Composite cutter disc of food rubbish processor

A technology for food waste treatment and compound knife, which is applied in grain treatment, indoor sanitary piping device, water supply device, etc., can solve the problems of multi-social labor, unsanitary and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

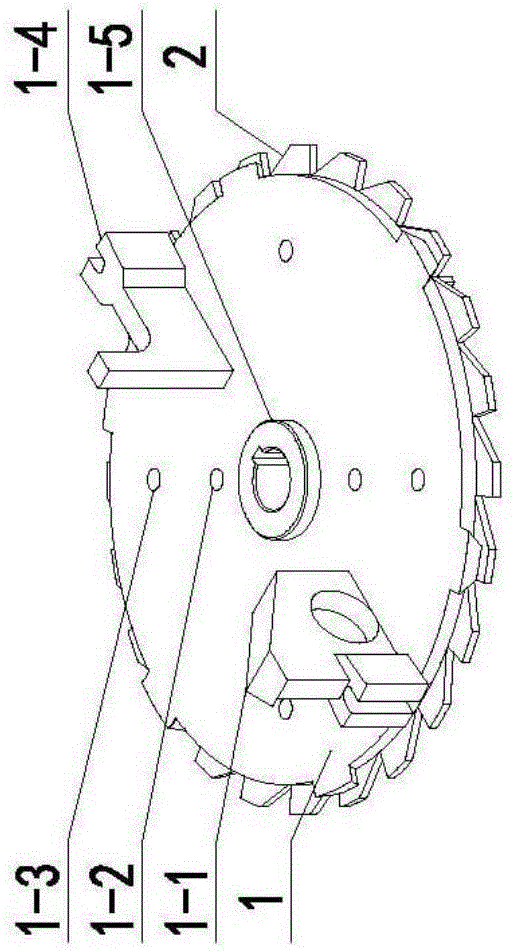

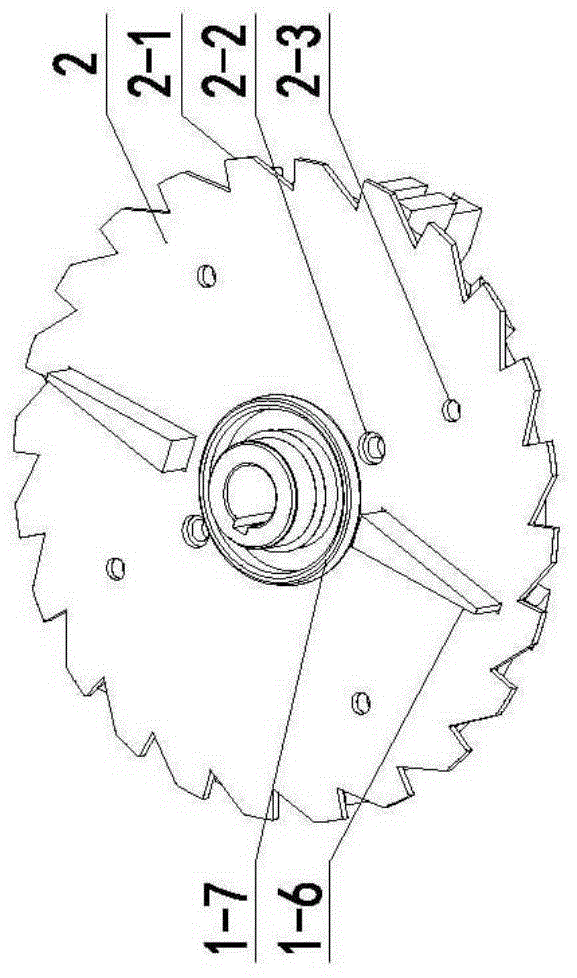

[0016] The compound cutter head of the food waste disposer is characterized in that the second cutter head 2 is fixed under the first cutter head 1 by bolts:

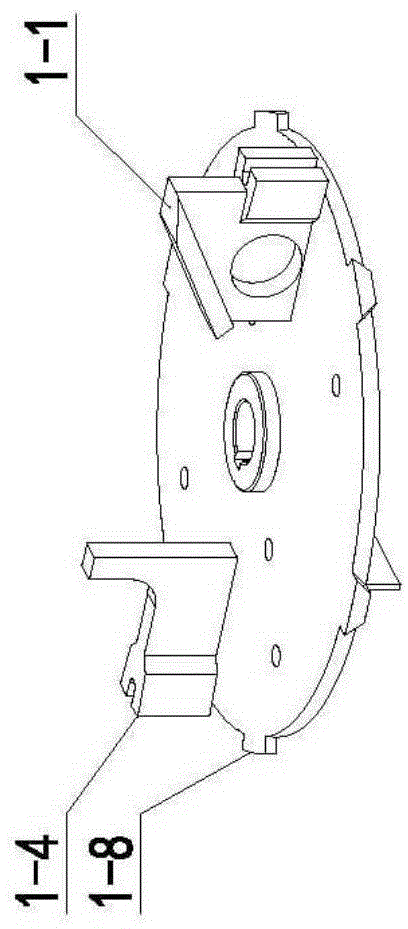

[0017] The first cutter head 1 is in the shape of a disc, and at least there are a first cutter block 1-1 and a second cutter block 1-4 on the top, a third cutter block 1-8 on the peripheral wall and a first cutter block 1-8 on the bottom. Four knife blocks 1-6, and craft holes;

[0018] The first knife block 1-1 is a combination of a fork-shaped block and an integral knife head made above it. The fork tip is located on the edge of the disc, the fork rod points to the center of the circle and has an extrusion hole, the knife head is inclined to the axis, and the blade and the motor The direction of rotation is the same, and the rotation trajectory of the blade is funnel-shaped; the second knife block 1-4 on the opposite side is also a fork-shaped block and an integrated knife rod assembly, and the knife rod stands uprig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com