Butyl rubber for wrapping capacitor case

A technology of butyl rubber and capacitor casing, applied in the field of rubber materials, can solve the problems of not being effectively guaranteed, affecting the normal operation of capacitors, and wasting resources, etc., achieving strong adhesion, saving costs, and increasing service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

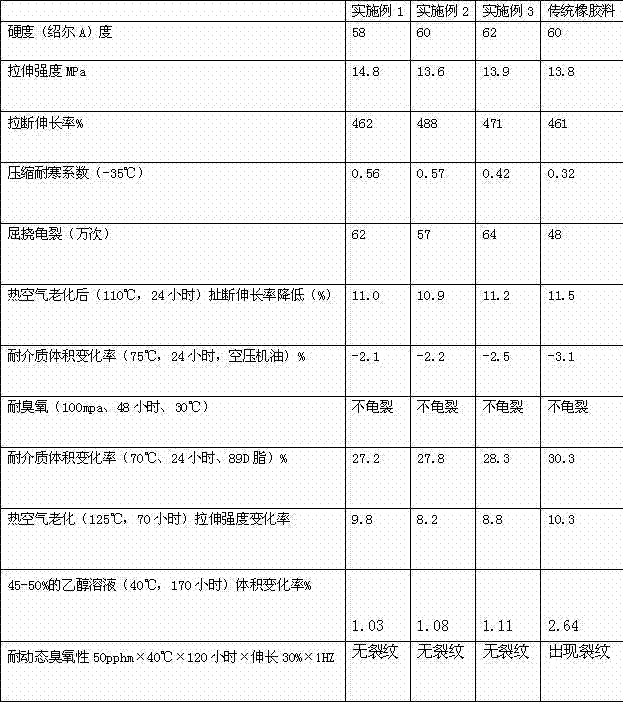

Examples

Embodiment 1

[0015] A butyl rubber material for wrapping capacitor shells, the capacitor shell adopts a metal mesh inner skeleton, and the rubber material is wrapped on the outside, and the rubber material is composed of the following raw materials in parts by weight:

[0016] Butyl rubber (BBK232) 135, German LANXESS 9650 EPDM rubber 15, poly-4-methyl-1-pentene 8, zinc oxide 3, nano-fluorite powder 45, nano-bentonite 35, attapulgite 20, Antiaging agent NBC2, antiaging agent OD 2, polyamide wax powder 8, accelerator TMTD2, accelerator CZ 2, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane 5, isopropyltri( Dioctyl pyrophosphate acyloxy) titanate 3, antioxidant 1035 2, carbon black N339 20, N660 carbon black 15-25, dibasic lead phosphite 2, tributyl citrate 8, stearic acid 8. Coumarone 5, propylene glycol sebacate polyester 8, benzenesulfonyl hydrazide 2, ferrocene 2, modified diatomite 3;

[0017] The preparation method of the modified diatomite is as follows: diatomite is soaked with 15% hy...

Embodiment 2

[0021] Rubber compound is made up of the raw material of following weight portion:

[0022] Butyl rubber (BBK232) 140, German LANXESS 9650 EPDM rubber 12, poly-4-methyl-1-pentene 6, zinc oxide 3, nano-fluorite powder 42, nano-bentonite 31, attapulgite 20, Antiaging agent NBC2, antiaging agent OD 2, polyamide wax powder 8, accelerator TMTD2, accelerator CZ 2, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane 5, isopropyltri( Dioctyl pyrophosphate acyloxy) titanate 3, antioxidant 1035 2, carbon black N339 20, N660 carbon black 15-25, dibasic lead phosphite 2, tributyl citrate 8, stearic acid 6. Coumarone 5, propylene glycol sebacate polyester 6, benzenesulfonyl hydrazide 2, ferrocene 2, modified diatomite 3;

Embodiment 3

[0024] Rubber compound is made up of the raw material of following weight portion:

[0025] Butyl rubber (BBK232) 143, German LANXESS 9650 EPDM rubber 14, poly-4-methyl-1-pentene 7, zinc oxide 2, nano-fluorite powder 44, nano-bentonite 32, attapulgite 18, Antiaging agent NBC2, antiaging agent OD 2, polyamide wax powder 8, accelerator TMTD2, accelerator CZ 2, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane 5, isopropyltri( Dioctyl pyrophosphate acyloxy) titanate 3, antioxidant 1035 2, carbon black N339 20, N660 carbon black 15-25, dibasic lead phosphite 2, tributyl citrate 8, stearic acid 8, coumarone 5, propylene glycol sebacate polyester 6, benzenesulfonyl hydrazide 2, ferrocene 2, modified diatomite 3; (the processing method of embodiment 2 and 3 is the same as embodiment 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com