Efficient plasticizing single-screw extruder

A single-screw extruder, high-efficiency technology, applied in the field of high-efficiency plasticizing single-screw extruder, can solve the problems of solid conveying efficiency, melting efficiency, melt mixing and conveying efficiency, etc., to achieve improved mixing capacity and energy-saving extrusion Forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

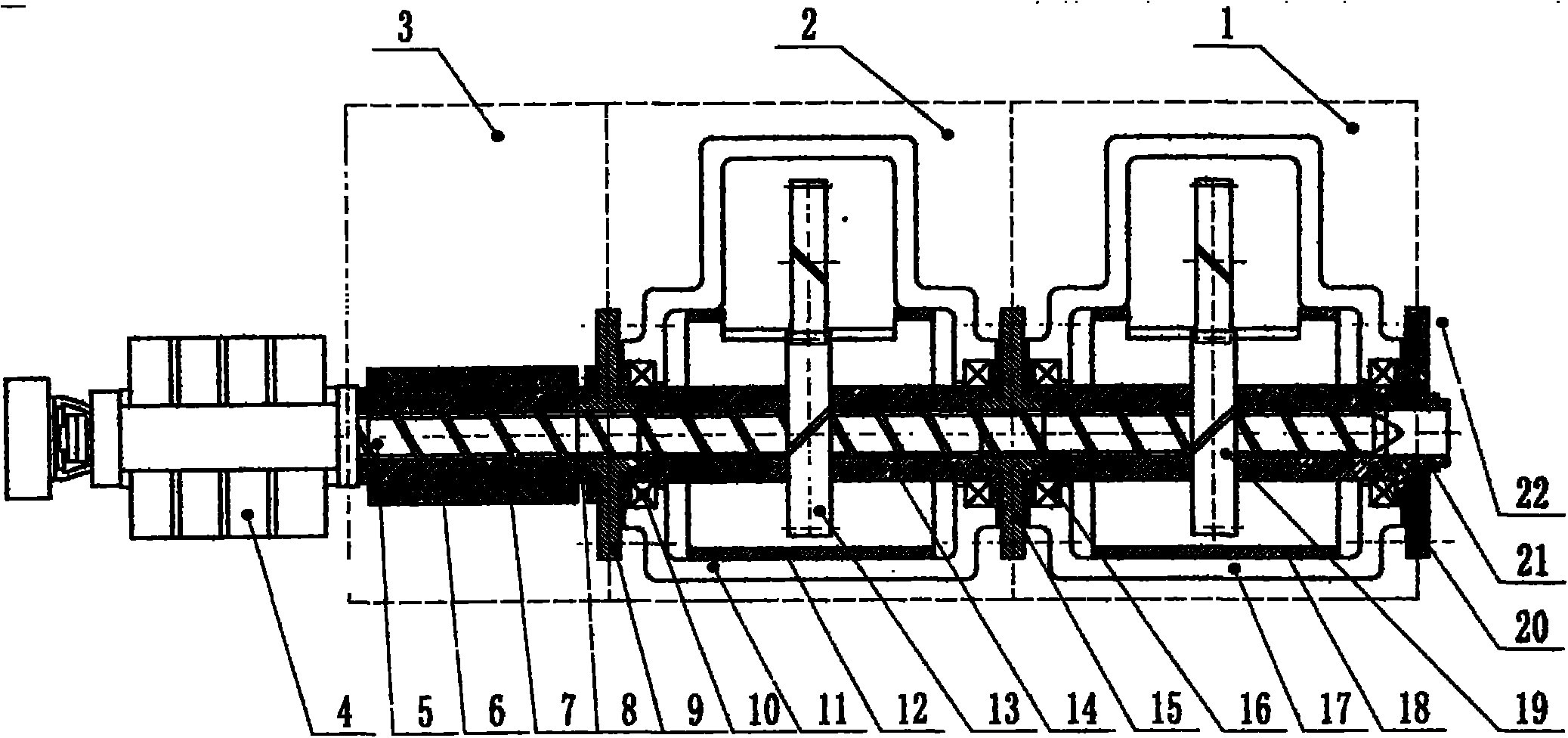

Image

Examples

no. 1 example

[0021] The first embodiment: a high-efficiency plasticizing extruder with a nominal diameter of 90 mm and an aspect ratio of 30. Among them, the barrel of the circular body conveying section is a grooved barrel, the aspect ratio is 8, the groove depth is 4mm, the groove width is 8mm, the number of groove heads is 8, and the groove lead is 90mm; The barrel is a smooth barrel with a length-to-diameter ratio of 15; the barrel in the melt conveying section is a pin barrel with a length-to-diameter ratio of 7. The screw is a conventional screw with a lead of 45mm, the number of screw threads is 1, and the normal phase width of the screw edge is 4.5mm; the groove depth of the solid conveying section is 3mm, and the length-to-diameter ratio is 8; the length-to-diameter ratio of the screw in the melting section is 15. The depth gradually decreases from 3mm to 2mm along the screw axis; the groove depth of the screw in the melting section is 2mm, and the aspect ratio is 7. The screw sp...

no. 2 example

[0023] The second embodiment: a high-efficiency plasticizing extruder with a nominal diameter of 45 mm and an aspect ratio of 25. Among them, the barrel in the solid conveying section is a grooved barrel, the aspect ratio is 8, the groove depth is 4mm, the groove width is 8mm, the number of groove heads is 8, and the groove lead is 90mm; the melting section barrel It is a grooved barrel with a length-to-diameter ratio of 12. The groove depth is 4mm and gradually becomes shallower along the screw axis until the end of the melting section disappears. The groove width is 8mm, the number of groove heads is 8, and the groove lead 90mm; the barrel of the rotatable melt conveying section is a smooth barrel with a length-to-diameter ratio of 5. The screw is a reverse compression ratio screw with a lead of 45mm, the number of screw threads is 1, and the normal phase width of the screw edge is 4.5mm; the groove depth of the solid conveying section is 3mm, and the length-to-diameter rati...

no. 3 example

[0025]The third embodiment: a high-efficiency plasticizing extruder with a nominal diameter of 120 mm and an aspect ratio of 35. Among them, the barrel in the solid conveying section is a smooth barrel with an aspect ratio of 12; the barrel in the rotatable melting section is a smooth barrel with an aspect ratio of 14; the barrel in the rotatable melt conveying section is a pin barrel with an aspect ratio of 12. for 9. The screw is an ordinary screw with a lead of 45mm, the number of screw threads is 1, and the normal phase width of the screw edge is 4.5mm; the groove depth of the solid conveying section is 7.5mm, and the length-to-diameter ratio is 12; the groove depth of the melting section gradually changes from 7.5mm to 3.5 mm, the length-to-diameter ratio is 12; the groove depth of the screw in the melting section is 3.5mm, and the length-to-diameter ratio is 9. The screw speed is 60r / min, the driving power is 30kW, the barrel speed of the groove melting section is 12r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com