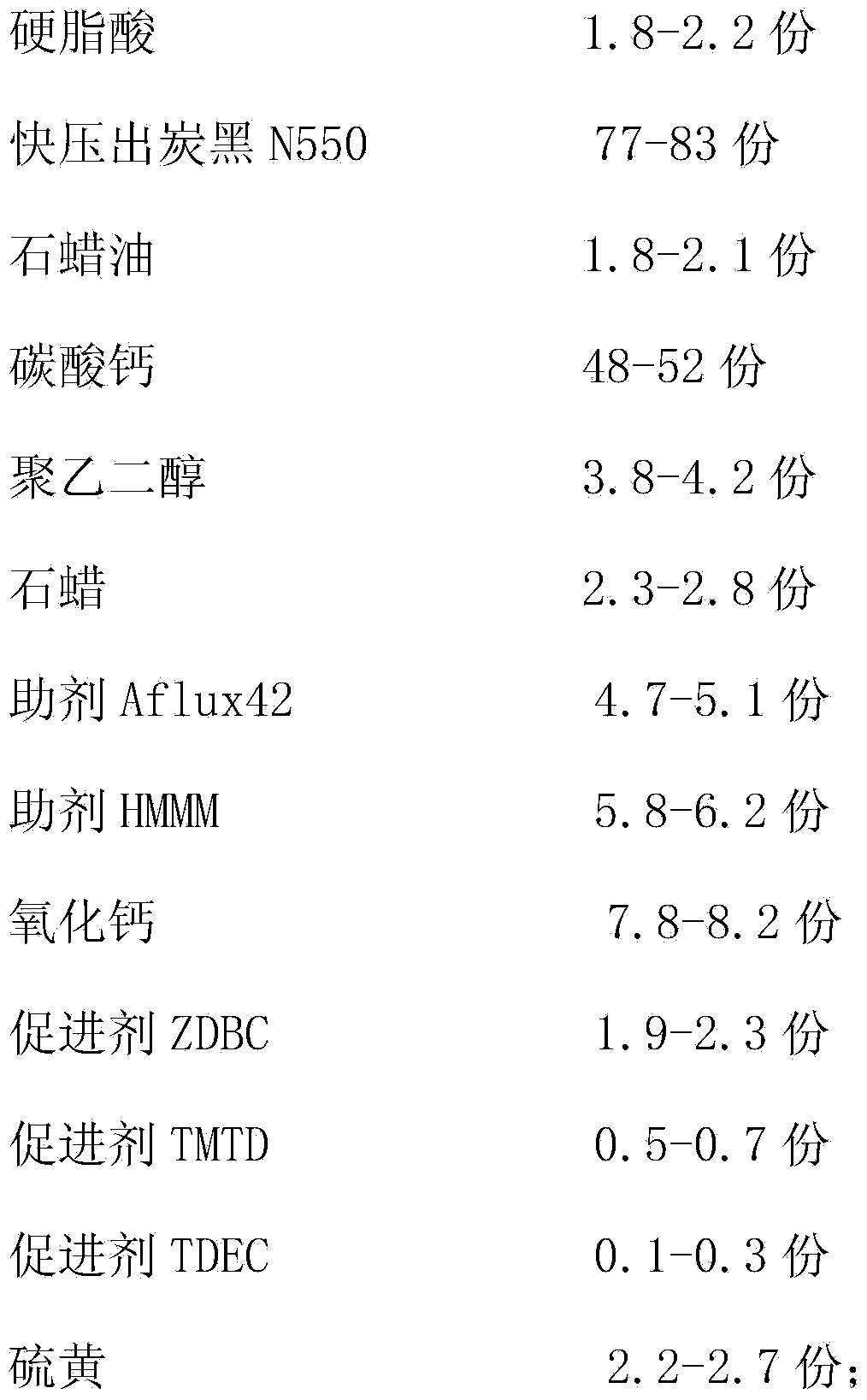

[0035] (1) 100 parts by weight of EPDM rubber, 30 parts of phenolic resin, 5 parts of zinc oxide, 2 parts of stearic acid, 80 parts of fast extruded carbon black N55080 parts, 2 parts of paraffin oil, and 50 parts of calcium carbonate , 4 parts of polyethylene glycol, 2.5 parts of paraffin, 425 parts of auxiliary agent Aflux, 6 parts of auxiliary agent HMMM, and 8 parts of calcium oxide were added to the kneader and stirred at a constant speed to obtain primary raw material 1. The stirring temperature was 145 ° C and the time was 30 minutes;

[0036] (2) Add primary raw material 1, 2 parts of accelerator ZDBC, 0.6 parts of accelerator TMTD, 0.2 parts of accelerator TDEC, and 2.5 parts of sulfur into the open mill for mixing at room temperature to obtain raw material semi-finished prod...

example 2

[0042] A kind of preparation method of rubber fastener for automobile air-conditioning pipe, wherein, described preparation method is:

[0043] 1. Preparation of raw materials for fastener body

[0044] (1) 100 parts by weight of EPDM rubber, 31 parts of phenolic resin, 4.8 parts of zinc oxide, 1.9 parts of stearic acid, 78 parts of quick-extruded carbon black N55078 parts, 1.9 parts of paraffin oil, and 51 parts of calcium carbonate , 4.1 parts of polyethylene glycol, 2.6 parts of paraffin, 24.8 parts of auxiliary agent Aflux4, 6 parts of auxiliary agent HMMM, and 8.1 parts of calcium oxide were added to the kneader and stirred at a constant speed to obtain primary raw material 1. The stirring temperature was 145 ° C and the time was 30 minutes. ;

[0045] (2) Add primary raw material 1, 2.2 parts of accelerator ZDBC, 0.6 parts of accelerator TMTD, 0.1 part of accelerator TDEC, and 2.3 parts of sulfur into the open mill for mixing at room temperature to obtain raw material s...

example 3

[0051] A kind of preparation method of rubber fastener for automobile air-conditioning pipe, wherein, described preparation method is:

[0052] 1. Preparation of raw materials for fastener body

[0053](1) 98 parts by weight of EPDM rubber, 28 parts of phenolic resin, 4.6 parts of zinc oxide, 2.1 parts of stearic acid, 2.1 parts of paraffin oil, 48 parts of calcium carbonate , 3.8 parts of polyethylene glycol, 2.4 parts of paraffin, 25.1 parts of auxiliary agent Aflux4, 6.2 parts of auxiliary agent HMMM, and 7.8 parts of calcium oxide were added to the kneader and stirred at a constant speed to obtain primary raw material 1. The stirring temperature was 145 ° C, and the time 30min;

[0054] (2) Add primary raw material 1, 1.9 parts of accelerator ZDBC, 0.7 parts of accelerator TMTD, 0.3 parts of accelerator TDEC, and 2.6 parts of sulfur into the open mill for mixing at room temperature to obtain raw material semi-finished product 1;

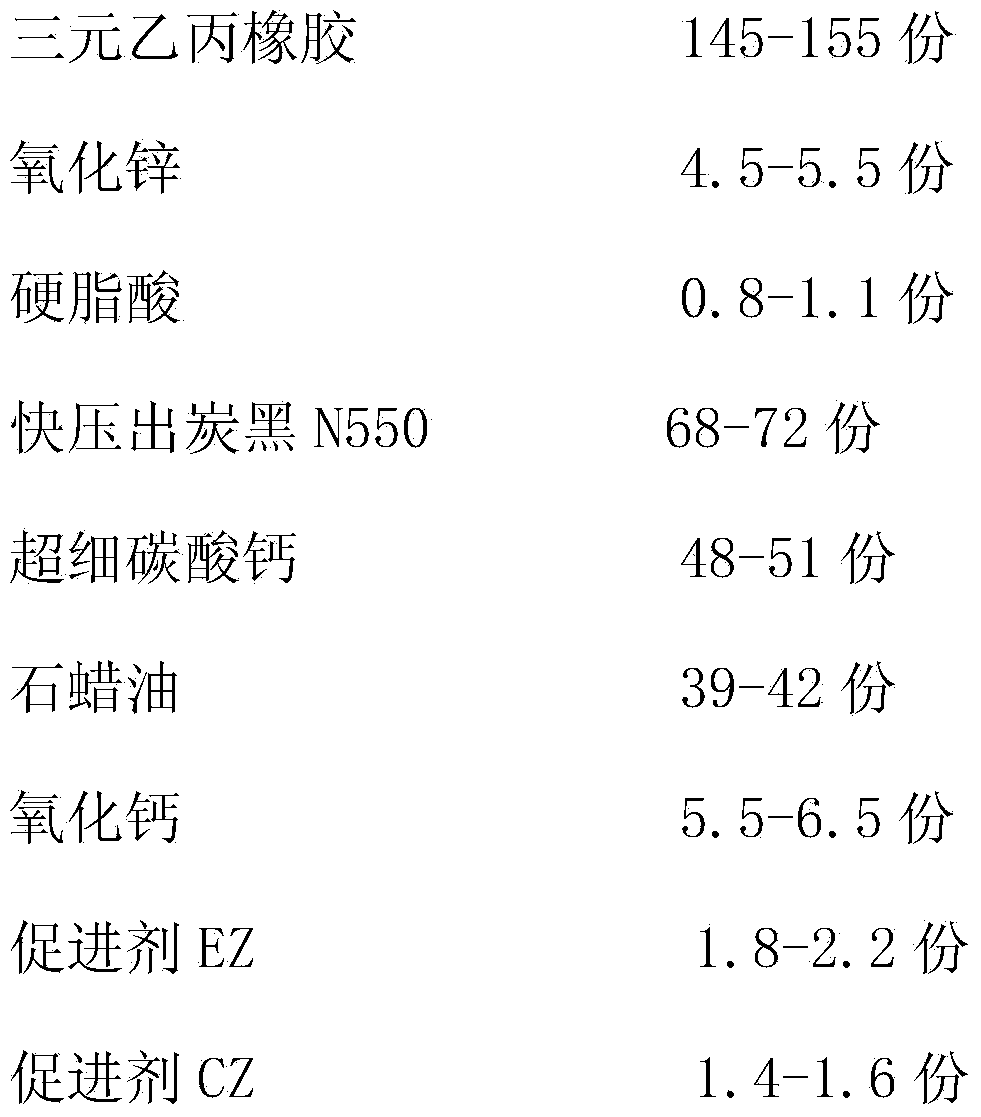

[0055] 2. Preparation of raw materials f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com