Patents

Literature

272 results about "4-Methyl-1-pentene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

4-Methyl-1-pentene is used as a monomer for olefin polymerisation. The resulting polymer is poly(4-methyl-1-pentene).

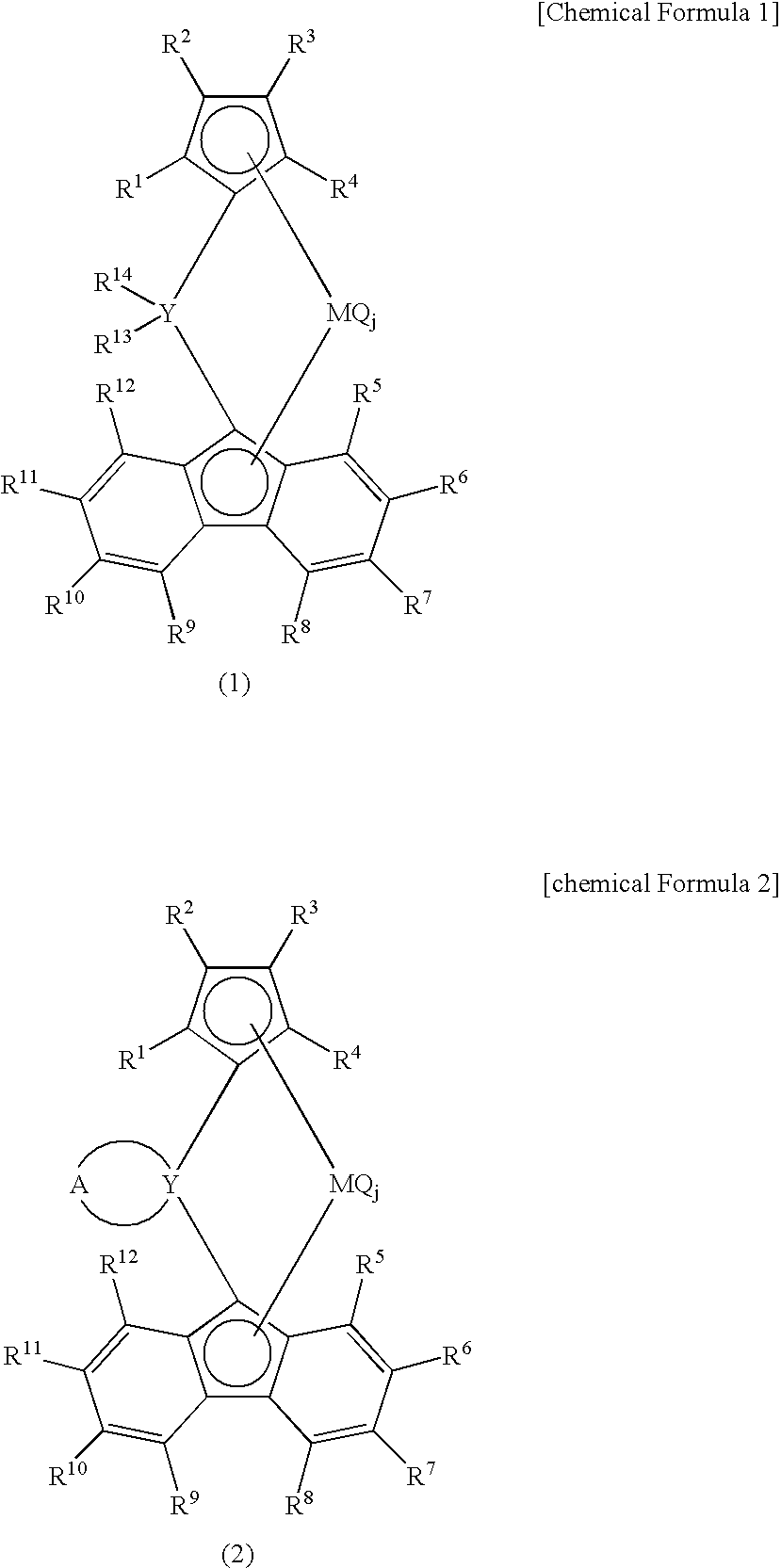

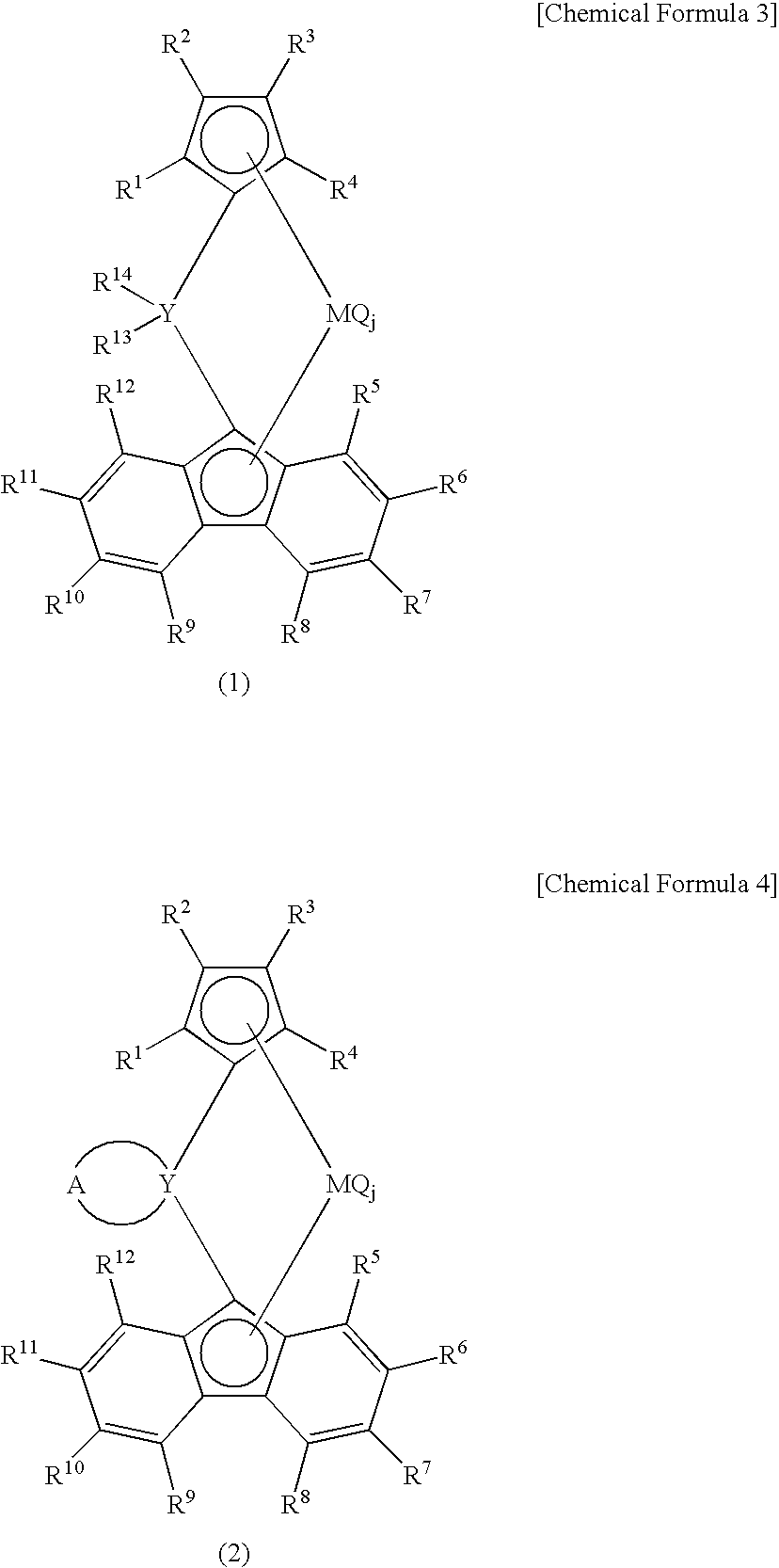

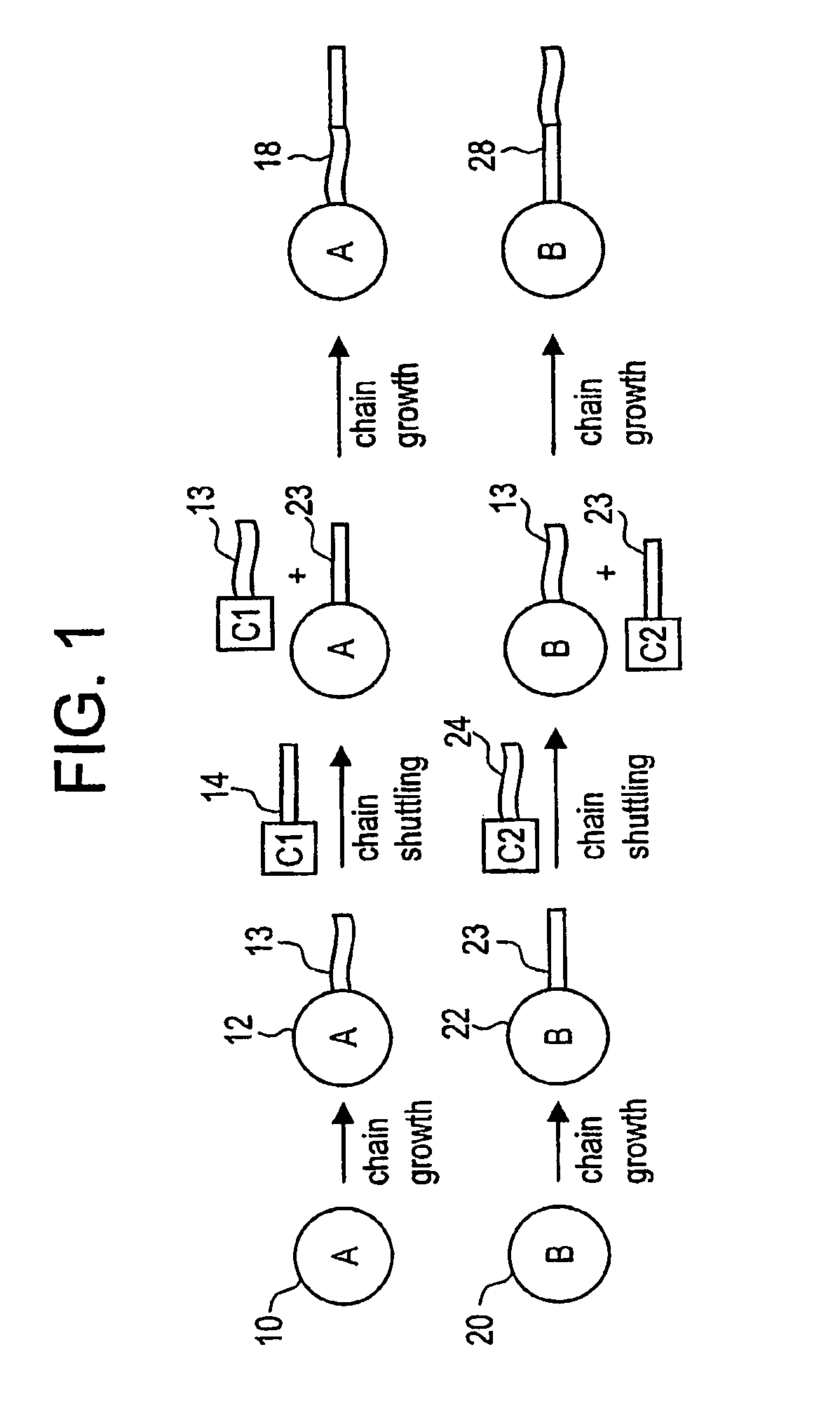

Catalyst Composition Comprising Shuttling Agent for Higher Olefin Multi-Block Copolymer Formation

ActiveUS20080311812A1Improve efficiencyHigh monomer conversion rateWoven fabricsNon-woven fabrics4-Methyl-1-penteneOlefin polymerization

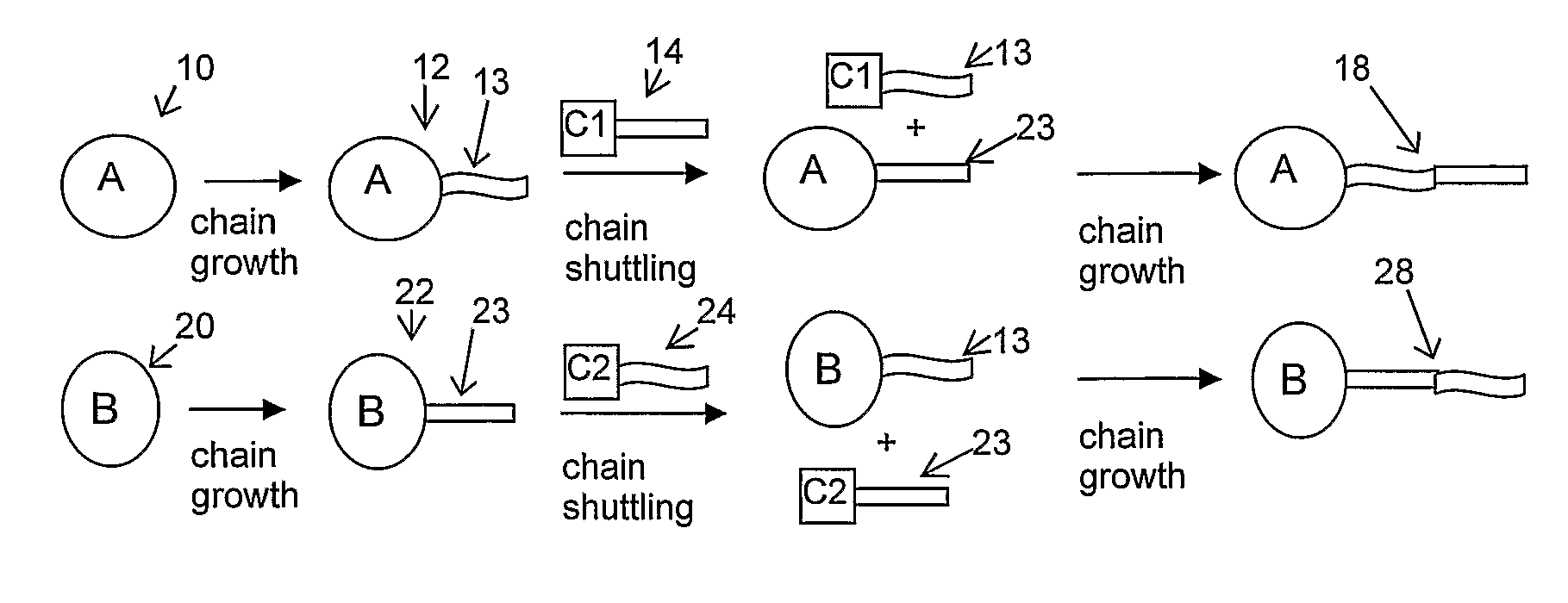

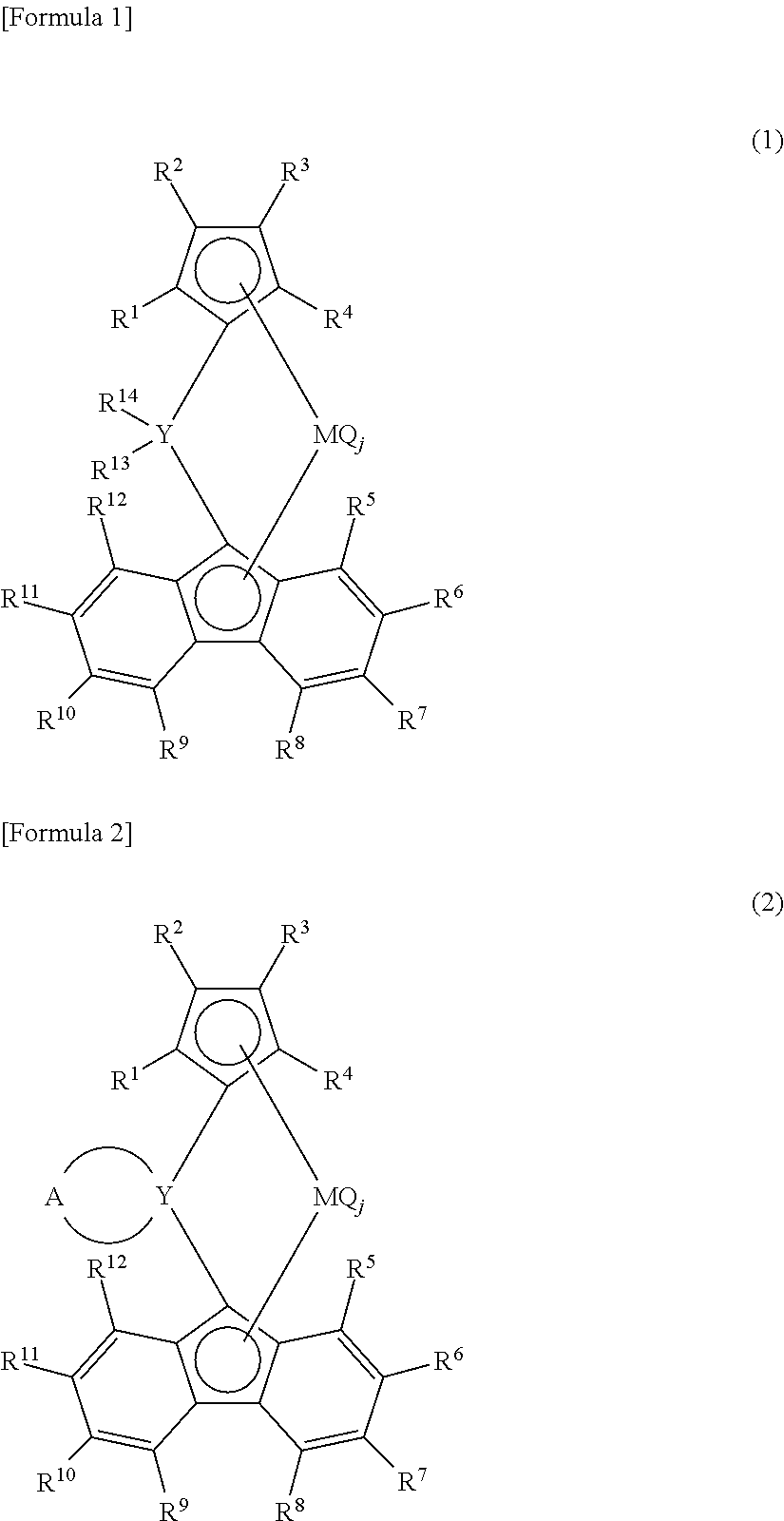

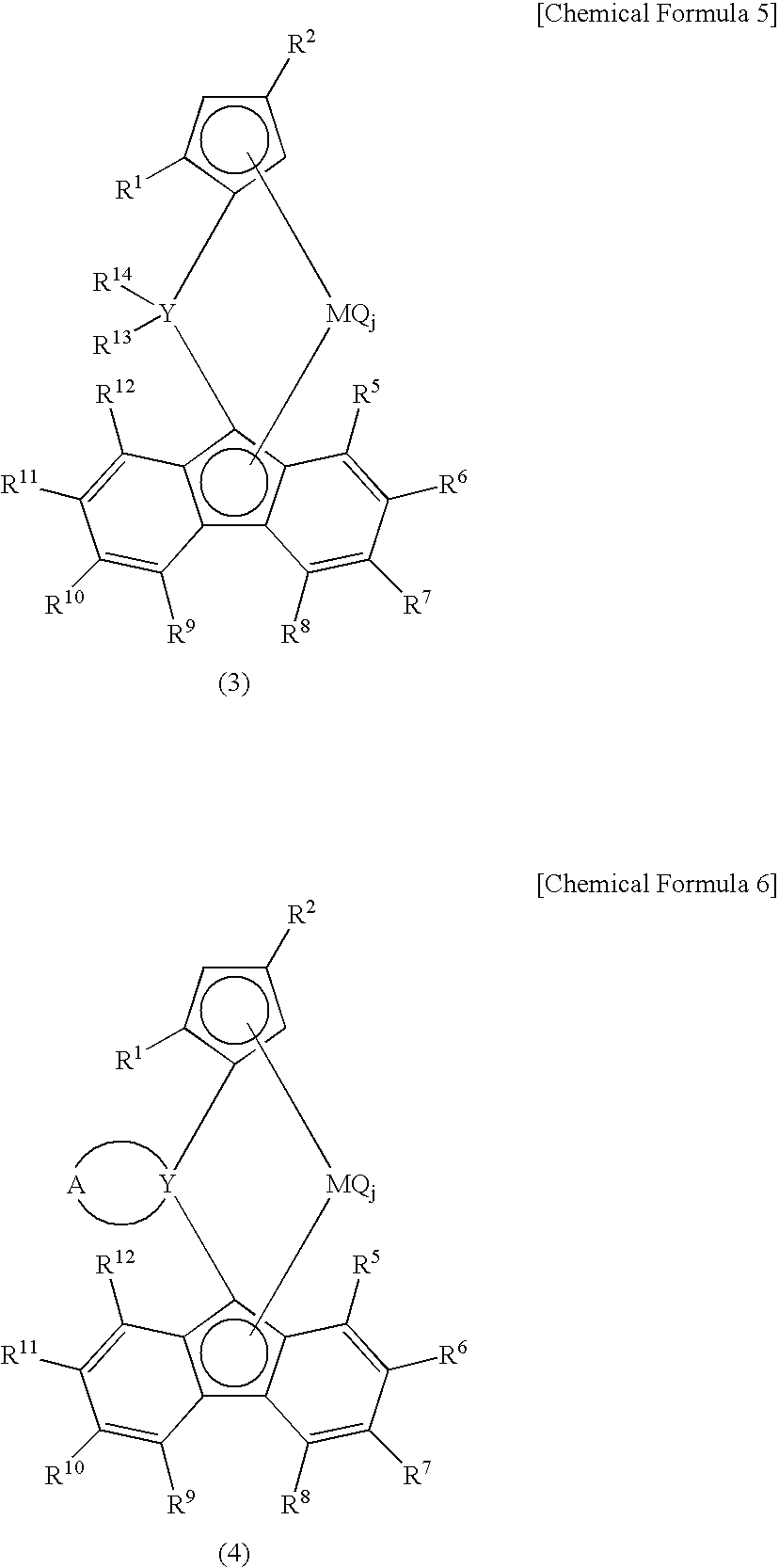

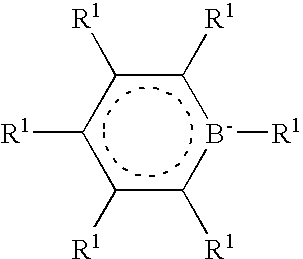

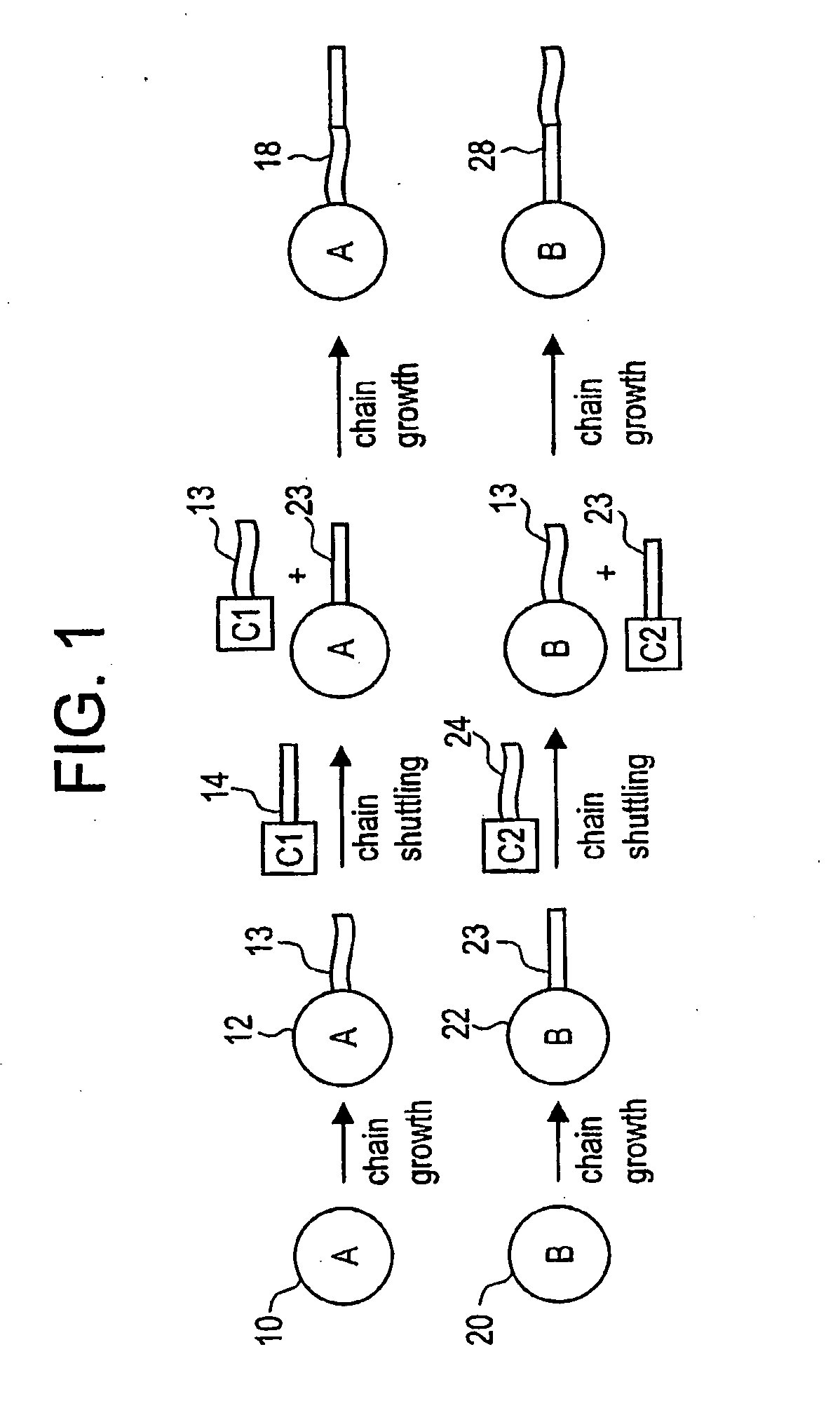

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Catalyst composition comprising shuttling agent for higher olefin multi-block copolymer formation

ActiveUS7951882B2Improve efficiencyWoven fabricsNon-woven fabricsOlefin polymerization4-Methyl-1-pentene

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks differing in chemical or physical properties, are prepared by polymerizing propylene, 4-methyl-1-pentene, or other C4-8α-olefin and one or more copolymerizable comonomers, especially ethylene in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers differing in chemical or physical properties from the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Crosslinkable polyethylene composition

A composition comprising: polyethylene; as a scorch inhibitor, 2,4-diphenyl-4-methyl-1-pentene; as a cure booster, 3,9-divinyl-2,4,8,10-tetra-oxaspiro[5.5]undecane; and an organic peroxide.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

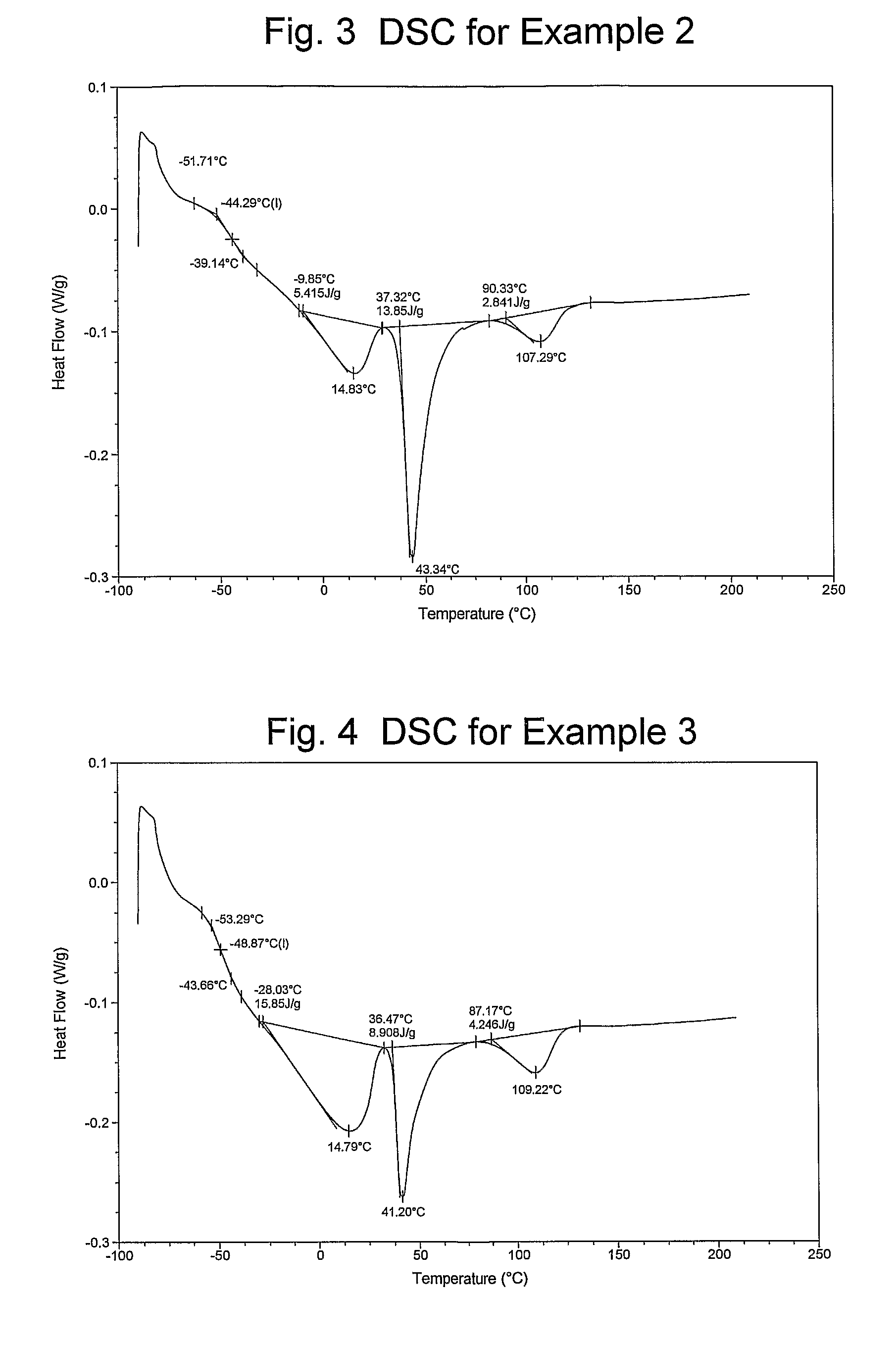

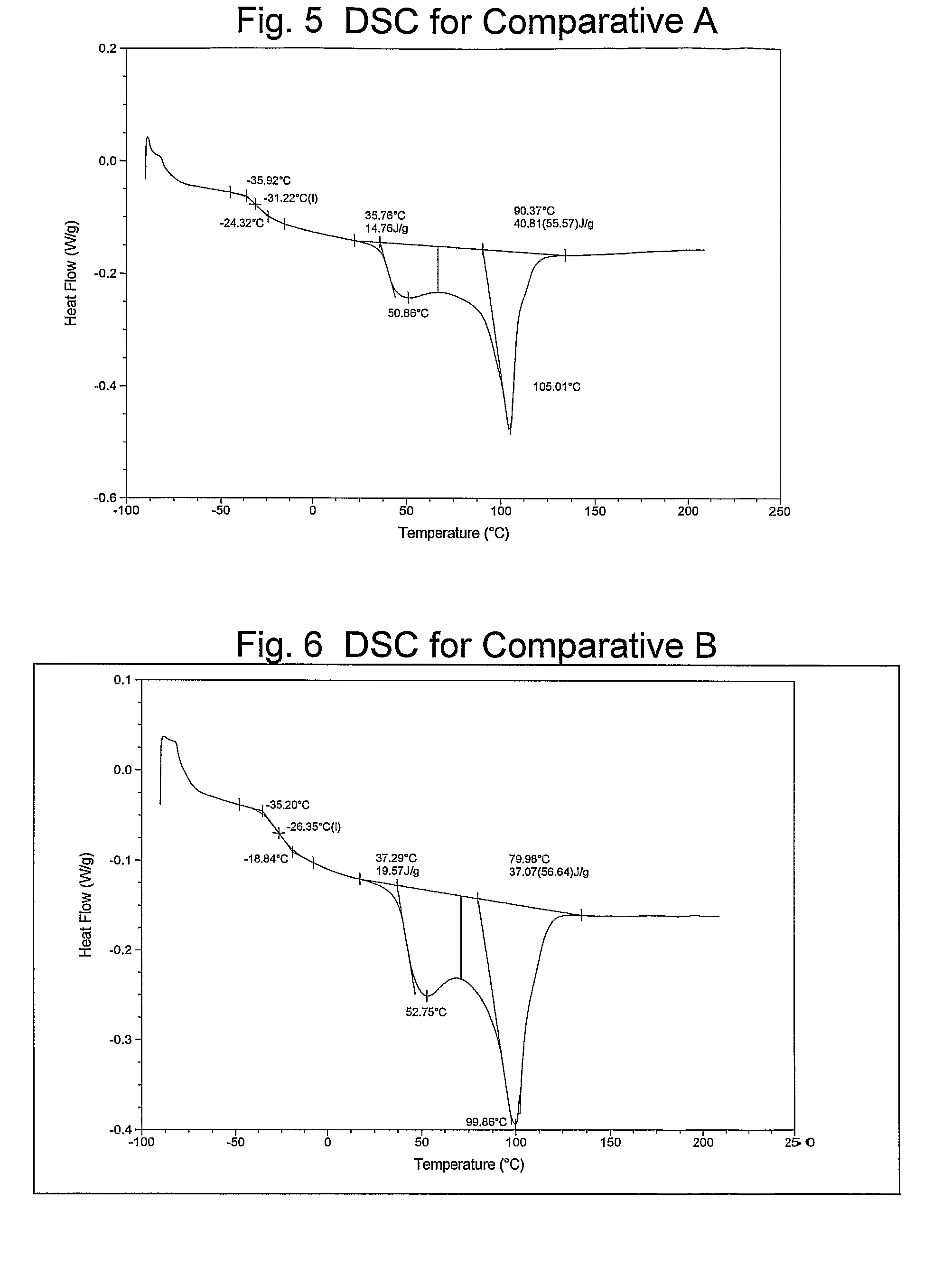

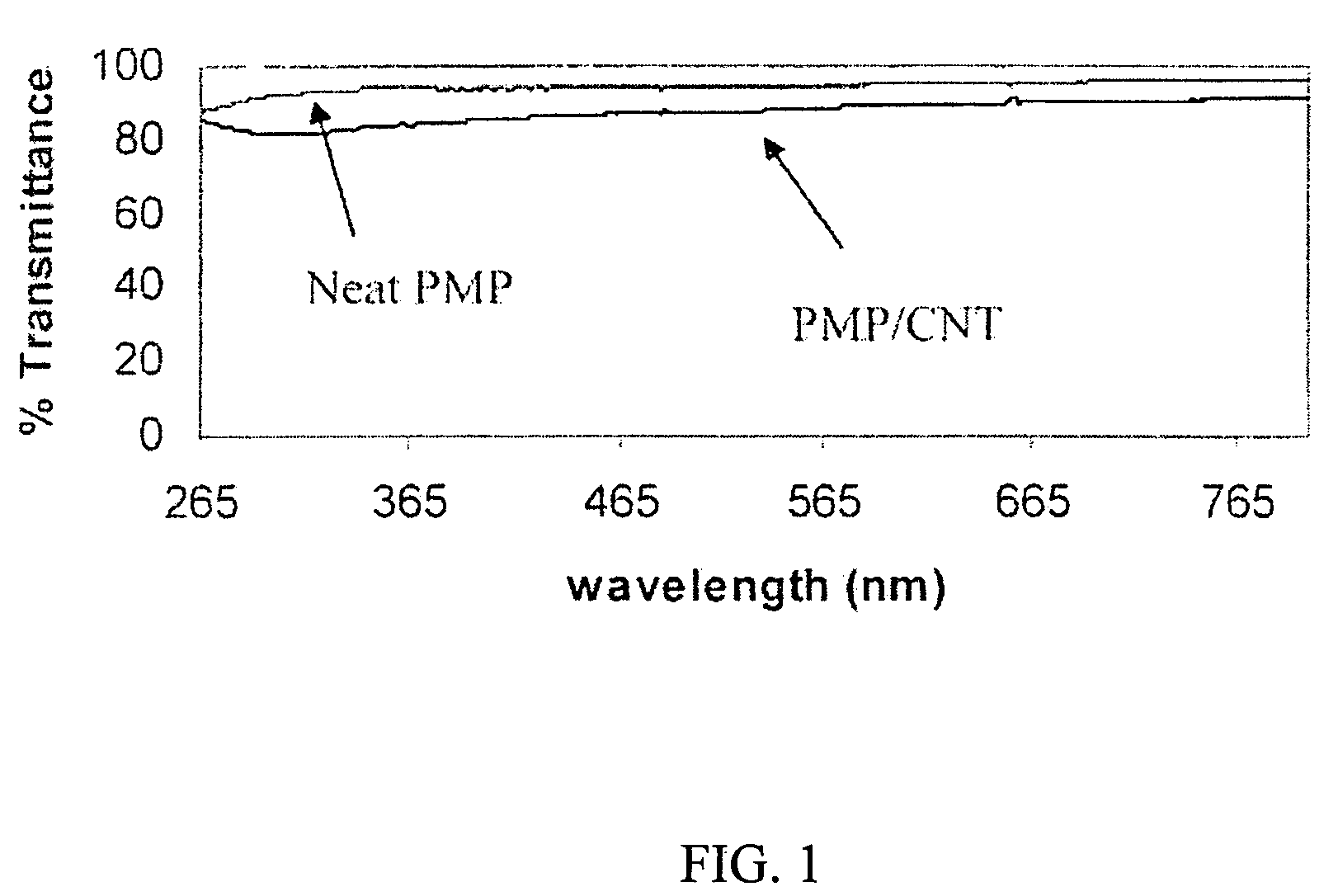

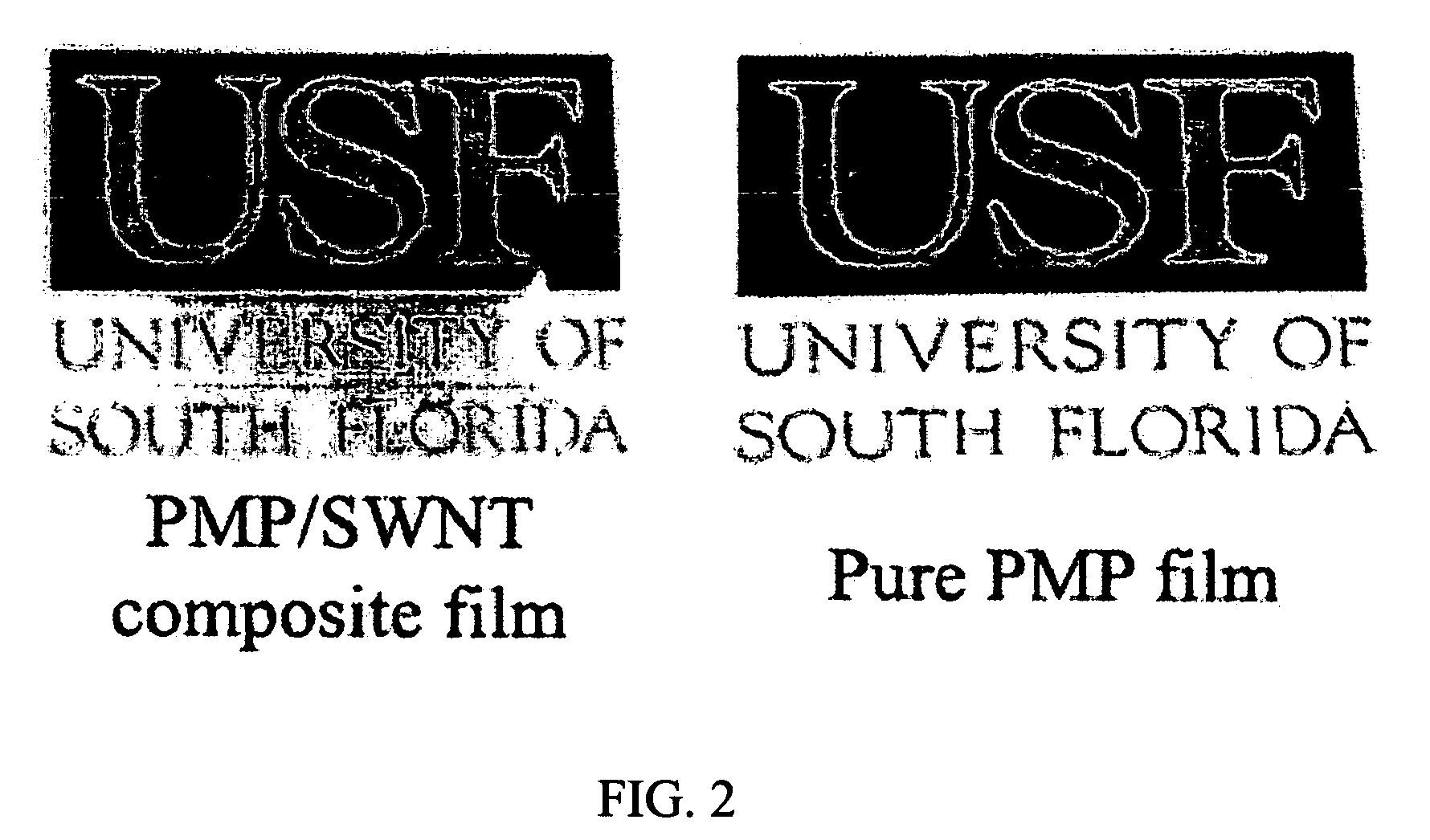

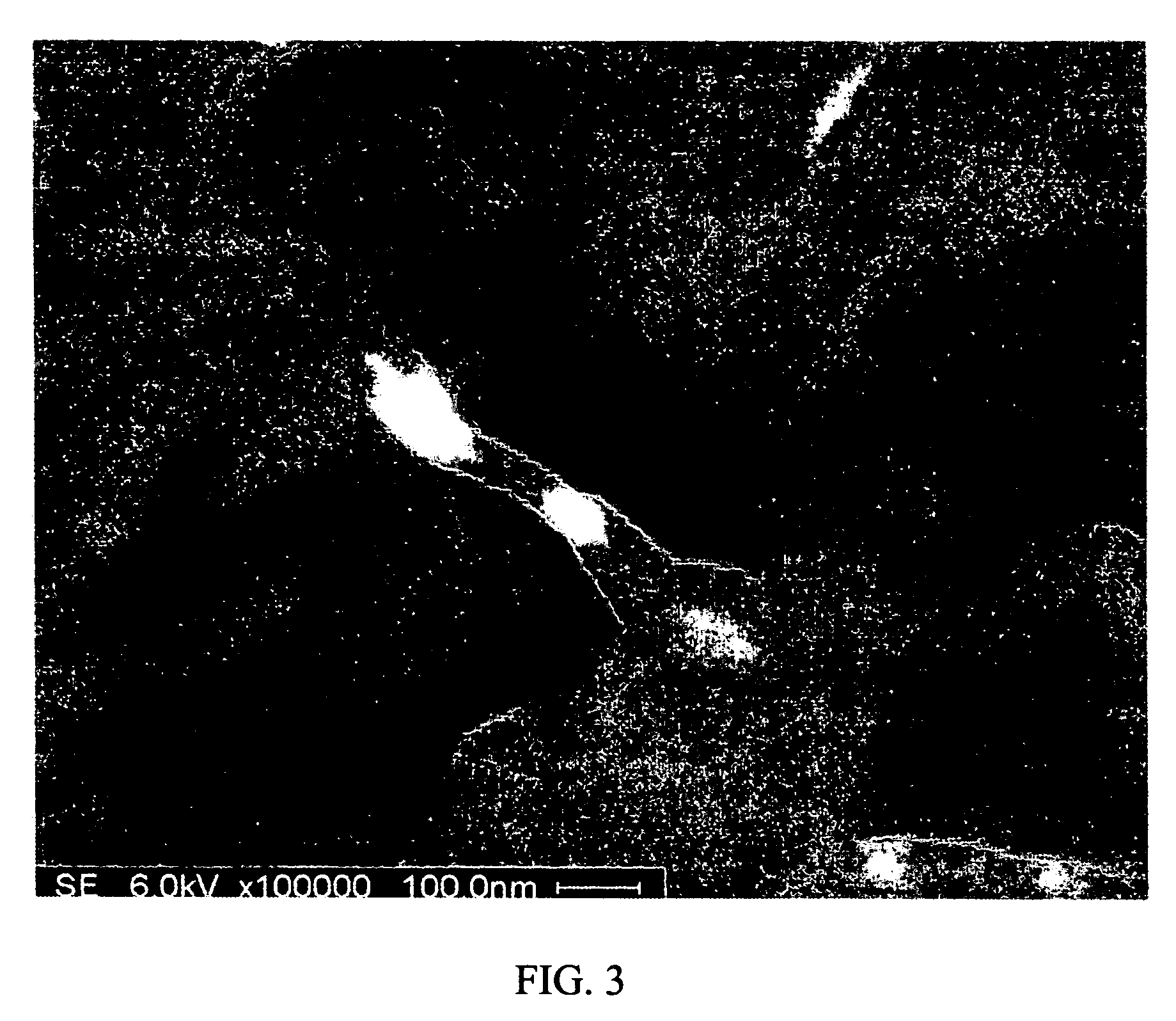

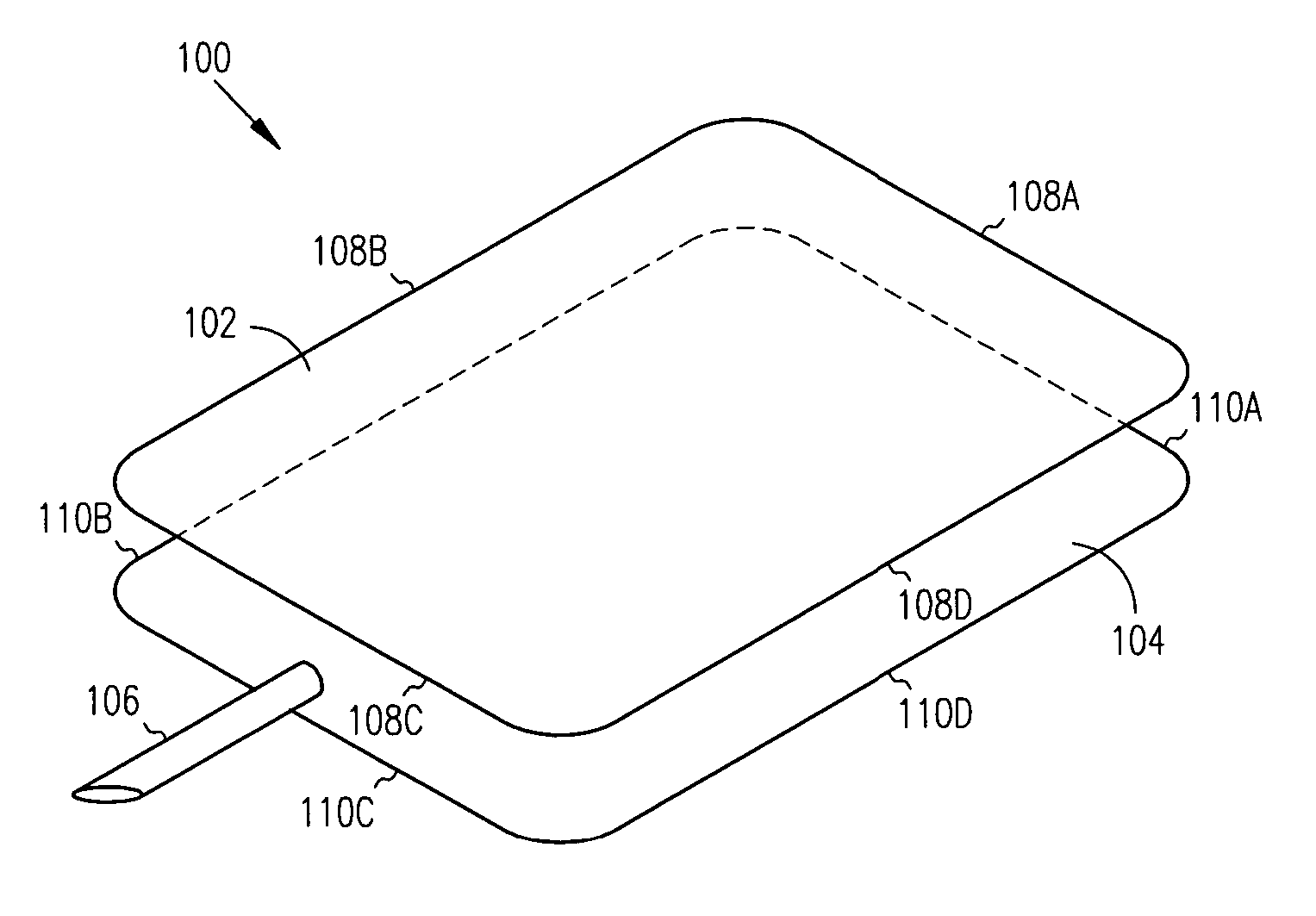

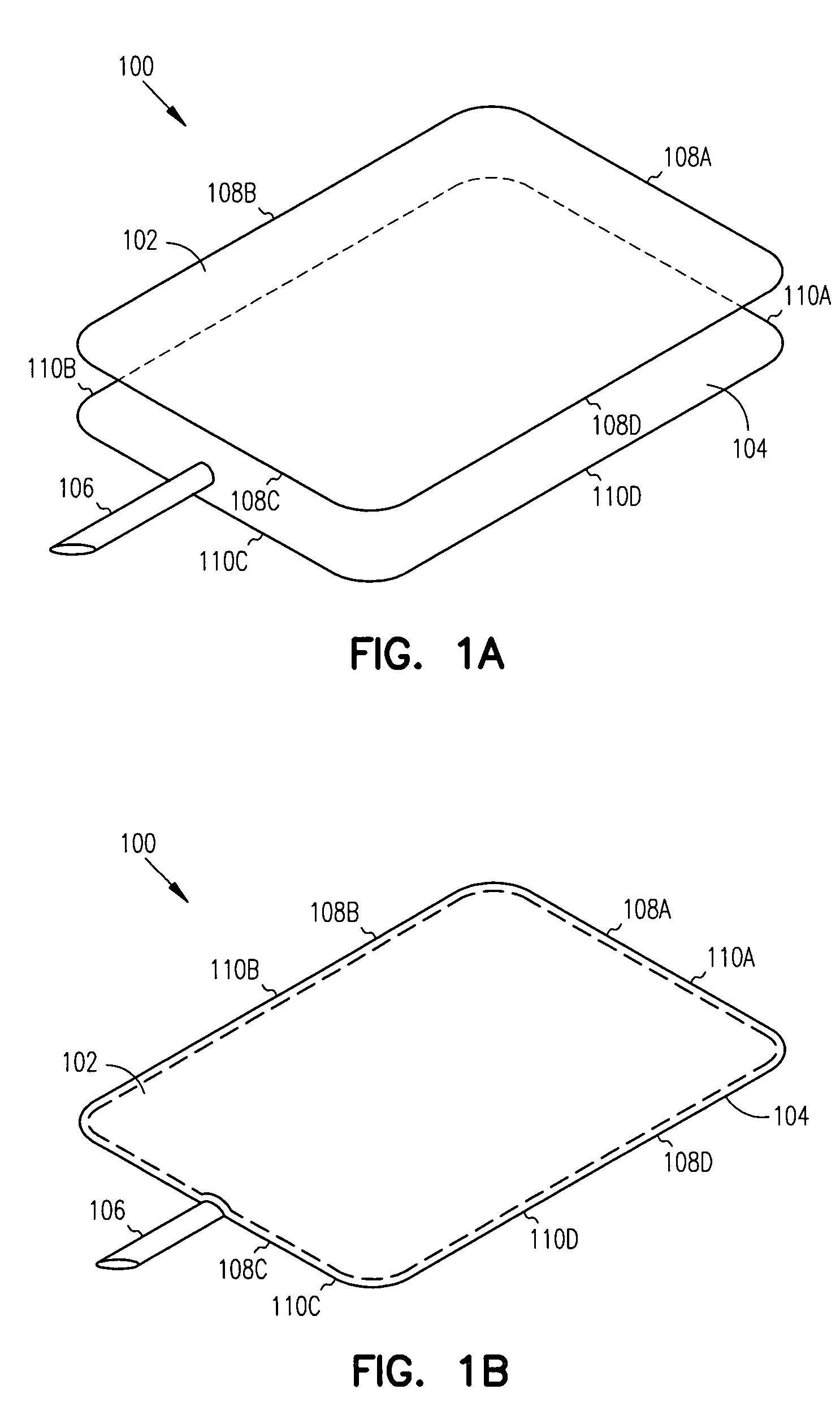

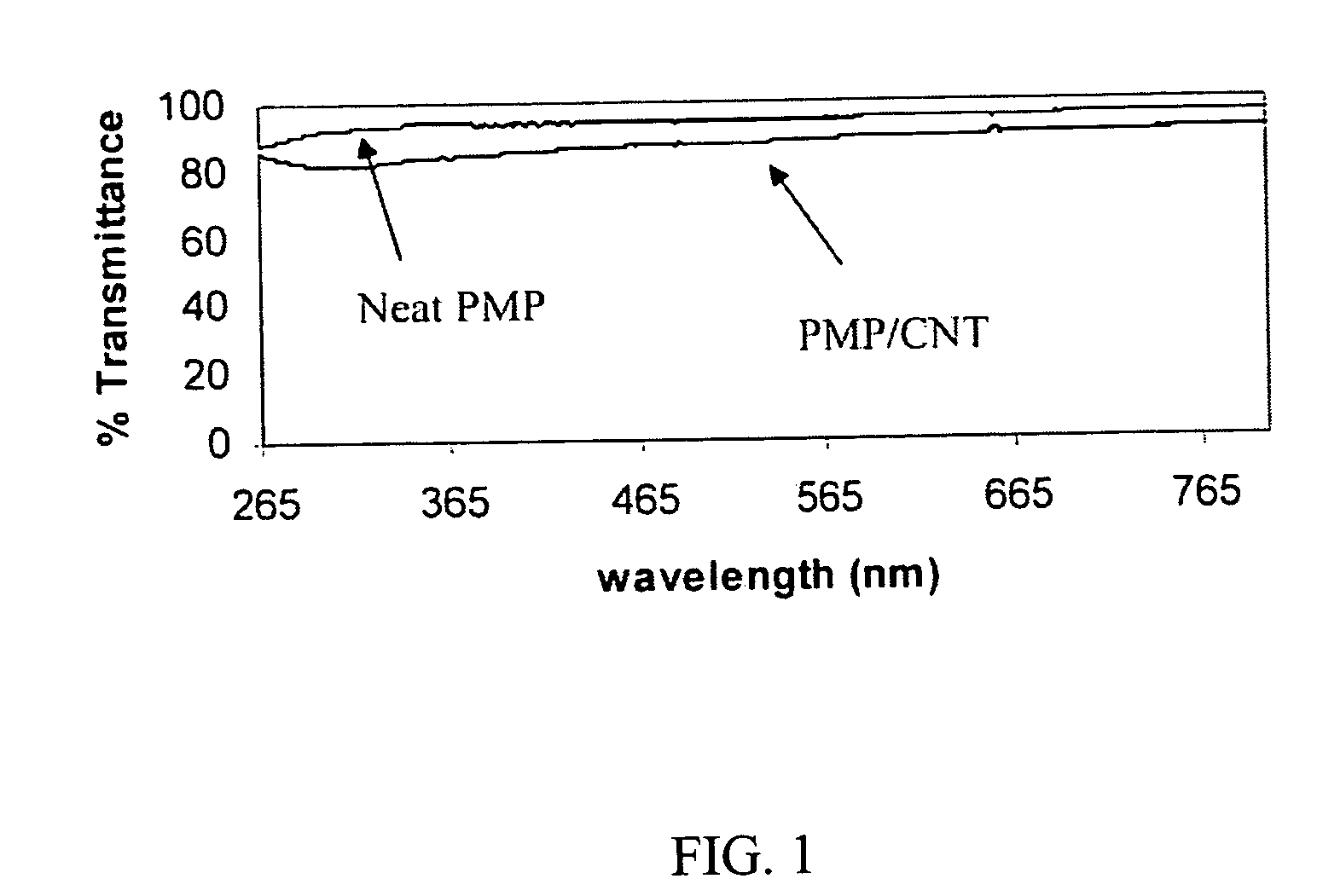

Polymer/carbon nanotube composites, methods of use and methods of synthesis thereof

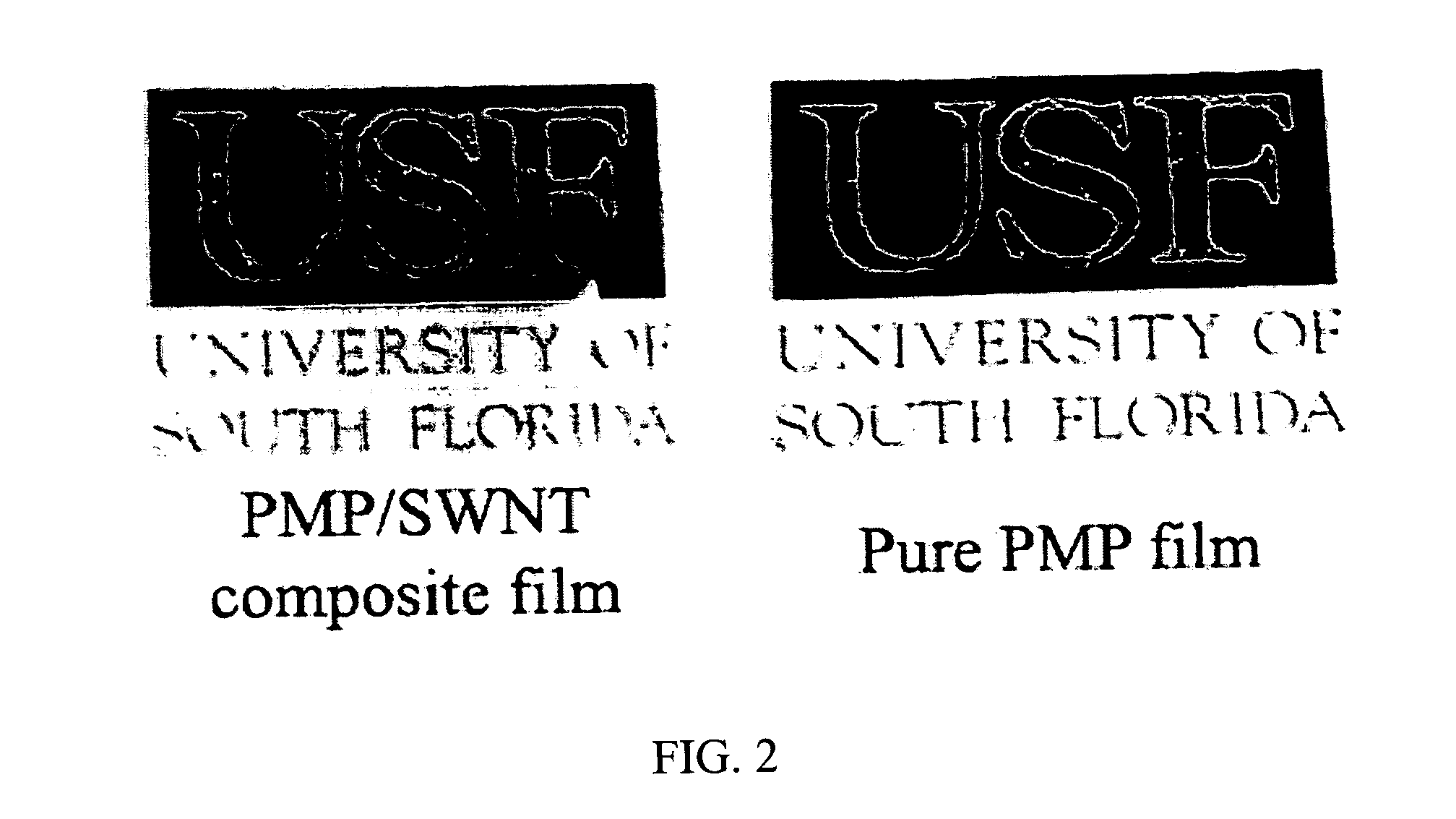

InactiveUS7399794B2Good optical performanceMaintain transparencyMaterial nanotechnologyElectric discharge heatingSynthesis methodsOrganic dye

Novel transparent composites composed of single wall carbon nanotubes incorporated into the matrix of a polymer are utilized in services wherein the composites are exposed to ionizing radiation, including galactic cosmic radiation. Accordingly, the composites are useful in deep space applications like space vehicles, space stations, personal equipment as well as applications in the biomedical arts and atom splitting research. The composites can be modified with organic dyes containing at least one phenyl ring and the resulting doped composite is useful as a radiation detector. The preferred polymer is poly(4-methyl-1-pentene).

Owner:UNIV OF SOUTH FLORIDA

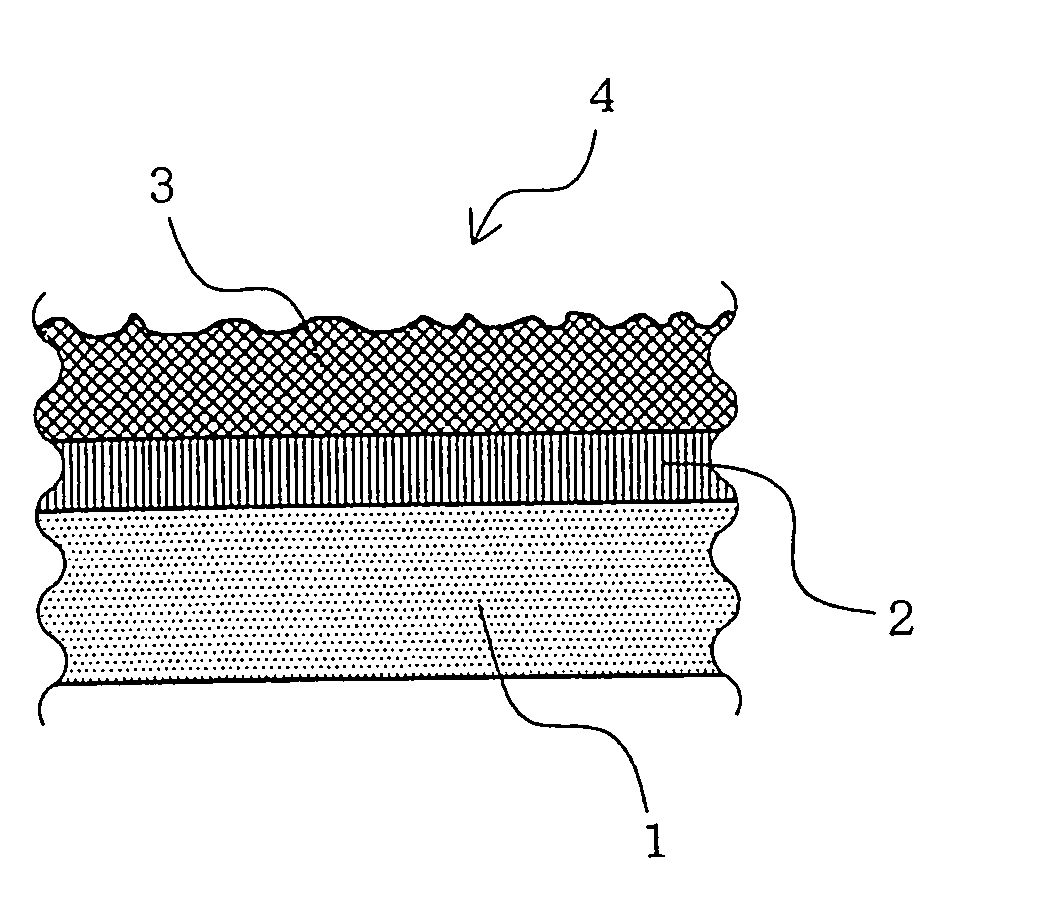

Release liner and pressure-sensitive adhesive tape or sheet employing the same

ActiveUS20050266195A1Stable separationReduce the voltage levelFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

The release liner includes a release layer constituted of at least one polyolefin resin, wherein the release layer has surface irregularities. The surface irregularities of the release layer may be constituted of recesses and protrusions which are irregularly different in shape and have been disposed in irregular arrangement. The release layer preferably has a surface roughness Ra of 1-3 μm. As the polyolefin resin constituting the release layer can be used at least one polyolefin resin selected from the group consisting of polyethylenes, polypropylene, polybutenes, poly(4-methyl-1-pentene), and copolymers of ethylene with one or more α-olefins having 3-10 carbon atoms.

Owner:NITTO DENKO CORP

4-METHYL-1-PENTENE/a-OLEFIN COPOLYMER, COMPOSITION COMPRISING THE COPOLYMER AND 4-METHYL-1-PENTENE COPOLYMER COMPOSITION

ActiveUS20120220728A1Preferable in of flexibilityPreferable in of mechanical propertyPolymer scienceStress relaxation

The present invention provides a 4-methyl-1-pentene / α-olefin copolymer being excellent in lightness, stress absorption, stress relaxation, vibration damping properties, scratch resistance, abrasion resistance, toughness, mechanical properties and flexibility, having no stickiness during molding operation and being excellent in the balance among these properties; a composition comprising the polymer; and uses thereof. The 4-methyl-1-pentene / α-olefin copolymer (A) of the present invention satisfies specific requirements, and comprises 5 to 95 mol % of a structural unit (i) derived from 4-methyl-1-pentene, 5 to 95 mol % of a structural unit (ii) derived from at least one kind of α-olefin selected from α-olefins having 2 to 20 carbon atoms excluding 4-methyl-1-pentene and 0 to 10 mol % of a structural unit (iii) derived from a non-conjugated polyene, provided that the total of the structural units (i), (ii), and (iii) is 100 mol %.

Owner:MITSUI CHEM INC

Capacitor film with low density polyethylene as substrate and preparation method thereof

ActiveCN102964658AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricEpoxyPolyvinyl alcohol

The invention discloses a capacitor film with low density polyethylene as substrate and a preparation method thereof. The capacitor film comprises the following raw materials by weight: 50-55 parts of LDPE (low density polyethylene), 20-25 parts of LLDPE (linear low density polyethylene), 10-15 parts of homo-polymer, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.8-1.2 parts of poly-4-methyl-1-pentene, 5-10 parts of calcium carbonate, 2-4 parts of hydrotalcite, 1.3-1.8 parts of zinc dialkyl dithiophosphate, 0.4-0.6 part of phthalic acid ester, 0.4-0.7 part of smoke sheet rubber, 1-3 parts of zinc stearate and 0.9-1.3 parts of modified wood ash. The invention mainly adopts low density polyethylene assisted with linear low density polyethylene; and various accessories and additives are subjected to mixing and extrusion, blown film sizing and cutting to prepare the capacitor film. The preparation method is simple; and diatomite, hydrotalcite and modified wood ash are added into the raw materials at the same time to enhance barrier property and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength, and good heat sealing performance.

Owner:安徽芯智达电子科技有限公司

Capacitor film containing modified attapulgite and preparation method thereof

ActiveCN102964664AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethylenePolyvinyl alcohol

The invention discloses a capacitor film containing modified attapulgite and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 30-40 parts of homogeneous ethylene / alpha olefin copolymer, 25-30 parts of metallocene linear low-density polyethylene resin, 13-18 parts of LDPE low-density polyethylene, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 1.2-1.5 parts of poly-4-methyl-1-pentene, 7-9 parts of modified attapulgite, 0.8-1.2 parts of an antioxidant DLTP, 0.6-0.8 part of tributyl citrate, 1.4-1.8 parts of dioctyl maleate, 4-6 parts of calcium stearate, 1.4-1.8 parts of vinyl tri (beta-methoxy ethyoxyl) silane and 0.8-1.2 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:ANHUI YIDA ELECTRONICS

Capacitor thin film with homo-polypropylene as substrate and preparation method thereof

InactiveCN103102587AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor thin film with homo-polypropylene as a substrate and a preparation method of the capacitor thin film. The composition raw materials of the thin film in parts by weight are as follows: 20-30 parts of LDPE (Low Density Polyethylene), 30-40 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of dicyclopentadienyl iron, 0.9-1.1 parts of poly-4-methyl-1-pentene, 0.5-0.7 part of permanent white, 9-11 parts of nano-clay, 2.0-2.5 parts of catechol, 1.2-1.6 parts of di(ethylene glycol) benzoate, 1.3-1.8 parts of dibutyl phthalate, 4-6 parts of calcium stearate, 1.5-2.0 parts of vinyl triethoxy silane, and 2.5-3.0 parts of modified tree ash. The thin film provided by the invention is manufactured by taking the homo-polypropylene as a main raw material and the low density polyethylene as an auxiliary raw material, and enabling a plurality of auxiliary additives and the homo-polypropylene as well as the low density polyethylene to be subjected to mixed extrusion, film blowing sizing, and cutting; the preparation method is simple; simultaneously, the diatomite, the nano-clay and the modified tree ash are added into the raw materials to enhance barrier property and air tightness of the thin film; and the thin film has the characteristics of good pressure resistance, good impact resistance, heat seal strength, and good heat seal performance.

Owner:TONGLING YIHENGDA ELECTRONICS

Environmentally-friendly cable filling material and preparation method thereof

ActiveCN103351548AHigh volume resistivityHigh temperature resistantPlastic/resin/waxes insulatorsLow-density polyethyleneWear resistant

The invention provides an environmentally-friendly cable filling material and a preparation method thereof. The material is characterized by comprising the following raw materials by weight parts: 55-59 parts of SG-4PVC resin, 21-24 parts of metallocene linear low-density polyethylene, 3-4 parts of Mo2B5, 4-5 parts of hafnium diboride, 12-14 parts of polyphenylene thioether, 4-6 parts of poly-4-methyl-1-pentene, 32-36 parts of bentonite, 12-14 parts of alumina, 21-24 parts of barium sulfate, 2-3 parts of zinc oxide, 1-2 parts of an accelerator TMTM, 2-3 parts of bis-tetradecene alcohol ester, 2-3 parts of a silane coupling agent KH 550, 1-2 parts of a cross-linking agent TAC, 4-6 parts of epoxy tetrahydro dicapryl phthalate, 1-2 parts of tributyl tin chloride, 10-12 parts of carbon black N 660, 14-17 parts of precipitated silica, and 6-8 parts of modified diatomite. The cable filling material provided by the invention is high in volume resistivity, high temperature resistant, good in insulating property, relatively good in electrical property and good in wear-resistant property.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

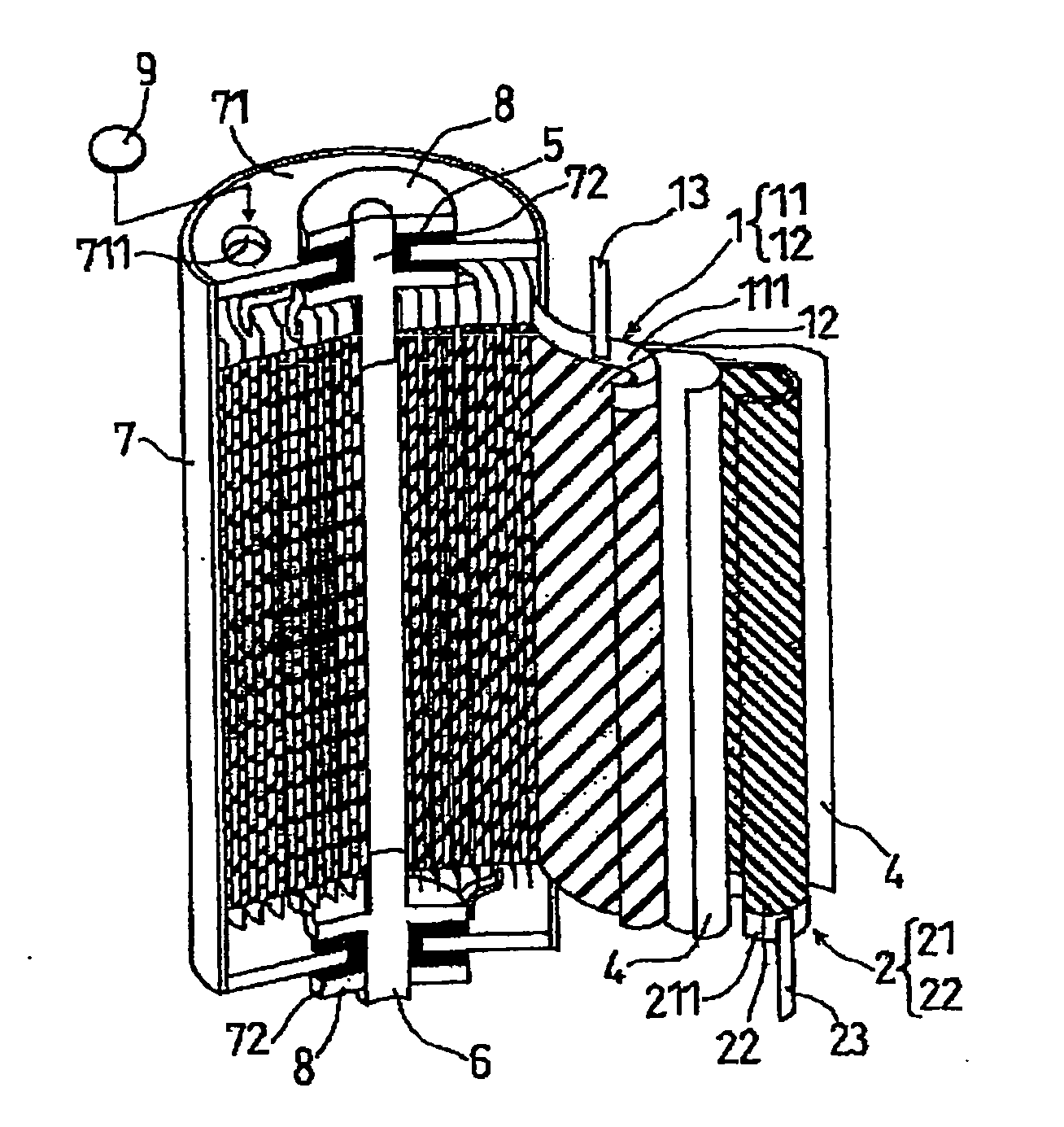

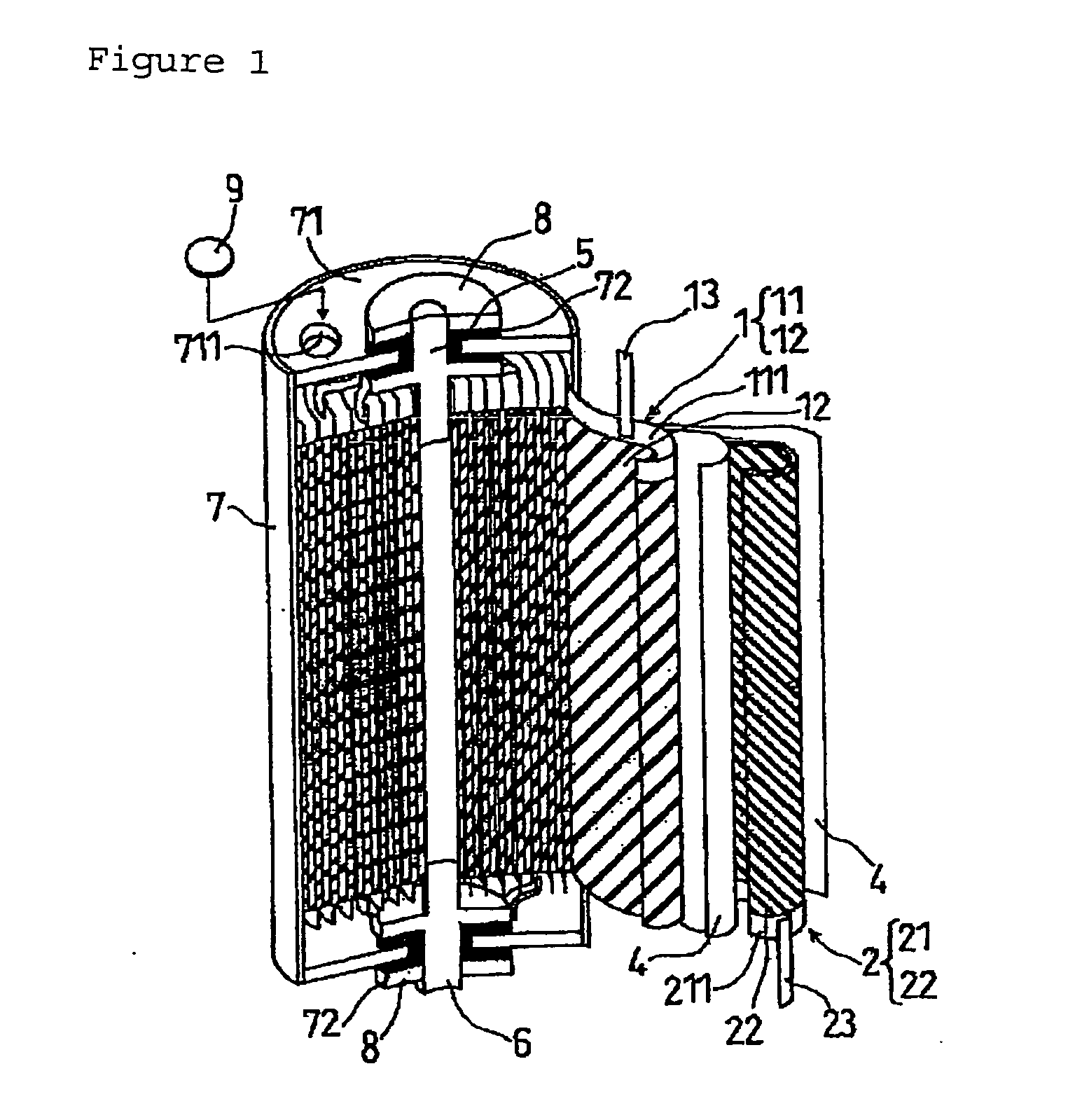

Separator for battery and lithium ion battery using the same

ActiveUS20060073389A1High strengthImprove heat resistanceSecondary cellsCell component detailsPorosityEngineering

A battery separator of the invention is obtained by press forming a meltblown nonwoven fabric comprising 4-methyl-1-pentene polymer or a 4-methyl-1-pentene / α-olefin copolymer, the battery separator having an average fiber diameter of 0.8 to 5 μm, a basis weight of 9 to 30 g / m2, a porosity of 30 to 60%, and a load at 5% elongation in the MD direction (longitudinal direction) of not less than 1.2 (kg / 5 cm width). A lithium ion secondary battery of the invention includes the battery separator.

Owner:MITSUI CHEM INC +1

Capacitor film containing modified talc and preparation method thereof

The invention discloses a capacitor film containing modified talc and a preparation method thereof. The capacitor film comprises the following raw materials, by weight: 57-63 parts of metallocene polypropylene resin, 35-45 parts of bisphenol A polycarbonate, 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyvinyl alcohol, 1-2 parts of aluminum hydroxide, 1-2 parts of polyisobutylene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 1.0-1.5 parts of poly-4-methyl-1-pentene, 5-7 parts of vermiculite, 3-5 parts of modified talcum powder, 0.7-1.3 parts of an antioxidant 1010, 0.7-0.9 part of propylene glycol adipate polyester, 0.3-0.5 part of di(2-ethylhexyl)-4,5-epoxy tetrahydrophthalate, 3-5 parts of calcium stearate and 2.2-2.6 parts of modified wood ash. The preparation method provided by the invention is simple; addition of diatomite, modified attapulgite and modified wood ash enhances resistance and air tightness of the film; besides, the capacitor film has characteristics of good pressure resistance, impact resistance, high heat sealing strength and good heat sealing performance.

Owner:BENGBU LIQUN ELECTRONICS

High-performance reflective film and its preparation method

ActiveCN103552329AImprove stiffnessImprove flex resistanceMirrorsDiffusing elementsPolyethylene glycolUltraviolet

A high-performance reflective film comprises a reflective core layer which is composed of polyethylene glycol terephthalate, titanium dioxide particles, polyethylene glycol, poly4-methyl-1-pentene and a benzotriazole ultraviolet absorbent. The reflective film also comprises a diffusion layer which covers the upper surface of the reflective core layer. The diffusion layer is composed of polymethyl methacrylate, MBS resin, polymethyl methacrylate particles, a benzotriazole ultraviolet absorbent and an antistatic agent. The reflective film also comprises an anti-bonding layer which covers the lower surface of the reflective core layer and is composed of polyethylene glycol terephthalate, silicon dioxide particles and an antistatic agent. A preparation method of the reflective film comprises the following steps: A, a diffusion master batch is prepared; B, a reflective master batch is prepared; C, an anti-bonding master batch is prepared; and D, after coextru-lamination, longitudinal stretching is firstly conducted, and transverse stretching is then carried out. A diffusion layer is arranged on one side of the reflective core layer. The diffusion layer has photodiffusion performance, antistatic performance and a function of increasing stiffness and flex-resistance of the reflective film.

Owner:NINGBO DXC NEW MATERIAL TECH

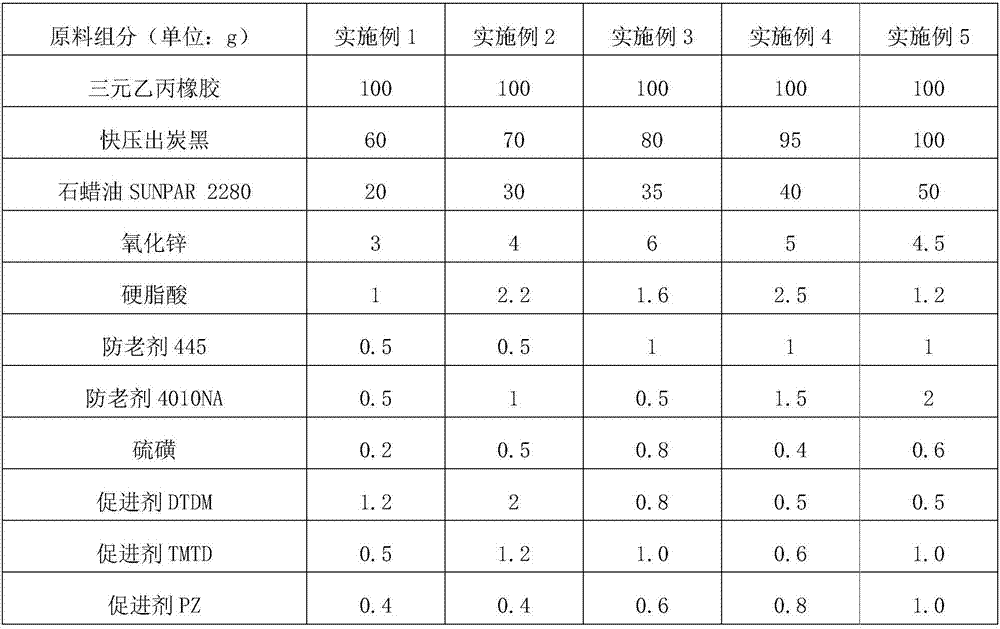

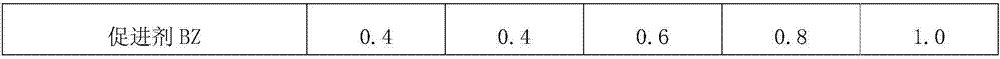

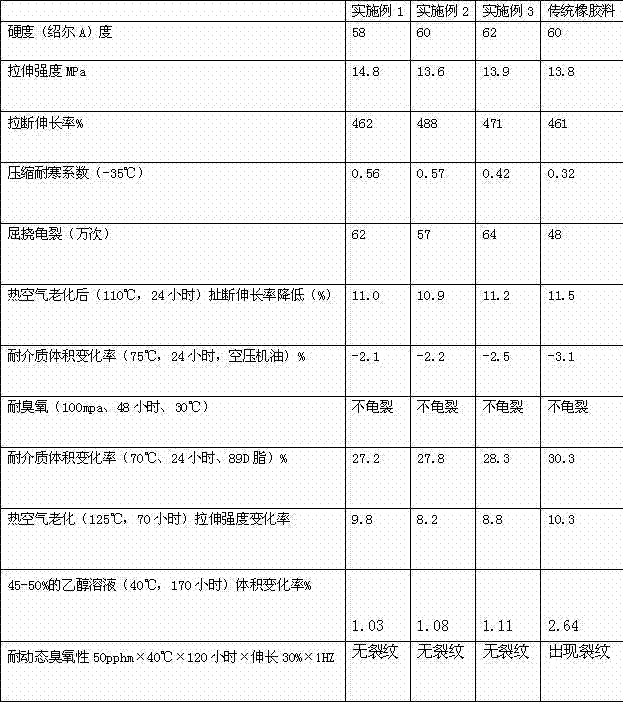

Heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, preparation method, application and application product thereof

ActiveCN107189236AImprove heat aging resistanceGood physical and mechanical propertiesVulcanizationPolymer science

The invention discloses a heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, a preparation method, application and an application product thereof. The composition is prepared from 100 parts of EPDM rubber, 50 to 130 parts of carbon black, 10 to 60 parts of paroline, 2 to 8 parts of zinc oxide, 0.5 to 3 parts of stearic acid, 1 to 6 parts of an anti-aging agent, 0.2 to 1 part of sulfur and 1 to 6 parts of an accelerator. Compared with a sulfur vulcanized EPDM rubber composition prepared in the prior art, the composition has the advantages that heat aging resistance and low compression set are remarkably increased, and the composition is applied to rubber products having the requirements on heat aging resistance and low pressure change, and is particularly applied to an outer adhesive layer of a rubber hose which adopts a poly-4-methyl-1-pentene (TPX) coating and vulcanizing technology; meanwhile, the preparation method of the composition is simple, the vulcanization temperature is lower, and the purpose of saving energy is achieved.

Owner:NANJING ORIENTLEADER TECH CO LTD

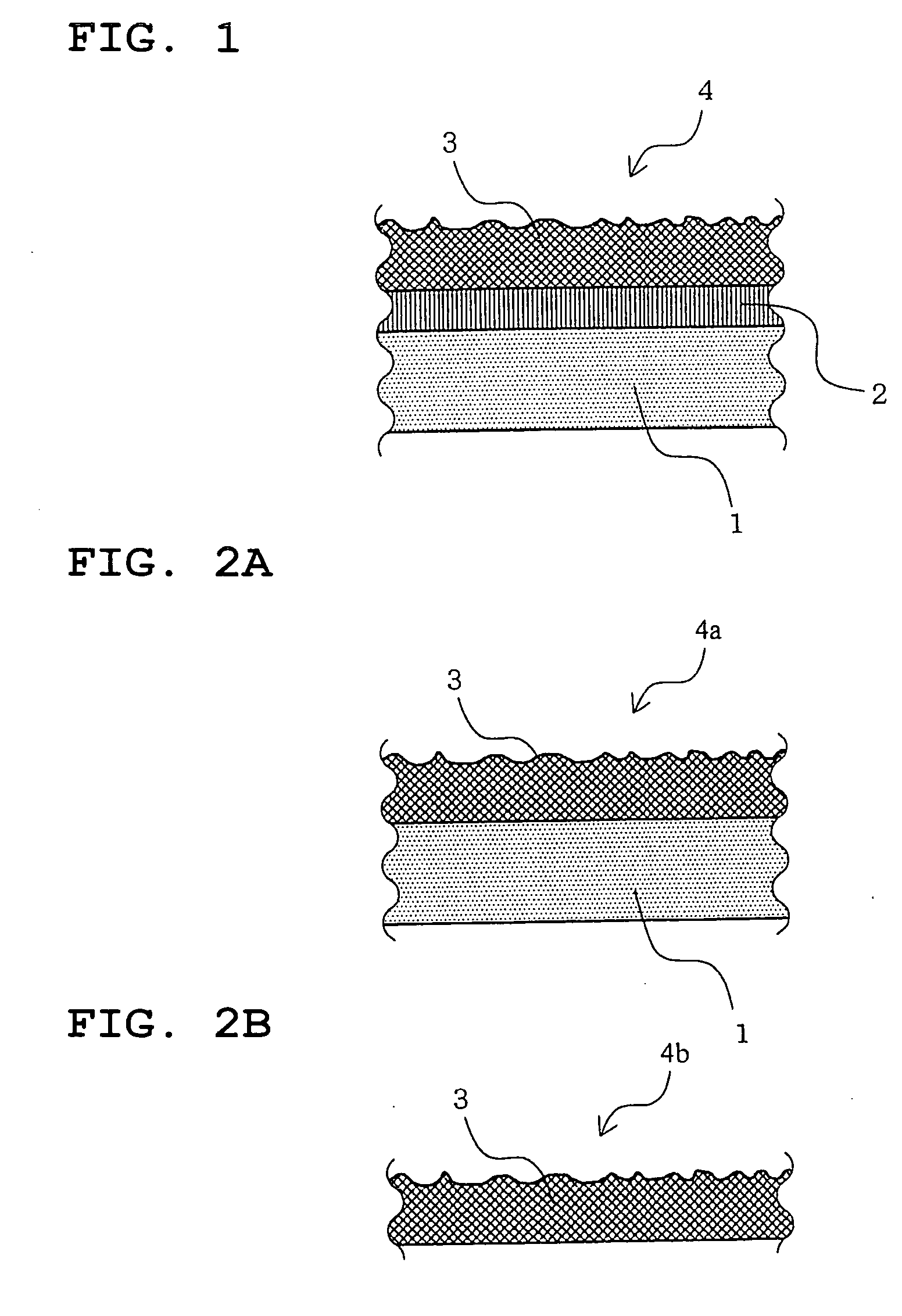

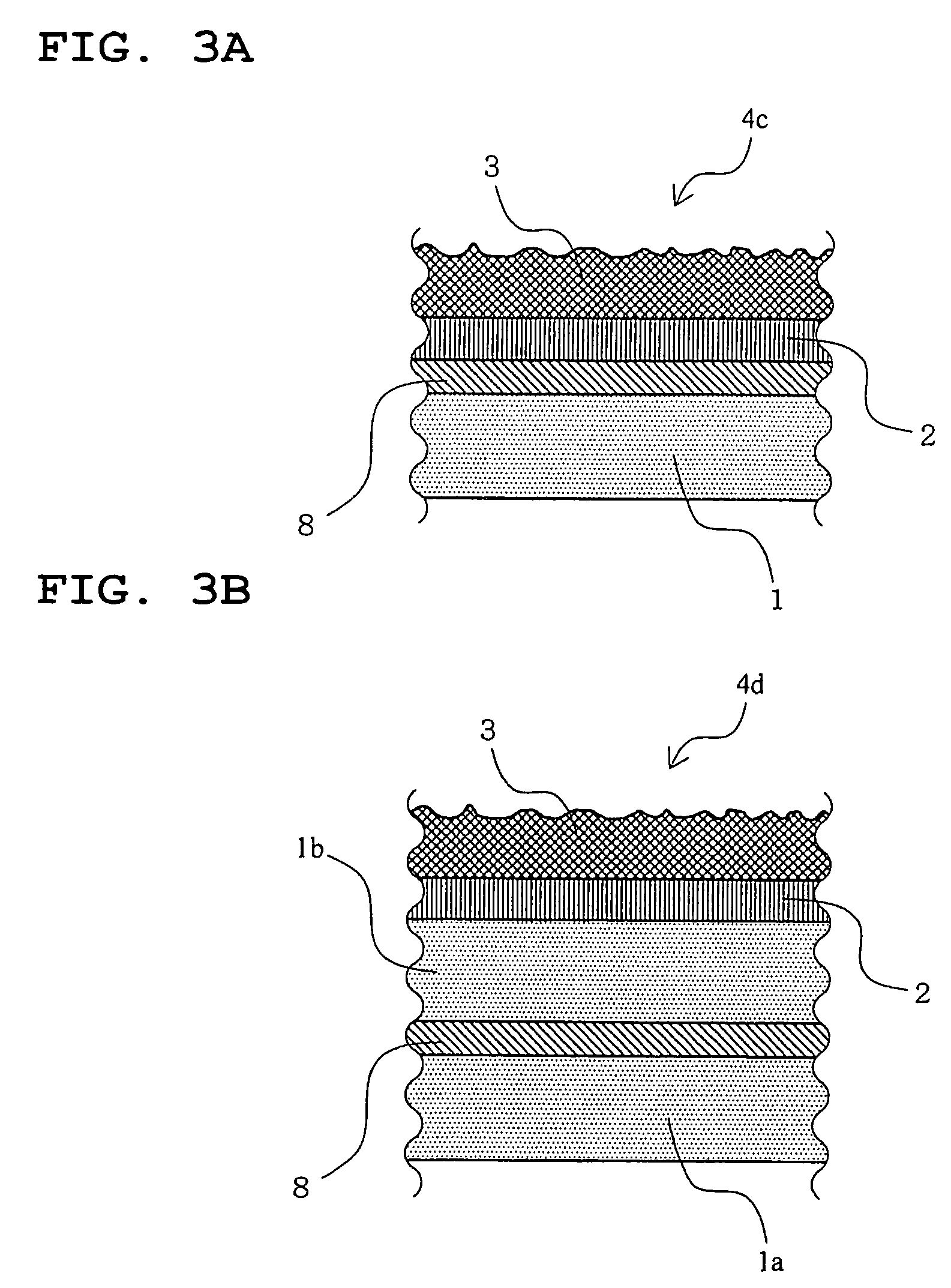

Film and mold release film

ActiveCN101479327AAvoid stickingPrevent outflowSynthetic resin layered productsPrinted circuit manufactureAdhesiveHeat resistance

A film that has a layer of specified 4-methyl-1-pentene copolymer and has a specified thickness buildup and thermal shrinkage coefficient. There is provided a film excelling in heat resistance and mold release properties, especially a film suitable for use as a mold release film applied in producing of a laminate according to pressure molding. When this film is used as a mold release film in the heating and pressurization steps for manufacturing of flexible printed boards, there can be prevented sticking of coverlay to metal sheet and outflow of adhesive leading to sticking to other members. Moreover, there can be avoided generation of voids in non-printed portions on the board, and contamination of exposed portions, such as terminal portions, of electric circuit by melting outflow of adhesive. Still further, wrinkling of the mold release film can be avoided, so that generation of voids due to follow failure of the mold release film can be avoided and that thus flexible printed boards with good appearance can be obtained.

Owner:MITSUI CHEM INC +1

Olefin-Based Polymers and Uses Thereof

ActiveUS20070249792A1Excellent in thermal resistance and various mechanical propertyFlexible coversWrappersHeat resistance4-Methyl-1-pentene

A novel olefin-based polymer has excellent thermal resistance, as well as excellent balance among various properties. The olefin-based polymer is an olefin-based polymer comprising 50 to 100% by weight of a constituent unit derived from 4-methyl-1-pentene, and 0 to 50% by weight of a constituent unit derived from at least one olefin selected from olefins having 2 to 20 carbon atoms except 4-methyl-1-pentene, and having the following properties: i) the diad isotacticity is 70% or greater, ii) the ratio (Mw / Mn) of the weight average molecular weight (Mw) to the number average molecular weight (Mn) as measured by gel permeation chromatography (GPC) is in the range of 1.0 to 3.5, and iii) the intrinsic viscosity [η] is 0.5 (dl / g) or greater.

Owner:MITSUI CHEM INC

Butyl rubber for wrapping capacitor case

The invention discloses a butyl rubber for wrapping a capacitor case, which is prepared from the following raw materials: butyl rubber (BBK232), LANXESS Deutschland 9650 ethylene propylene diene monomer, poly-4-methyl-1-pentylene, zinc oxide, nano fluorite powder, nano bentonite, attapulgite, anti-aging agent NBC, anti-aging agent OD, polyamide wax micropowder, accelerator TMTD, accelerator CZ, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, isopropyl tri(dioctylpyrophosphate)titanate, antioxidant 1035, carbon black N339, N660 carbon black 15-25, dibasic lead phosphite, tributyl citrate, stearic acid, coumarone, propanediol sebacate polyester, benzenesulfonyl hydrazide, ferrocene and modified kieselguhr. According to the reasonable raw material formula, the produced rubber has favorable comprehensive properties and strong binding property with metal; and the rubber has high mechanical properties, fatigue resistance, dynamic ozone resistance, aging resistance and the like, thereby providing a high-intensity protective function for the capacitor.

Owner:江苏南翔橡胶制品有限公司

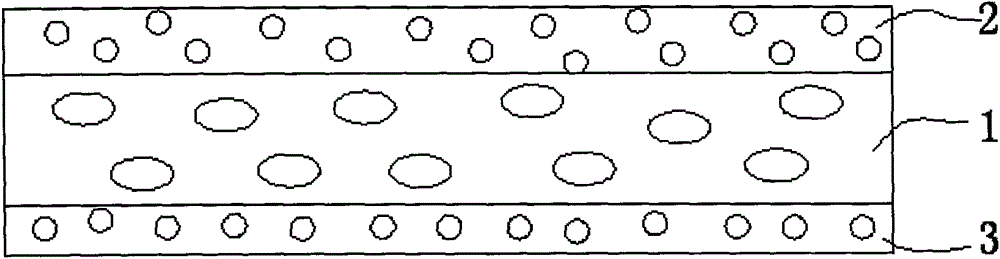

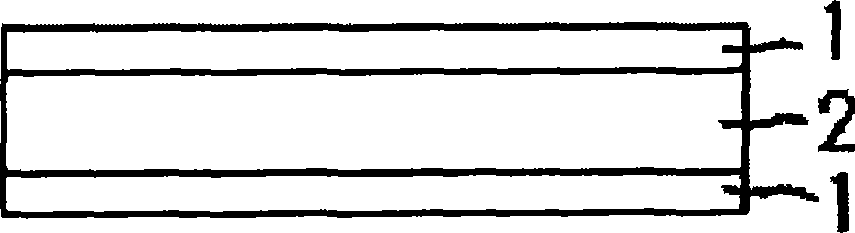

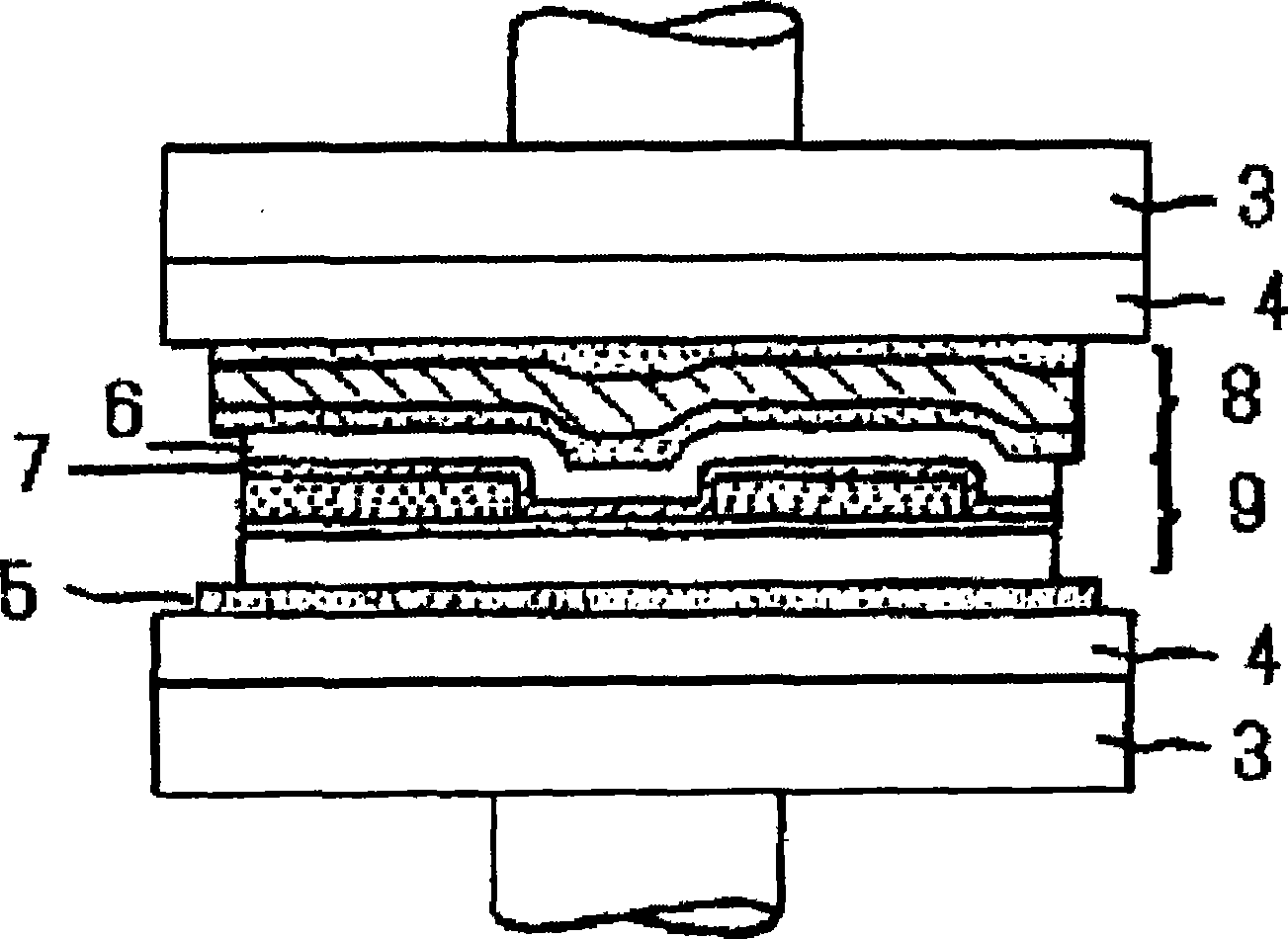

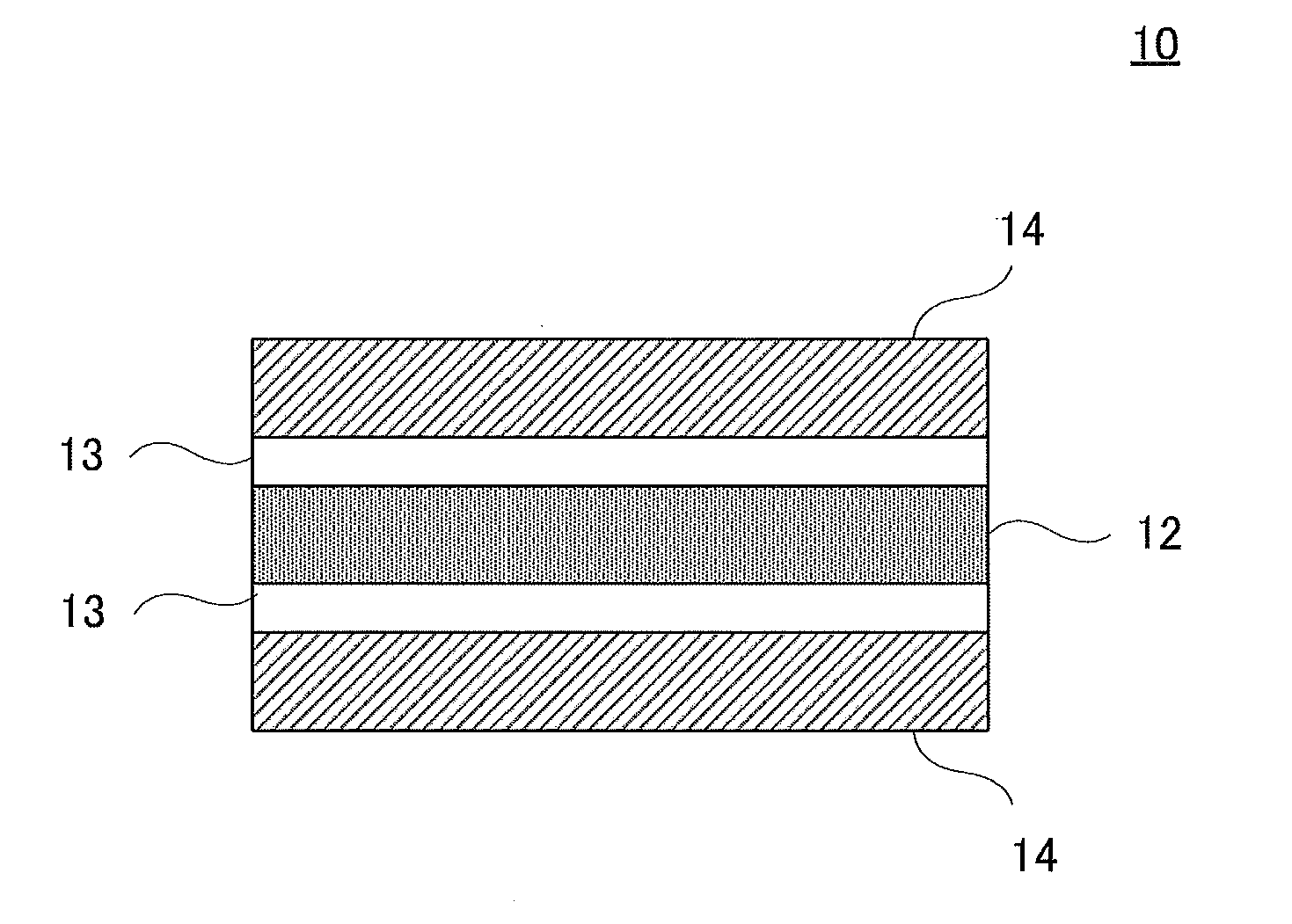

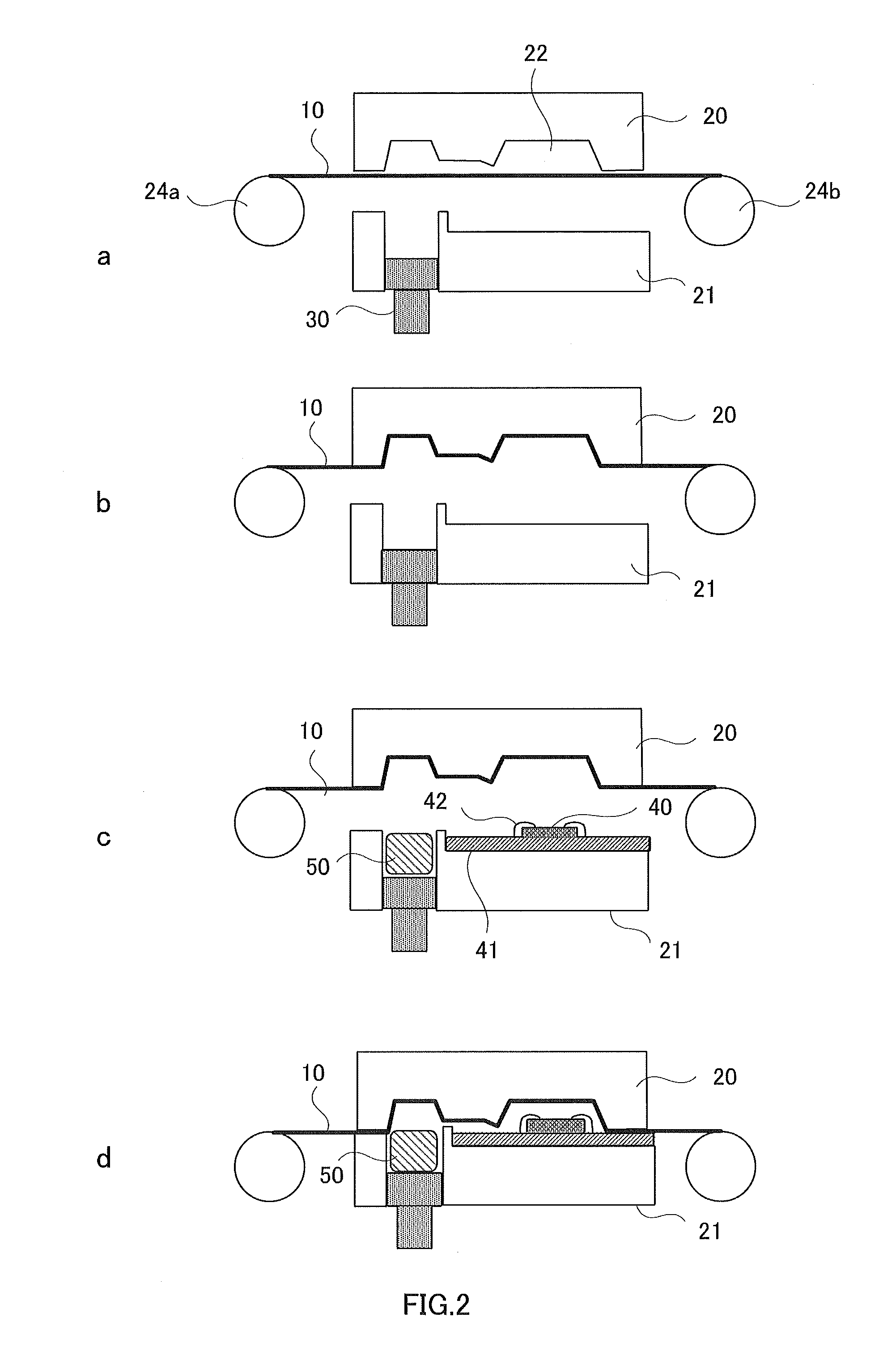

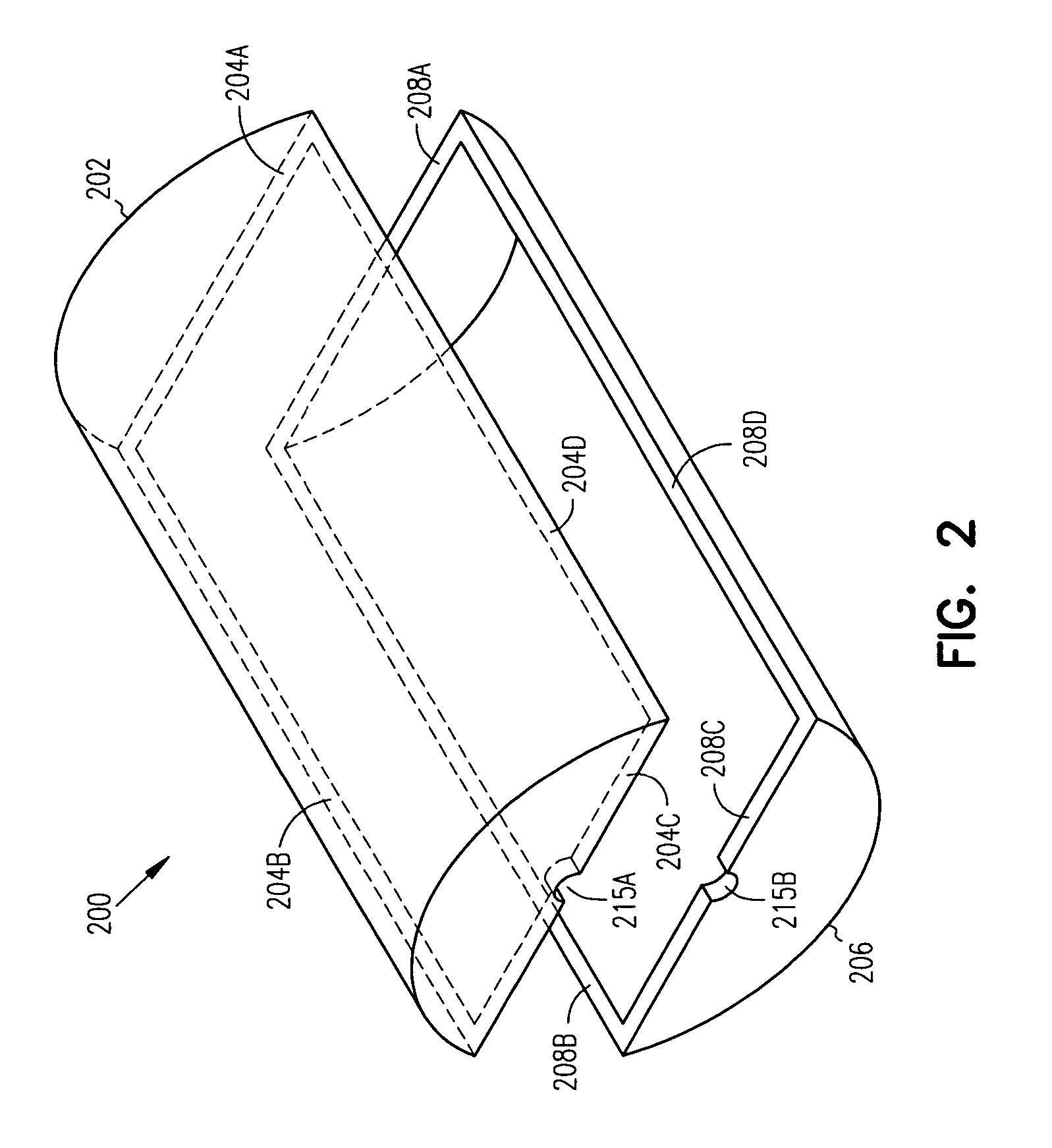

Mold release film for manufacturing semiconductor resin package and semiconductor resin package manufacturing method using same

InactiveUS20110133362A1Excellent semiconductor resin package releasabilityLess-prone to warpage and wrinklingSynthetic resin layered productsSolid-state devices4-Methyl-1-pentenePolyresin

Provided are: a mold release film, which has excellent mold releasability to a semiconductor resin package and does not easily generate warpage, wrinkles and the like; and a method for obtaining a semiconductor resin package having excellent dimensional accuracy by using such mold release film. The mold release film for manufacturing a semiconductor resin package has one or more base material layers (C), a pair of outermost layers (A) which sandwich the base material layers (C) and contain a 4-methyl-1-pentene polymer as a main component, and a pair of adhesive layers (B) which adhere together the base material layers (C) and the outermost layers (A).

Owner:MITSUI CHEM INC

Polyvinyl chloride tube containing modified attapulgite and preparing method thereof

The invention discloses a polyvinyl chloride (PVC) tube containing modified attapulgite and a preparing method thereof. The PVC tube containing the modified attapulgite is composed of raw materials comprising, based on the weight part ratio, 65-70 parts of SG-7 type PVC resin, 40-45 parts of high density polyethylene, 1-3 parts of poly-4-methyl-1-pentene, 2-4 parts of methyl methacrylate-butadiene-styrene terpolymer, 1.3-1.8 parts of alkylphenol ethoxylates, 2-3 parts of modified attapulgite, 25-30 parts of light calcium carbonate, 1-1.5 parts of dimethyl dimercapto acetic acid ethylhexyl acrylate stannum, 1.3-1.8 parts of diisobutyl phthalate, 0.9-1.1 parts of fungacetin, 1-2 parts of zinc sulfide and 0.4-0.6 part of methyl triethoxysilane. According to the PVC tube containing the modified attapulgite and the preparing method, a formulation is further optimized, the composition of the modified attapulgite is added in the formulation, and therefore dispersion of inorganic fillers is promoted and fluidity of PVC fusant is improved during the manufacturing process of the PVC tube, and furthermore tensile strength and breaking elongation are improved, toughness is good and hardness is low. In addition, the preparing method is simple and effectively applied to every walk of life.

Owner:ANHUI HAINA SICHUAN PLASTICS TECH

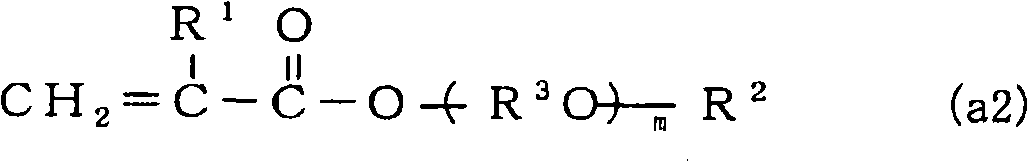

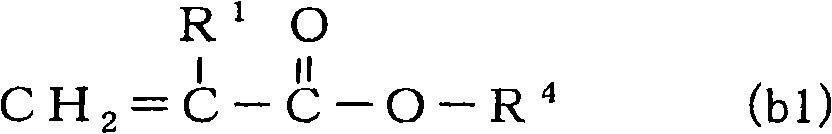

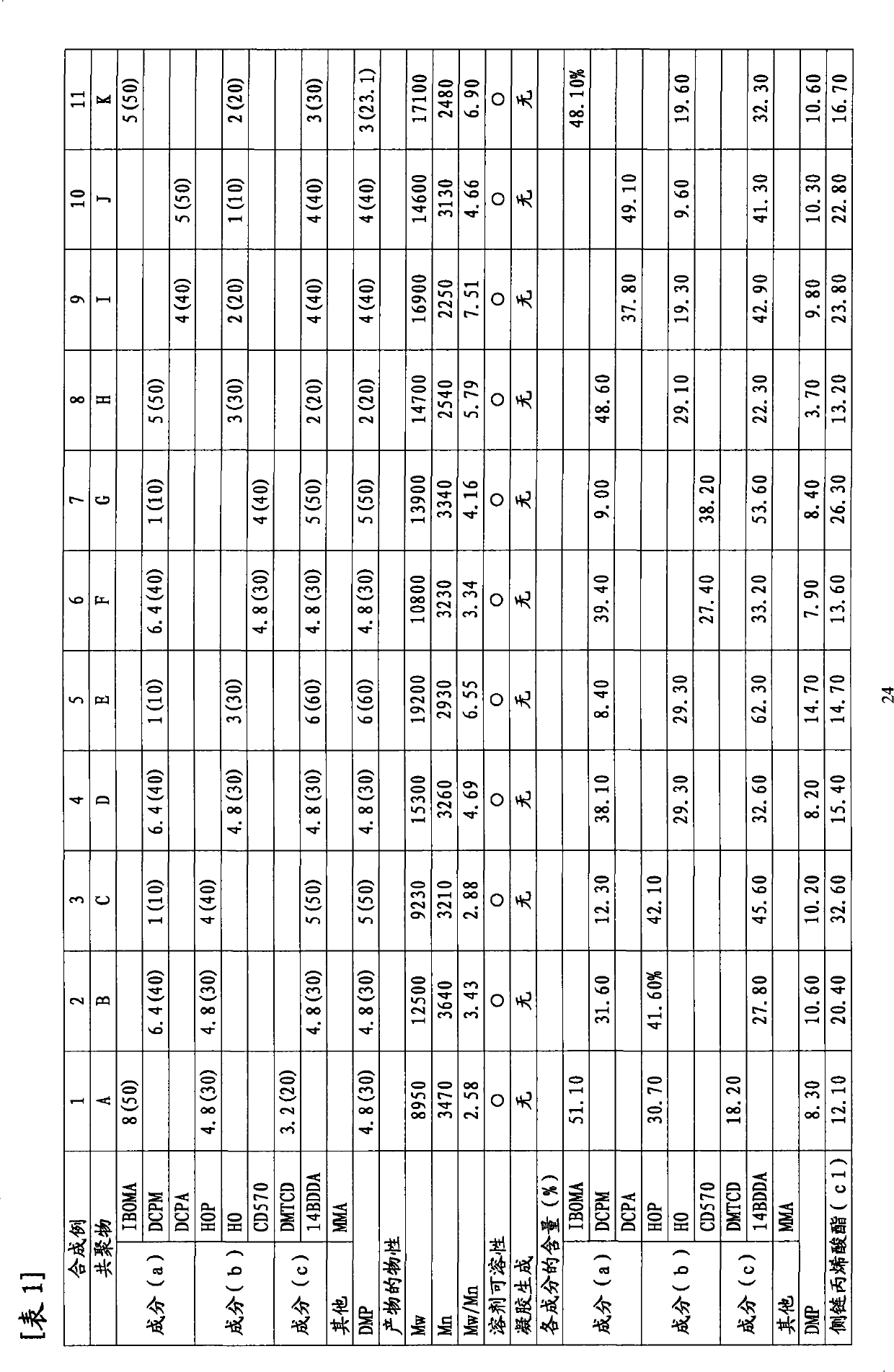

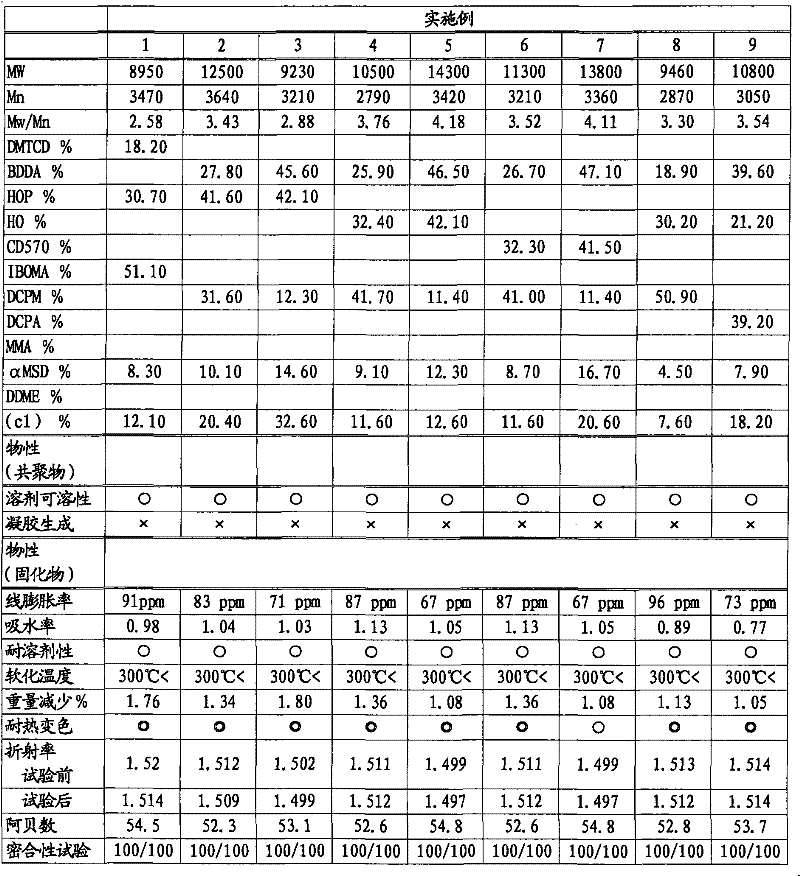

Curable resin composition and cured product thereof

A polyfunctional (methyl) acrylic ester composition is provided to have excellent optical properties of low color dispersibility and high optical transmissivity and to have excellent the balance of various properties needed for an optical lens or prism material. The polyfunctional (methyl) acrylic ester composition maintains excellent optical properties and does not cause reflective index differentiation even under severe and moisture use conditions. A curable resin composition comprises a soluble polyfunctional (meth)acrylic acid ester copolymer (A), and a monomer including at least one functional group containing polymerizable unsaturated double bond (B). The copolymer is manufactured through the copolymerization of monofunctional (meth)acrylic acid ester with a cycloaliphatic structure (a), a monofunctional (meth)acrylic acid ester with alcoholic hydroxy group(b), bifunctional (meth)acrylic acid ester(c), and 2,4-diphenyl-4-methyl-1-pentene(d). The content of component A is 1-70wt%.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

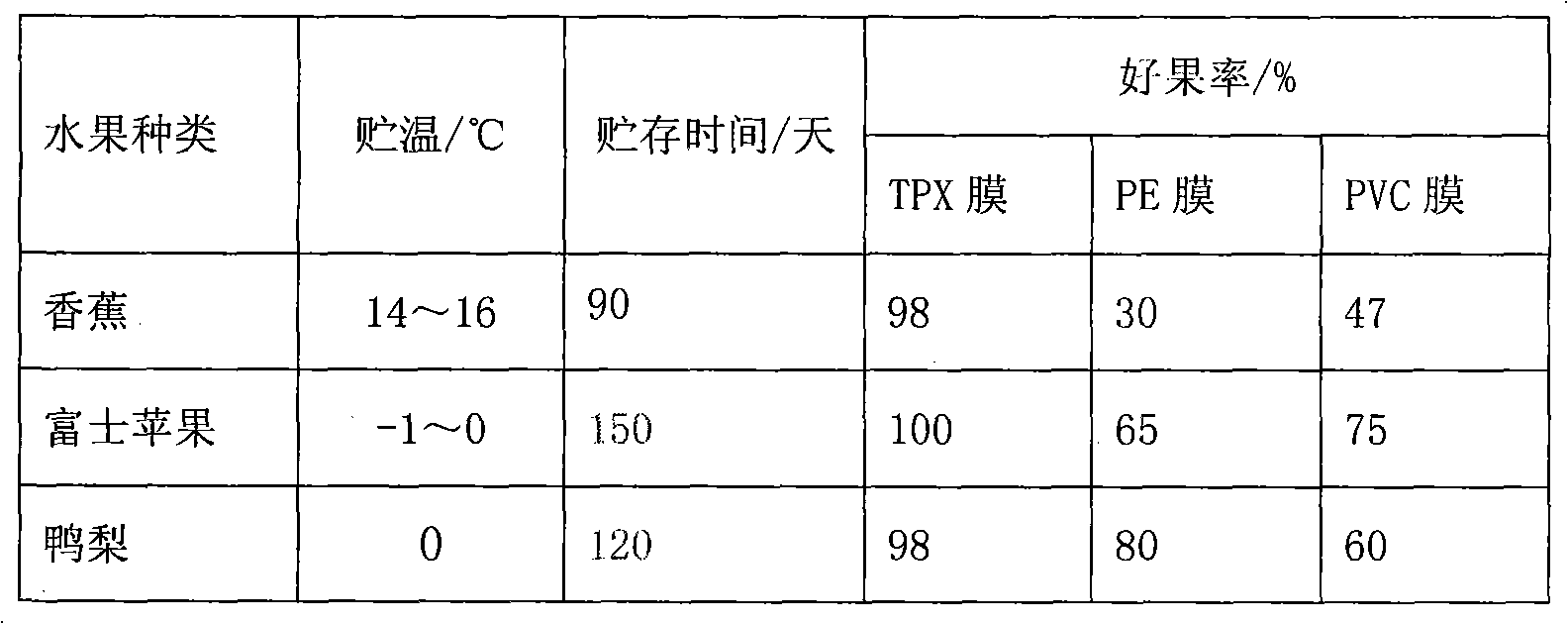

Method for preparing modified atmosphere fresh-keeping film for fruits and vegetables

InactiveCN102079834ASmooth outIncrease humidityFruit and vegetables preservationLow-density polyethyleneDecomposition

The invention relates to a method for preparing a modified atmosphere fresh-keeping film for fruits and vegetables. The fresh-keeping film is prepared by compounding an ethylene absorption and decomposition agent with gas absorbency and resin. The modified atmosphere fresh-keeping film comprises the following components in percentage by weight: 60 to 80 percent of poly(4-methyl-1-pentene) resin, 10 to 20 percent of low-density polyethylene, 2 to 5 percent of inorganic moisture-penetrating agent and 0.1 to 5 percent of ethylene absorption and decomposition agent. The modified atmosphere fresh-keeping film has the advantages of retarding the metabolic ageing of the fruits and the vegetables and prolonging the quality guarantee periods of the fruits and the vegetables, along with high carbon dioxide and oxygen permeability, high moisture-penetrability, ethylene absorption and decomposition functions, and relatively better fresh-keeping effects on the fruits such as bananas, apples and the like.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

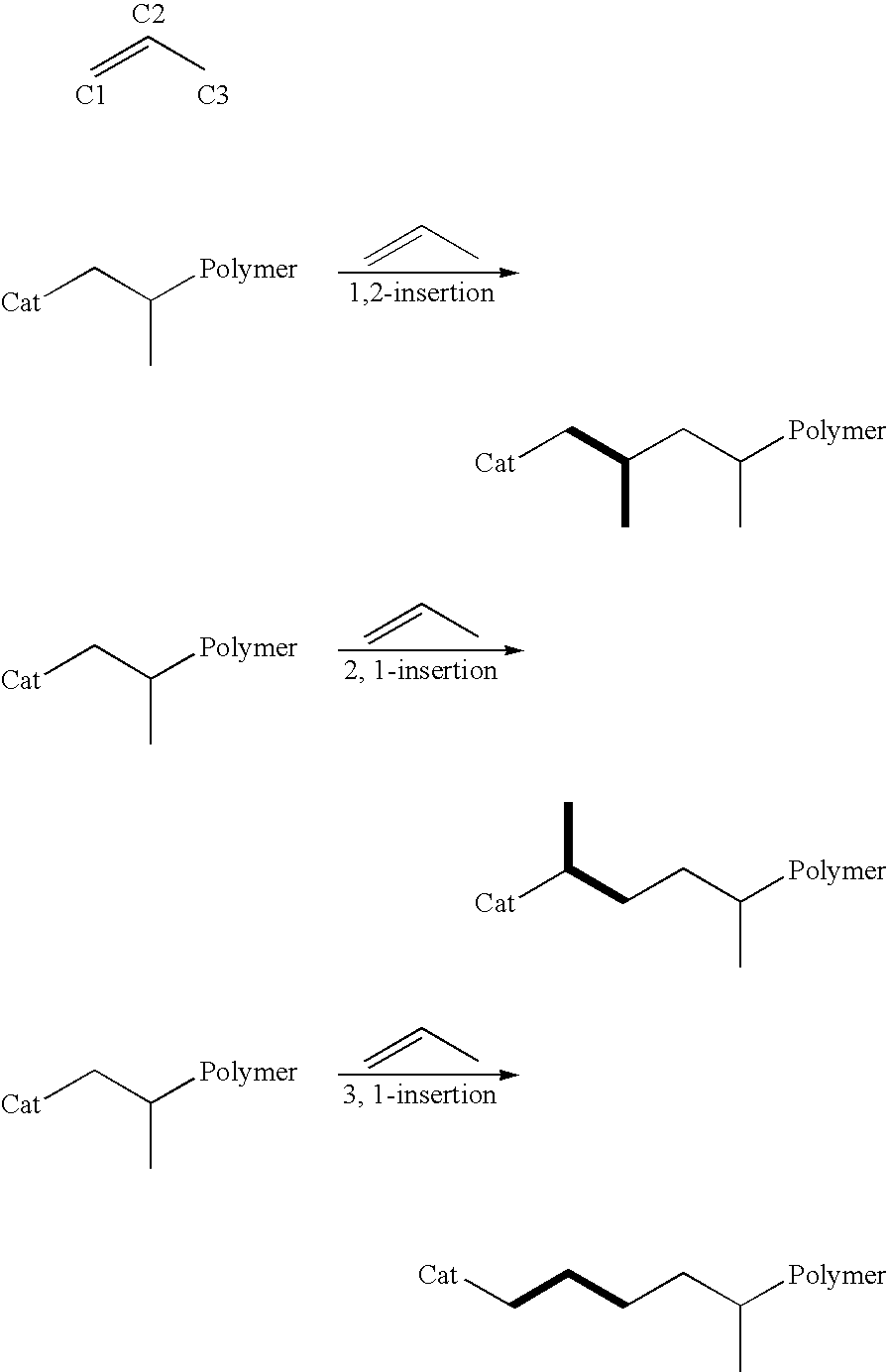

Catalyst composition comprising shuttling agent for regio-irregular multi-block copolymer formation

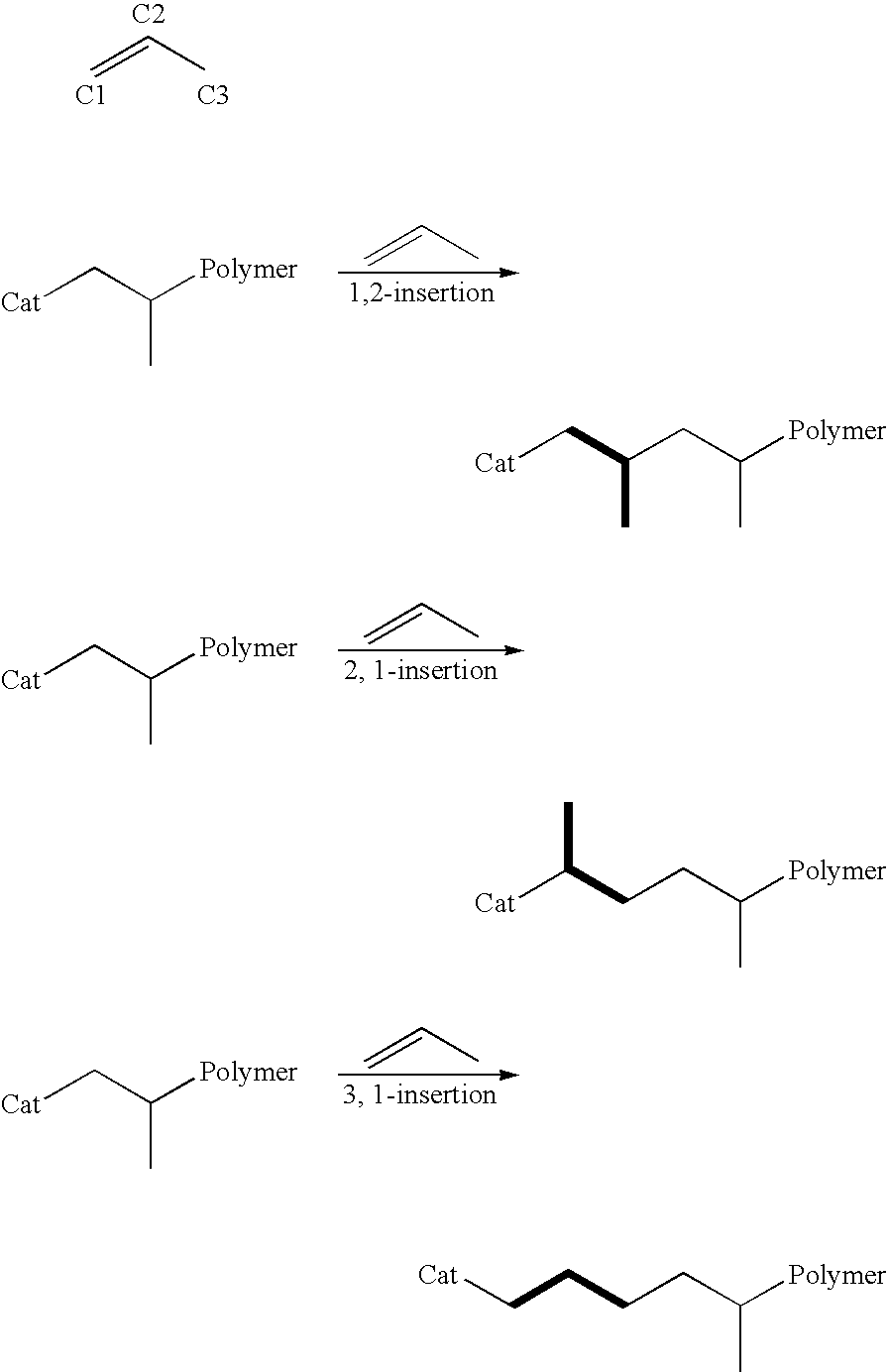

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks, are prepared by polymerizing propylene, 4-methyl-1-pentene, or another C4-8 α-olefin in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers having increased incidence of regio-irregular branching compared to the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Sterile, pyrogen-free, polymeric film-based heating bag

In one embodiment, there is a method for storing fluids in a bag that has an inner lining that is essentially sterilized and essentially free of pyrogen. The method comprises heating the bag that is comprised of a polymeric film to at least approximately 253° Celsius. The polymeric film includes a polymer selected from the group of poly(oxy-1,4-phenylene-oxy-1,4-phenylene-carbonyl-1,4-phenylene) (PEEK); polytetrafluoroethylene (PTFE); a perfluoroalkoxy (PFA) polymer; poly(tetrafluoroethylene-co-perfluoromethyl vinyl ether) (MFA); polyperfluoro(ethylene-co-propylene) (FEP); poly(ethylene-alt-chlorotrifluoroethylene) (ECTFE); poly(ethylene-co-tetrafluoroethylene) (ETFE); poly(vinylidene fluoride) (PDVF); tetrafluoroethylene-co-hexafluoropropylene-co-vinylidene fluoride terpolymer (THV); ultra-high molecular weight polyethylene (UHMW PE); (poly(bisphenol A-co-4-nitrophthalic anhydride-co-1,3-phenylenediamine) (PEI); poly(4-methyl-1-pentene) (PMP); and suitable mixtures thereof.

Owner:ADVANCED TECH MATERIALS INC +1

Polymer/carbon nanotube composites, methods of use and methods of synthesis thereof

InactiveUS20080306184A1Improve the immunityPrevent precipitationMaterial nanotechnologyElectric discharge heatingOrganic dyeSynthesis methods

Polymer / carbon nanotube composites including single-wall or multi-wall carbon nanotubes incorporated into the matrix of a polymer are provided. These composites can be used in environments exposed to galactic cosmic radiation. Accordingly, the composites are useful in deep space applications like space vehicles, space stations, personal equipment as well as applications in the biomedical arts and atom splitting research. The composites can be modified with organic dyes containing at least one phenyl ring and the resulting doped composite is useful as a radiation detector. The preferred polymer is poly(4-methyl-1-pentene). At low nanotube concentrations (i.e., about 0.5 wt % or less), the composites exhibit transparent optical qualities. At higher nanotube concentrations (i.e., about 0.6 wt % or more), the composites are non-transparent.

Owner:UNIV OF SOUTH FLORIDA

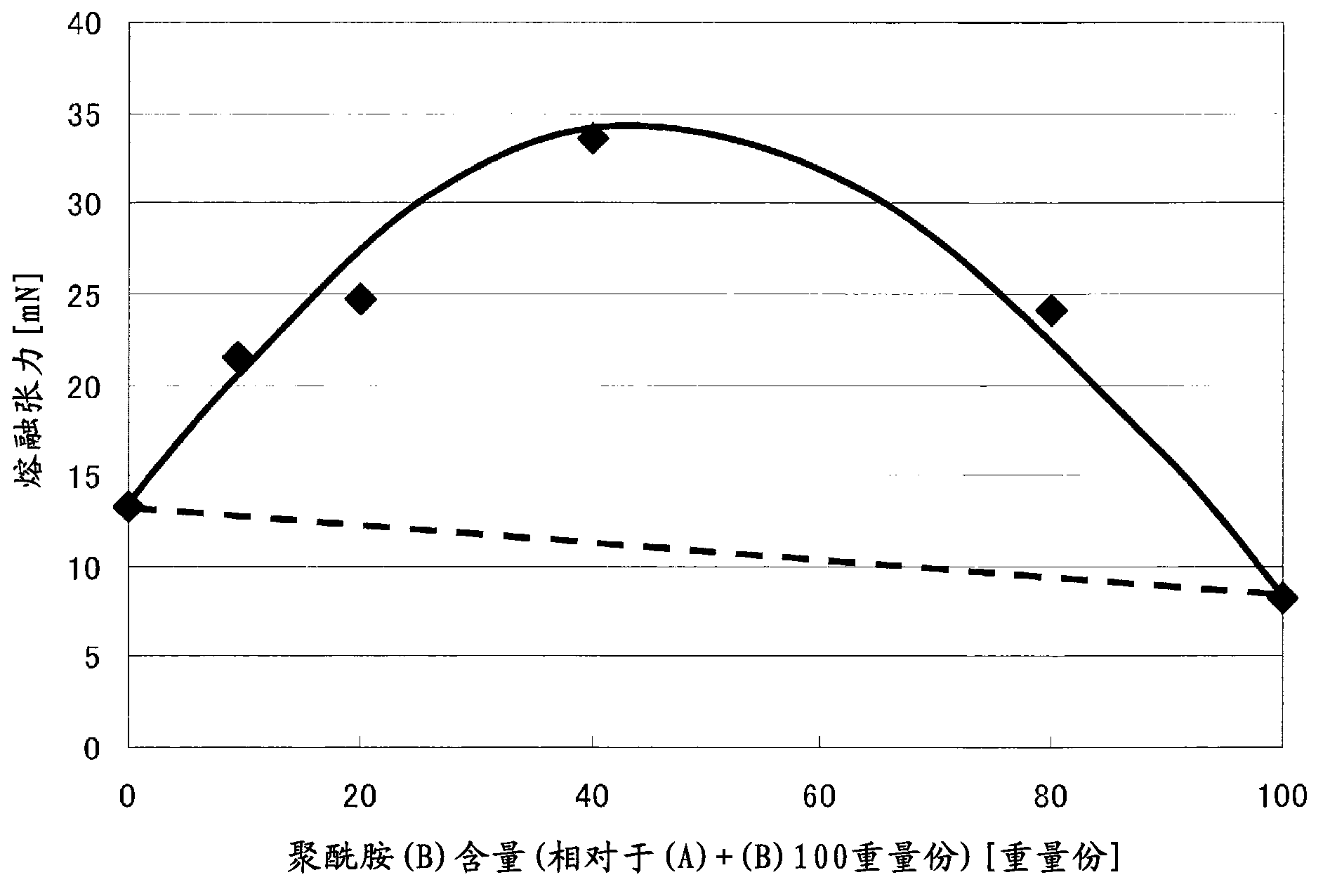

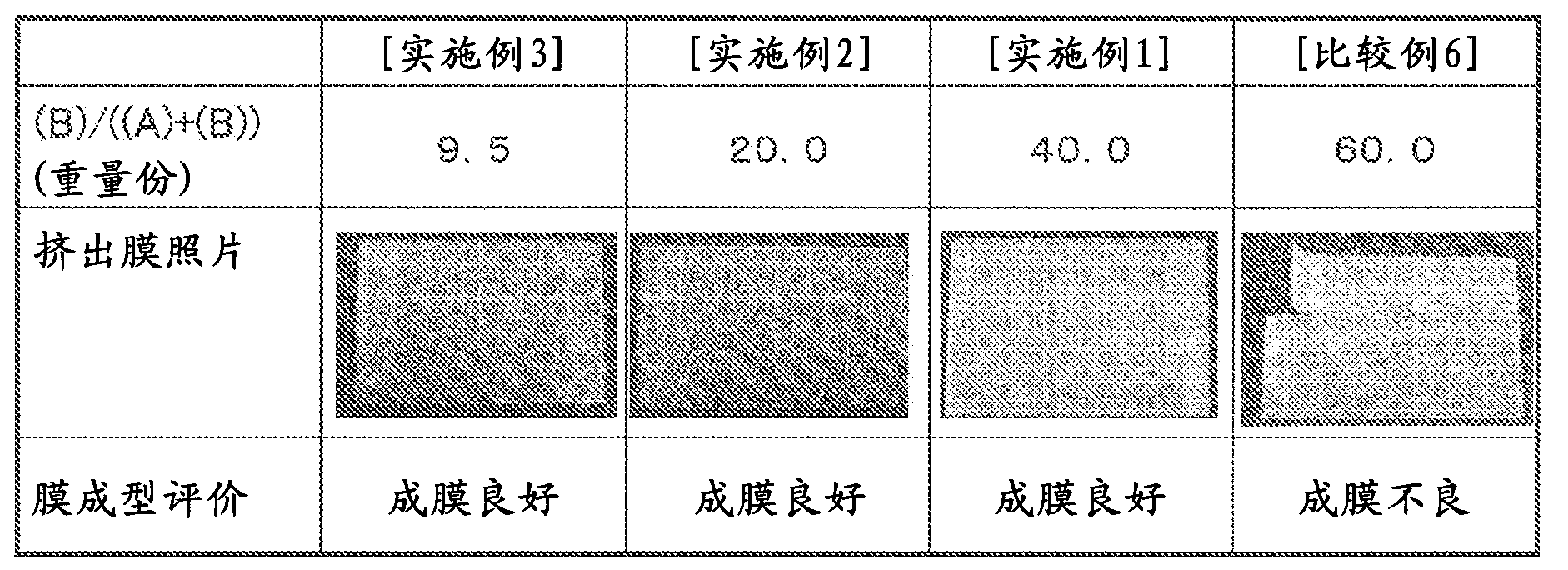

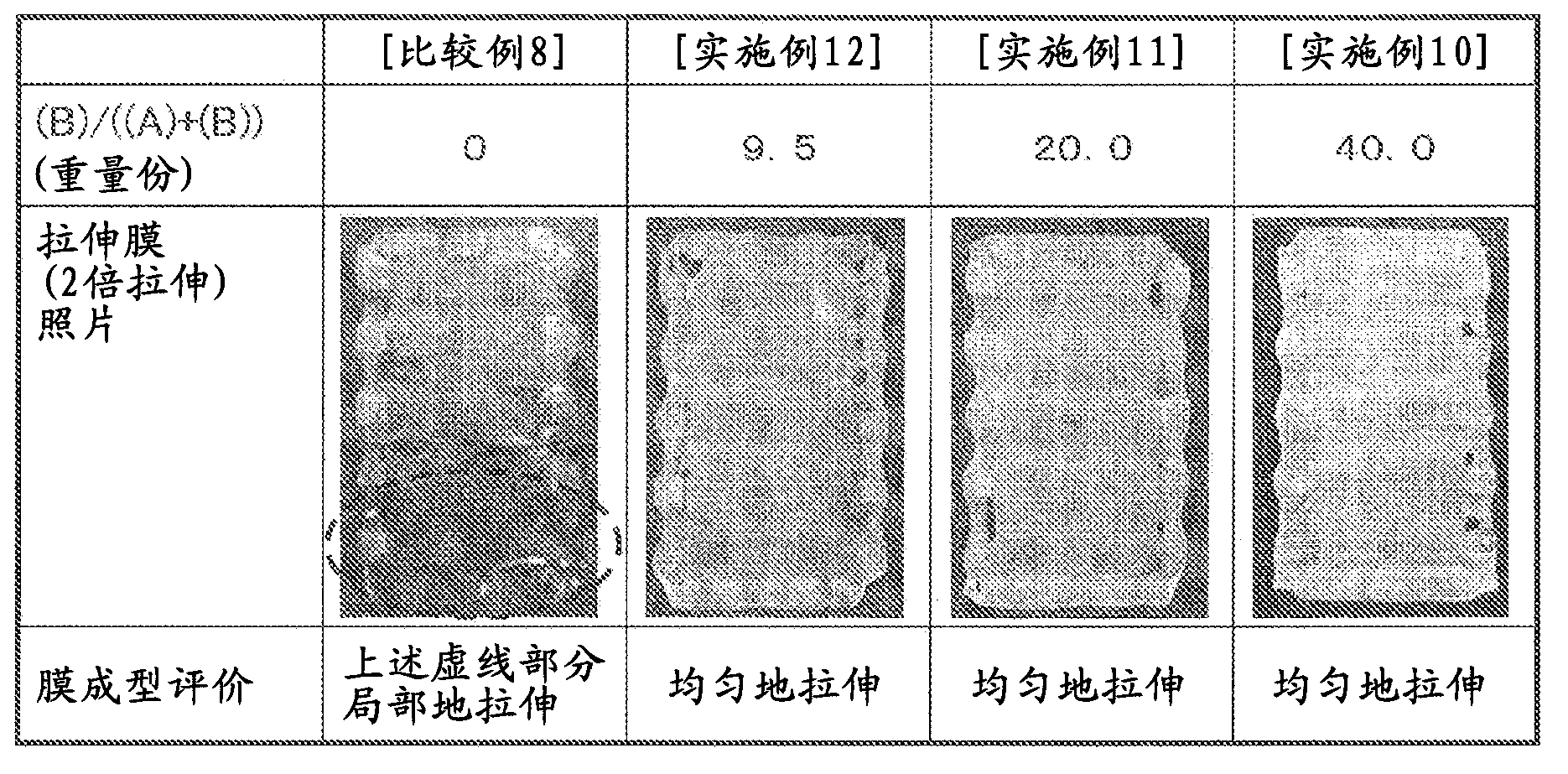

Poly-4-methyl-1-pentene based resin composition and molded products obtained from the composition

InactiveCN103189442ASmall water absorptionImprove tensile propertiesSynthetic resin layered productsThin material handlingPolyamide4-Methyl-1-pentene

To provide a poly-4-methyl-1-pentene based resin composition which exhibits improved film strength and improved moldability into various molded products while keeping the mold release properties and low water absorbency inherent in poly-4-methyl-1-pentene, and to provide molded products thereof. [Solution] The problem is solved by a poly-4-methyl-1-pentene based resin composition obtained by incorporating 0.1 to 30 parts by weight of a modified poly-4-methyl-1-pentene (C) prepared by grafting a monomer that contains an ethylenic unsaturated bond with 50 to 99 parts by weight of poly-4-methyl-1-pentene (A) and 1 to 50 parts by weight of a polyamide (B) (with the proviso that the sum of (A) and (B) is 100 parts by weight).

Owner:MITSUI CHEM INC

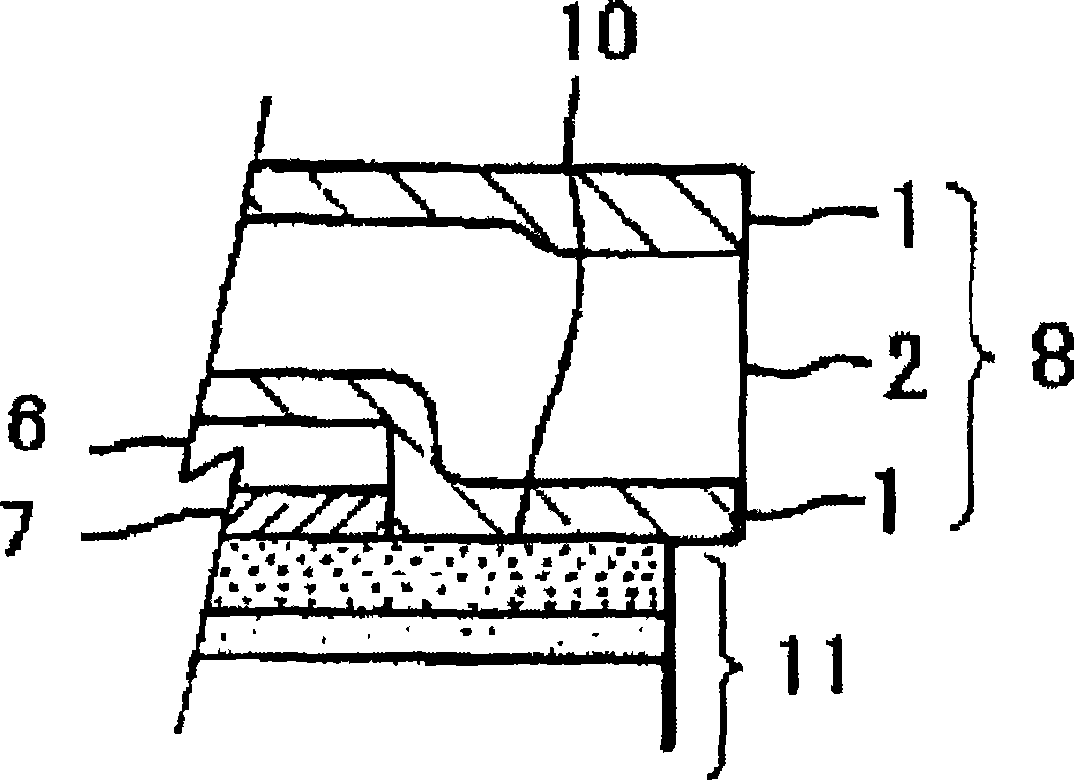

Multilayered 4-methyl-1 pentene copolymer film and process for producing the same

InactiveCN1392835AHighly integratedHigh precisionSynthetic resin layered productsLaminationPolymer scienceCopper foil

A multilayered 4-methyl-1-pentene copolymer film which is a laminate comprising layers (A) made of a 4-methyl-1-pentene copolymer and a layer (B) made of polypropylene or polyethylene and optionally further having one or more layers (C) made of an adhesive resin, the layers (A) being disposed respectively on both sides of the layer (B) optionally through the layers (C), the film having been monoaxially stretched at least 2 times or having been biaxially stretched at least 1.5 times in each of the machine and transverse directions. The multilayered film has satisfactory stretchability in production, has high rigidity, and has satisfactory releasability from blackened copper foils. It is suitable for use as a release film for MLB production.

Owner:MITSUI CHEM INC

Impact-resistance-modified polyvinyl chloride composite material

The invention discloses an impact-resistance-modified polyvinyl chloride composite material which is prepared from polyvinyl chloride, polyurethane, methyl methacrylate-butyl acrylate copolymer, polystyrene, polytetrafluoroethylene, nano graphite microsheets, magnesium hydroxide, zinc stannate, zinc borate, chlorinated paraffin, organic modified montmorillonite, poly-4-methyl-1-amylene, sulfonated polyethersulfone, methyl tin mercaptide, epoxy soybean oil, pentaerythritol, tri(2,4- di-tert-phenyl) phosphite, hexamethyl phosphoric triamide and triethyl phosphate. The impact-resistance-modified polyvinyl chloride composite material disclosed by the invention has the advantages of favorable toughness, excellent impact resistance, excellent processability, high flame retardancy and favorable antistatic property.

Owner:ANHUI LANTONG TECH CO LTD

Oil-proof anti-static polyvinyl chloride pipe

The invention discloses an oil-proof anti-static polyvinyl chloride pipe. The polyvinyl chloride pipe comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 10-30 parts of chloride polyethylene, 1-10 parts of ethylene-propylene-diene monomer, 1-3.5 parts of zinc oxide modified graphene oxide, 2-10 parts of zinc borate, 3-10 parts of aluminium hydroxide, 2-5 parts of coupling agent modified diatomite, 0.5-1.5 parts of antimony pent(iso-octyl thioglycollate), 1-2.5 parts of N-isopropyl-N'-phenyl p-phenylenediamine, 1-3 parts of calcium stearate, 1-2.5 parts of lanthanum stearate, 1-5 parts of epoxy soybean oil, 5-10 parts of polyethylene wax, 5-15 parts of poly-4-methyl-1-pentene, 0.5-2 parts of trioctyl trimellitate, and 1-5 parts of 2,4-bis(1,1-dimethylethyl)-pheno phosphite. The oil-proof anti-static polyvinyl chloride pipe disclosed by the invention has excellent oil resistance and static resistance, and is low in cost and good in processing property.

Owner:ANHUI LANTONG TECH CO LTD

Catalyst Composition Comprising Shuttling Agent for Regio-Irregular Multi-Block Copolymer Formation

ActiveUS20080262175A1Improve efficiencyHigh monomer conversion ratePolymer science4-Methyl-1-pentene

Copolymers, especially multi-block copolymer containing therein two or more segments or blocks, are prepared by polymerizing propylene, 4-methyl-1-pentene, or another C4-8 α-olefin in the presence of a composition comprising the admixture or reaction product resulting from combining: (A) a first metal complex olefin polymerization catalyst, (B) a second metal complex olefin polymerization catalyst capable of preparing polymers having increased incidence of regio-irregular branching compared to the polymer prepared by catalyst (A) under equivalent polymerization conditions, and (C) a chain shuttling agent.

Owner:DOW GLOBAL TECH LLC

Soluble polyfunctional (meth) acrylic ester copolymer, and method for production thereof, curable resin composition and cured product

The invention provides a copolymer which is excellent in optical characteristics, such as low in color dispersion and high in light transmission rate, has excellent balanced characteristics required by optical lenses and prism material, and can cause no refractive index change under real usage condition such as a damp and hot situation, and curable resin composition comprising the same, particularly to a soluble polyfunctional (meth) acrylic ester copolymer and a curable resin composition comprising the same. The soluble polyfunctional (meth) acrylic ester copolymer is obtained by conducting copolymerization on a single functional (meth) acrylic ester (a) containing a fat ring type structure, a single functional (meth) acrylic ester (b) containing a hydroxyl group, a bifunctional (meth) acrylic ester (c) and a 2, 4-diphenyl-methyl-1-pentene (d). A side chain of the soluble polyfunctional (meth) acrylic ester copolymer comprises a reactive (meth) acrylic ester from (c), and the end of the soluble polyfunctional (meth) acrylic ester copolymer comprises a structural unit from (d).

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com