Intelligent and efficient noodle making method of noodle maker, and noodle maker

A noodle machine, an intelligent technology, applied in the directions of dough mixers, dough extruders, and structural components of mixing/kneading machines, etc., can solve the problems of difficult cleaning of dough residues, affecting the machine's output rate, and affecting user experience, etc. The effect of reducing dough residue, less residue and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

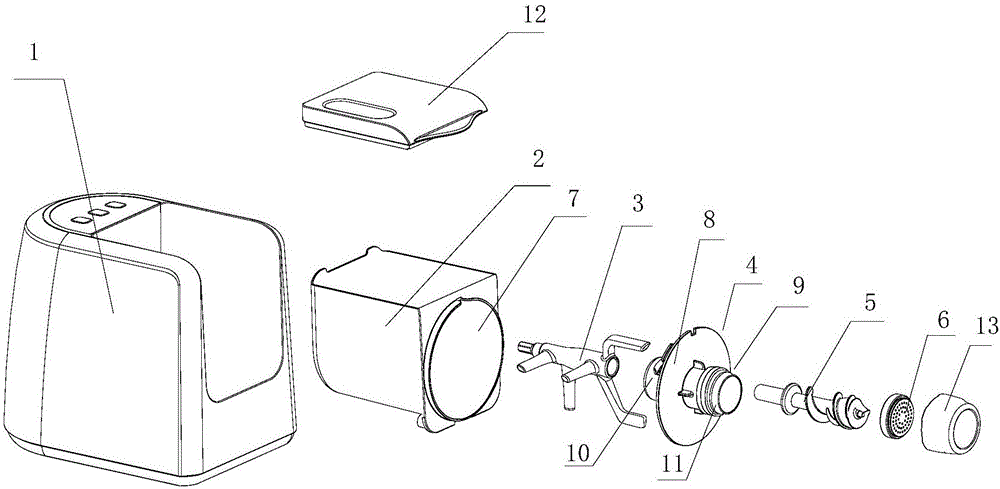

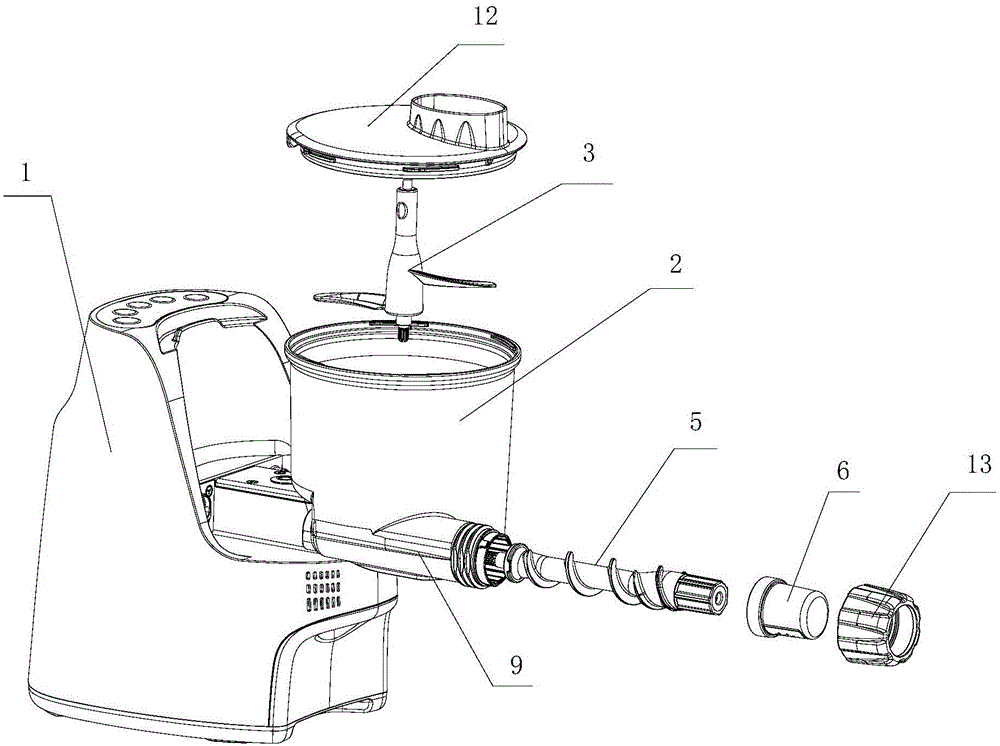

[0042] Such as Figure 1 to Figure 5 Shown, the noodle making method of noodle machine of the present invention comprises the following steps:

[0043] (1) Kneading steps:

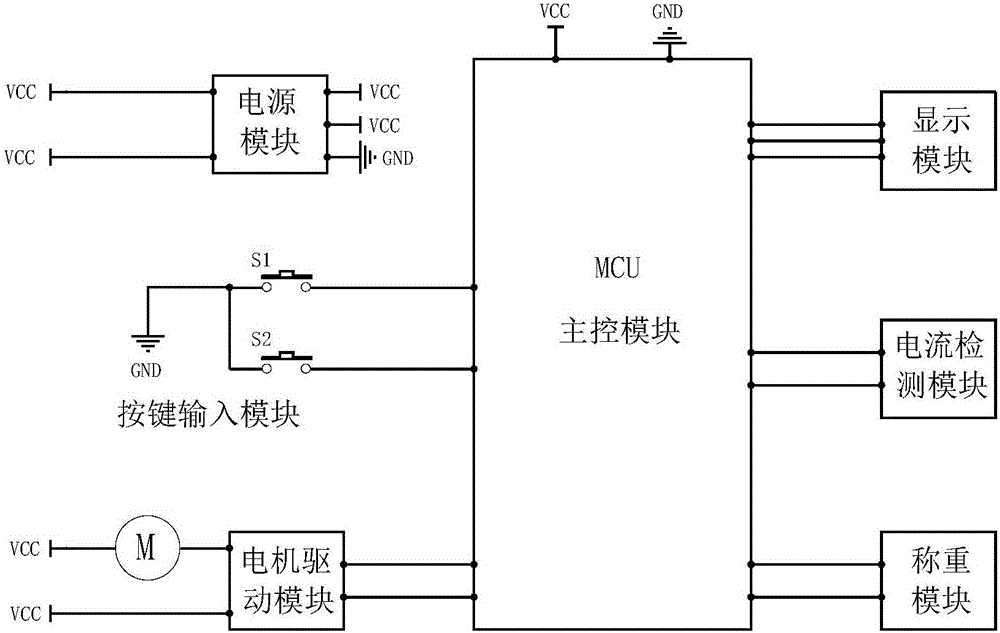

[0044] Put an appropriate amount of flour and water through the weighing module, and then start the machine through the key input module, the power module is powered on, the MCU main control module outputs a signal to the motor drive module, the motor drives the stirring rod 3 and the screw 5 to rotate in reverse, and the stirring rod 3 stirs Stir the flour and water in the cup 2 to make the flour and water mix into dough, and the dough that is brought into the extruding cylinder 4 by the rotation of the stirring rod 3 is brought into the stirring cup 2 with the rotation of the screw 5, and is mixed with the stirring cup The dough in 2 is remixed, and this step lasts for 3 minutes. When this step is carried out, the display module displays the remaining time synchronously.

[0045] (2) Waking up steps: ...

Embodiment 2

[0062] The difference between the noodle making method of this embodiment and the first embodiment is that the working state of the screw is different during the intermittent noodle extrusion process in the extrusion molding step.

[0063] Such as Image 6 As shown, the intermittent dough extrusion process is set within the first 3 minutes of the extrusion molding step, and in the intermittent dough extrusion process, the screw 5 first continuously extrudes the dough at a higher speed A for T seconds, Stop for S seconds, and the screw 5 will continue to extrude the face at a lower speed B for T seconds, and stop for S seconds, wherein the value range of T is 30 seconds to 60 seconds, preferably 30 seconds, and the value of S The range is 3 seconds to 10 seconds, preferably 5 seconds, the value range of the speed A is 55r / min to 80r / min, A is preferably 60r / min, and the value range of the speed B is 30r / min to 50r / min, B is preferably 40r / min, and A is greater than B. The adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com