Film and mold release film

A technology of methyl and pentene, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problem of large thermal expansion coefficient of release film, wrinkles on the surface of release film, circuit and mold release Solve problems such as film voids, and achieve the effects of excellent heat resistance and mold release, improvement of poor appearance, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

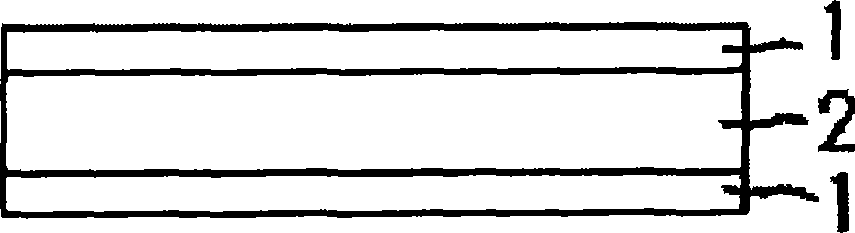

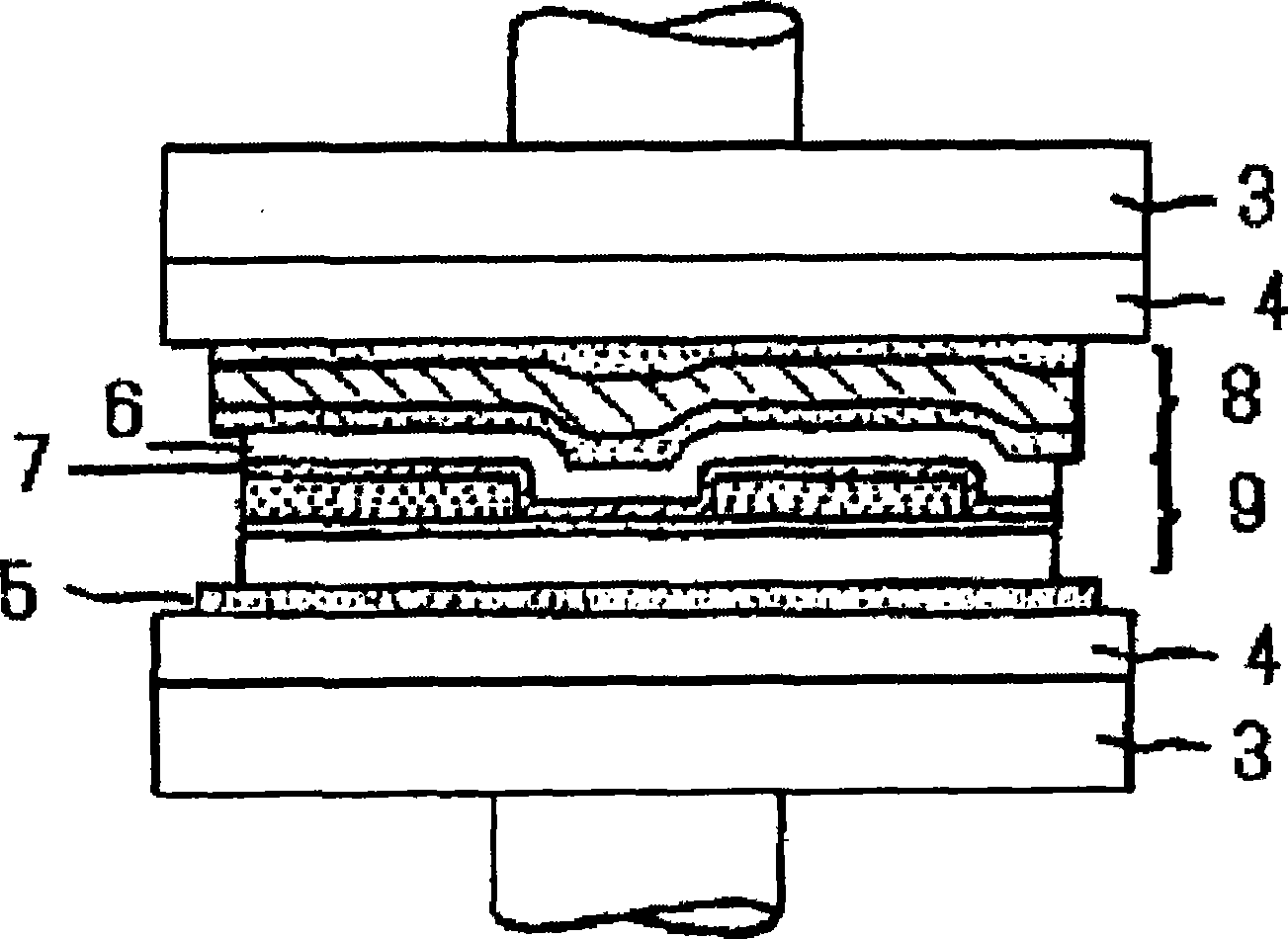

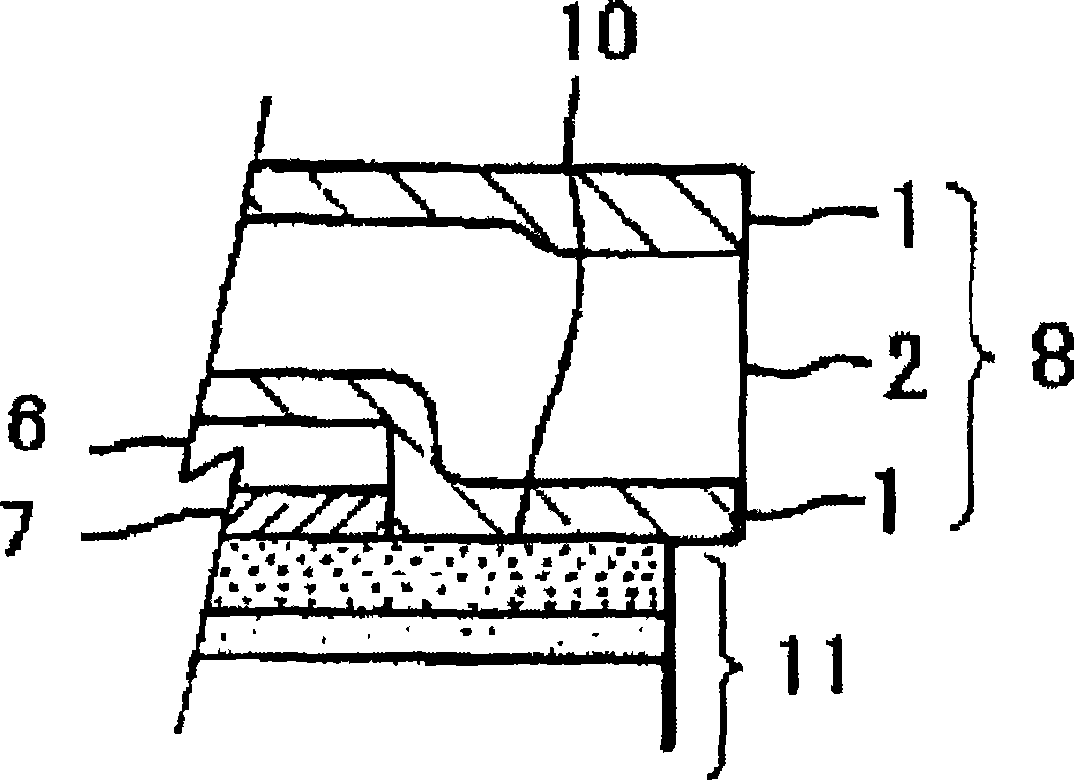

[0164] Films were produced using a multi-manifold type extruder with a three-layer coextrusion T-die. Using the first extruder and the third extruder, (A1) 4-methyl-1-pentene copolymer (1-decene content: 2.4% by mass, MFR: 25g / 10 points, melting point: 233°C) plasticizing. In addition, (B1) propylene·1-butene copolymer (density: 0.89 g / cm 3 , MFR: 30g / 10 minutes, melting point: 110°C, Vicat softening temperature: 78°C, 1-butene content: 20mol%) plasticized.

[0165] With A1 as the layer (A) and B1 as the layer (B), the composite of layer (A) / layer (B) / layer (A) is performed in a co-extrusion T-die. Furthermore, while pulling (20 m / min) this composite compound with a roll, the multilayer film which consists of three layers was manufactured.

[0166]Then, the surface of the obtained multilayer film was embossed with two embossing rolls whose average roughness (Ra) was 25 micrometers. The roll temperature was 130°C, and the embossing speed was 20 m / min. The peripheral speed ...

Embodiment 2

[0171] In addition to using (B2) ethylene-ethyl acrylate copolymer (MFR: 27 g / 10 minutes, melting point: 90° C., Vicat softening temperature: 70° C., ethyl acrylate content: 15 mol %) instead of B1, in addition, press The conditions shown in Table 1 were the same as in Example 1 to produce a multilayer film.

[0172] Then, the multilayer film was heated and pressed under the same conditions as in Example 1 to bond the overcoat layer to the surface of the circuit formed on the substrate.

[0173] Evaluation was performed in the same manner as in Example 1, and the evaluation results are shown in Table 1.

Embodiment 3

[0175] Use (B3) propylene·1-butene·4-methyl-1-pentene copolymer (propylene content: 36 mol%, 1-butene content 14 mol%, 4-methyl-1-pentene content: 50 mol%, density: 0.880g / cm 3 , MFR: 27g / 10 minutes, Vicat softening temperature: 80°C) 50% by mass and linear low-density polyethylene (density: 0.92g / cm 3 , MFR: 15g / 10 minutes, Vicat softening temperature: 100°C) 50 mass% blend (MFR: 20g / 10 minutes, Vicat softening temperature: 85°C) instead of B1, in addition, according to Table 1 The conditions shown and the same procedure as in Example 1 produced a multilayer film.

[0176] Then, the multilayer film was heated and pressed under the same conditions as in Example 1 to bond the overcoat layer to the surface of the circuit formed on the substrate.

[0177] Evaluation was performed in the same manner as in Example 1, and the evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com