Tire high-temperature adhesive

A high-temperature adhesive and adhesive technology, applied in the direction of polymer adhesive additives, adhesive types, non-polymer adhesive additives, etc. Unable to meet and other problems, to achieve the effect of improving processing safety, good lateral rigidity, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

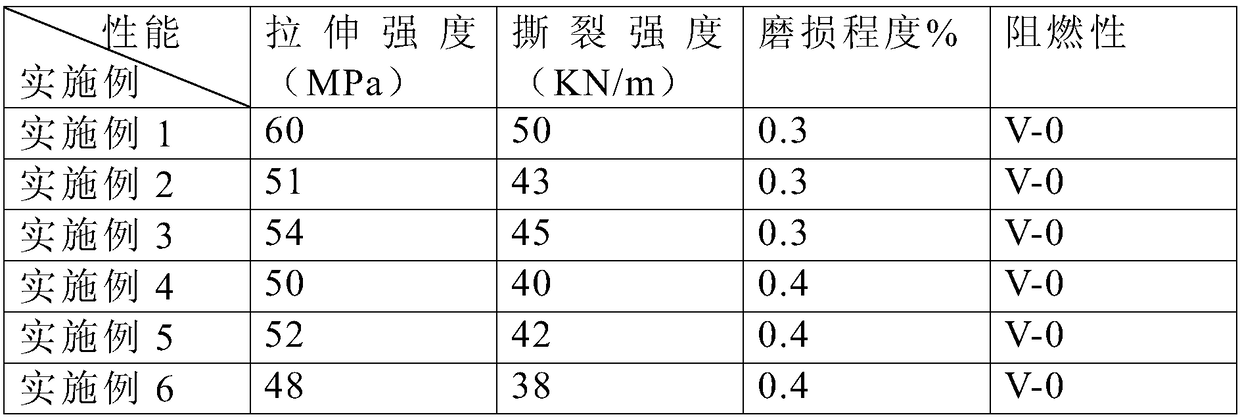

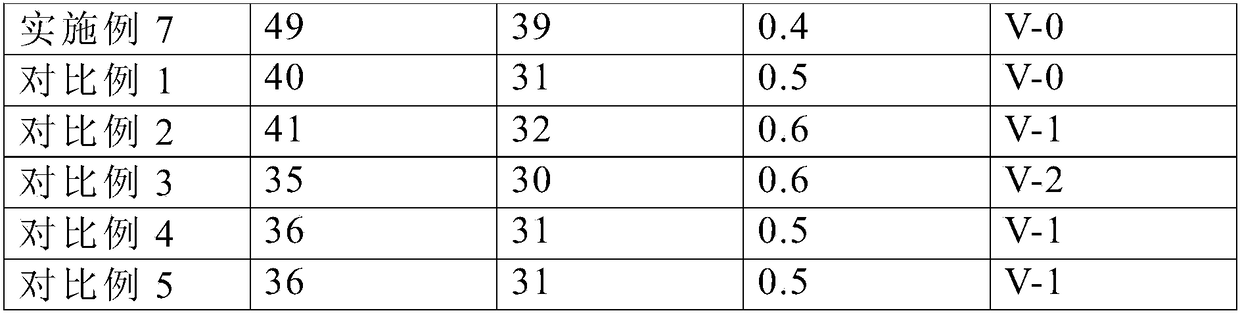

Examples

Embodiment 1

[0032] Ingredients: Weigh the raw materials according to the composition and weight of the adhesive, including 150 parts of xylene, 6 parts of dioctyl ester, 30 parts of neoprene, 20 parts of powdered nitrile, 4 parts of carbon black, and 22 parts of petroleum resin , 6 parts of activator, 8 parts of enhancer, 12 parts of filler, 40 parts of complex, 6 parts of essence, and 5 parts of pigment, wherein, the activator is a mixture of sodium silicate and potassium silicate, and the enhancer is modified palygor Stone powder, the filler is a compound of lignin and kaolinite, and the compound is a compound of photosensitive resin and glass ionomer with a mass ratio of 8:1.

[0033] Filler preparation: Weigh raw materials according to the mass ratio of lignin and kaolinite at 2:1, first put kaolinite in a container, add deionized water and lignin, and continuously add hydrochloric acid to adjust the pH to 6.5 during mechanical stirring. Stir continuously for 1.5 days, then ball mill ...

Embodiment 2

[0038] Ingredients: Weigh raw materials according to the composition and weight of the adhesive, including 140 parts of xylene, 5 parts of dioctyl ester, 25 parts of neoprene, 15 parts of powdered nitrile, 3 parts of carbon black, and 18 parts of petroleum resin , 4 parts of activator, 6 parts of enhancer, 10 parts of filler, 30 parts of complex, 5 parts of essence, 4 parts of pigment, wherein, the activator is a mixture of sodium silicate and calcium silicate, and the enhancer is modified palygor Stone powder, the filler is a compound of lignin and kaolinite, and the compound is a compound of photosensitive resin and glass ionomer with a mass ratio of 7:1.

[0039] Filler preparation: Weigh raw materials according to the mass ratio of lignin and kaolinite at 2:1, first put kaolinite in a container, add deionized water and lignin, and continuously add hydrochloric acid to adjust the pH to 6.5 during mechanical stirring. Stir continuously for 1.5 days, then ball mill the mixtur...

Embodiment 3

[0044] Ingredients: Weigh the raw materials according to the composition and weight of the adhesive, including 160 parts of xylene, 7 parts of dioctyl ester, 35 parts of neoprene, 25 parts of powdered nitrile, 5 parts of carbon black, and 26 parts of petroleum resin , 8 parts of activator, 10 parts of enhancer, 14 parts of filler, 50 parts of complex, 7 parts of essence, and 6 parts of pigment, wherein, the activator is a mixture of calcium silicate and potassium silicate, and the enhancer is modified palygor Stone powder, the filler is a compound of lignin and kaolinite, and the compound is a compound of photosensitive resin and glass ionomer with a mass ratio of 9:1.

[0045]Filler preparation: Weigh raw materials according to the mass ratio of lignin and kaolinite at 2:1, first put kaolinite in a container, add deionized water and lignin, and continuously add hydrochloric acid to adjust the pH to 6.5 during mechanical stirring. Stir continuously for 1.5 days, then ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com