Silicone master batch with high silicone content and preparation method of silicone master batch

A technology of high silicone content and silicone masterbatch, which is applied in the field of polymer materials, can solve the problems of low silicone content and complicated preparation process, and achieve the effects of high production efficiency, simple process and basic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

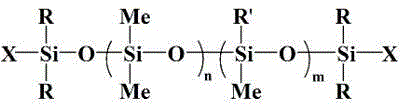

Method used

Image

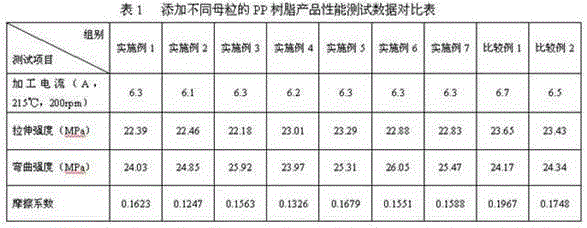

Examples

Embodiment 1

[0037] A silicone masterbatch with high silicone content, the weight ratio of raw materials is as follows:

[0038] Silicone 50%

[0039] Carrier resin 39.5%

[0040] Compatibilizer 10%

[0041] Auxiliary 0.5%

[0042] The silicone is methyl silicone oil with a number average molecular weight of 1 million;

[0043] The carrier resin is low-density polyethylene (LDPE), 2426K;

[0044] The compatibilizer is hydrogenated styrene-butadiene block copolymer (SEBS), Baling Petrochemical YH 501;

[0045] The auxiliary agent is antioxidant B245.

[0046] First weigh the carrier resin, compatibilizer, and additives and mix them in a mixer with a rotation speed of 400-600rpm for 5 minutes; then pass the mixed materials together with the weighed silicone through a twin-screw extruder at 120 Extrude and granulate at -160°C with a rotational speed of 200-300 rpm to obtain a silicone masterbatch.

Embodiment 2

[0048] A silicone masterbatch with high silicone content, the weight ratio of raw materials is as follows:

[0049] Silicone 65%

[0050] Carrier resin 19.2%

[0051] Compatibilizer 15%

[0052] Auxiliary 0.8%

[0053] The silicone is a methyl vinyl silicone rubber with a molecular weight of 700,000;

[0054] The carrier resin is homopolypropylene (PP), T30S;

[0055] The compatibilizer is styrene-butadiene block copolymer (SBS), Baling Petrochemical YH-791;

[0056] Described auxiliary agent is antioxidant B245 and ultraviolet absorber UV-P;

[0057] First weigh the carrier resin, compatibilizer and additives and mix them in a mixer with a rotation speed of 600-800rpm for 5 minutes; then pass the mixed materials together with the weighed silicone through the twin-screw extruder at 190 Extrude and granulate at -240°C with a rotational speed of 200-300 rpm to obtain a silicone masterbatch.

Embodiment 3

[0059] A silicone masterbatch with high silicone content, the weight ratio of raw materials is as follows:

[0060] Silicone 55%

[0061] Carrier resin 29.7%

[0062] Compatibilizer 15%

[0063] Auxiliary 0.3%

[0064] Described silicone is the methyl silicone oil that molecular weight is 750,000;

[0065] The carrier resin is homopolymerized high-impact polystyrene (HIPS), Taiwan Chimei PH88;

[0066] Described auxiliary agent is antioxidant AT10 and ultraviolet absorber UV-P;

[0067] The compatibilizer is styrene-butadiene block copolymer (SBS), Baling Petrochemical YH-802.

[0068] First weigh the carrier resin, compatibilizer, and additives and mix them in a mixer with a rotation speed of 800-1000rpm for 5 minutes; then pass the mixed materials together with the weighed silicone through a twin-screw extruder at 200 Extrude and granulate at -240°C with a rotational speed of 200-300 rpm to obtain a silicone masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com