Method for improving vulcanization characteristics of ethylene propylene diene monomer by composite lignin

A technology of EPDM rubber and vulcanization characteristics, applied in the field of rubber materials, can solve the problems of general performance of vulcanized EPDM rubber, unable to meet the needs of the market, and general vulcanization characteristics, so as to shorten the vulcanization induction period and improve the vulcanization. characteristics, the effect of increasing the vulcanization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

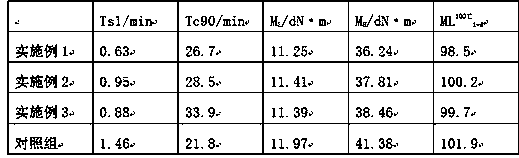

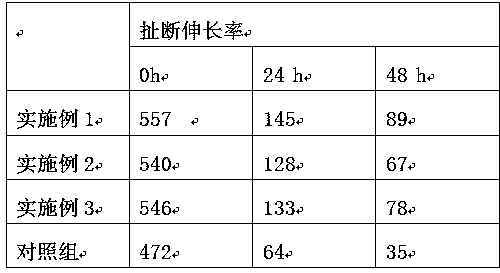

Examples

Embodiment 1

[0015] A method for compounding lignin to improve the vulcanization characteristics of EPDM rubber, comprising the following steps:

[0016] S1 Add EPDM rubber to the mixer for mixing treatment, then add carbon black, carbon free radical scavenger, stearic acid, after mixing evenly, the mixing time is 8min, and discharge , to obtain rubber compound; wherein, the mass ratio of carbon black and carbon free radical scavenger is 50:1, and the order of adding carbon black and carbon free radical scavenger is to add carbon black first, then cross 5min, then add carbon free radical Capture agent, described carbon black is N550 carbon black, described EPDM rubber and carbon black, stearic acid mixing mass ratio are 100:65:0.3, and DCPD content is 5% in described EPDM rubber;

[0017] Wherein, the carbon free radical scavenger is a hydroxylamine carbon free radical scavenger.

[0018] S2 Add the mixed rubber obtained in step S1 to the open mill, and then add accelerator, vulcanizing a...

Embodiment 2

[0023] A method for compounding lignin to improve the vulcanization characteristics of EPDM rubber, comprising the following steps:

[0024] S1 Add EPDM rubber to the mixer for mixing treatment, then add carbon black, carbon free radical scavenger, stearic acid, after mixing evenly, the mixing time is 10min, and discharge , to obtain rubber compound; wherein, the mass ratio of carbon black and carbon free radical scavenger is 55:1, and the order of adding carbon black and carbon free radical scavenger is to add carbon black first, then cross 6min, then add carbon free radical Capture agent, described carbon black is N550 carbon black, described EPDM rubber and carbon black, stearic acid mixing mass ratio are 100:65:0.5, and DCPD content is 6% in the described EPDM rubber;

[0025] Wherein, the carbon free radical scavenger is a hydroxylamine carbon free radical scavenger.

[0026] S2 Add the mixed rubber obtained in step S1 to the open mill, then add accelerator, vulcanizing ...

Embodiment 3

[0031] A method for compounding lignin to improve the vulcanization characteristics of EPDM rubber, comprising the following steps:

[0032] S1 Add EPDM rubber into the mixer for mixing treatment, then add carbon black, carbon free radical scavenger, stearic acid, after mixing evenly, the mixing time is 9min, and discharge , to obtain rubber compound; wherein, the mass ratio of carbon black and carbon free radical scavenger is 52:1, and the order of adding carbon black and carbon free radical scavenger is to add carbon black first, then cross 5.5min, then add carbon free radical Base capture agent, described carbon black is N550 carbon black, described EPDM rubber and carbon black, stearic acid mixing mass ratio are 100:65:0.4, and DCPD content is 5.5% in described EPDM rubber ;

[0033] Wherein, the carbon free radical scavenger is a hydroxylamine carbon free radical scavenger.

[0034] S2 Add the mixed rubber obtained in step S1 to the open mill, then add accelerator, vulc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com