Auto-inflatable tire repairing liquid and preparation method thereof

A technology of automatic inflation and tire sealant, applied in adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of dryness or freezing in cold weather, difficulty in achieving market development, and loss of leakage repairing effect To achieve the effect of improving the anti-icing ability, good mechanical and chemical stability, and accelerating the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

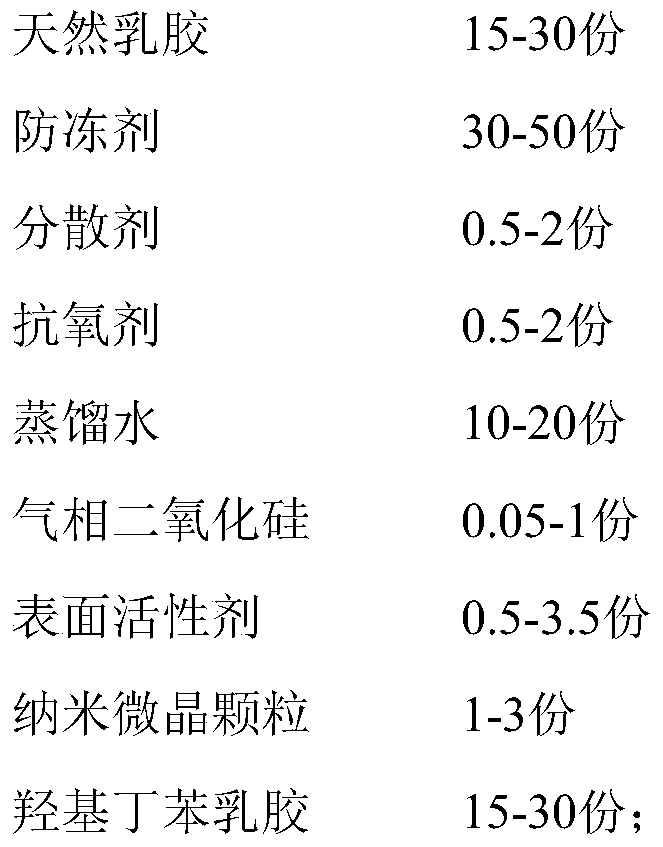

[0032] A self-inflating tire sealant, comprising the following raw materials in parts by weight:

[0033]

[0034]

[0035] The solid content of the natural latex is 50%.

[0036] Each part of the nanocrystalline particles is a mixture of microcrystalline cellulose 102 and nano carbon powder in a weight ratio of 0.8:0.4.

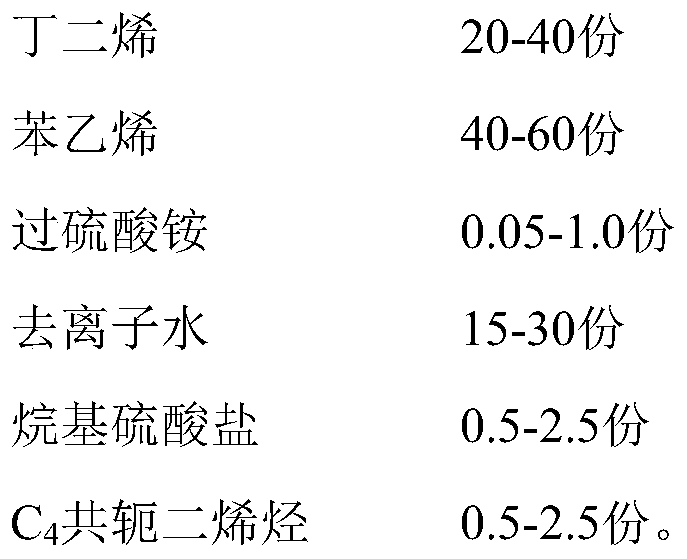

[0037] Every part of said hydroxybutadiene latex comprises the raw material of following parts by weight:

[0038]

[0039] Described hydroxybutadiene latex is made by following method:

[0040] 1) According to parts by weight, disperse butadiene and ammonium persulfate into deionized water, heat to 30°C and stir until uniform, to obtain mixture A, set aside;

[0041] 2) Transfer the mixture A to a vacuum reaction device, heat it to 60°C for 30 minutes, and then add the alkyl sulfate and C 4 The conjugated diene is added therein, and the temperature is raised to 80° C. to continue the vacuum polymerization reaction for 1 hour, and the hydroxybuta...

Embodiment 2

[0052] A self-inflating tire sealant, comprising the following raw materials in parts by weight:

[0053]

[0054] The solid content of the natural latex is 55%.

[0055] Each part of the nanocrystalline particles is a mixture of microcrystalline cellulose 102 and nano carbon powder in a weight ratio of 0.9:0.5.

[0056] Every part of said hydroxybutadiene latex comprises the raw material of following parts by weight:

[0057]

[0058] Described hydroxybutadiene latex is made by following method:

[0059] 1) According to parts by weight, disperse butadiene and ammonium persulfate into deionized water, heat to 35°C and stir until uniform, to obtain mixture A, set aside;

[0060] 2) Transfer the mixture A to a vacuum reaction device, heat it to 65°C and keep it for 38min, then put the alkyl sulfate and C 4 The conjugated diene is added therein, and the temperature is raised to 85° C. to continue vacuum polymerization for 1.5 hours, and the hydroxybutadiene latex is obta...

Embodiment 3

[0071] A self-inflating tire sealant, comprising the following raw materials in parts by weight:

[0072]

[0073]

[0074] The solid content of the natural latex is 60%.

[0075] Each part of the nanocrystalline particles is a mixture of microcrystalline cellulose 102 and nano carbon powder in a weight ratio of 1.0:0.6.

[0076] Every part of said hydroxybutadiene latex comprises the raw material of following parts by weight:

[0077]

[0078] Described hydroxybutadiene latex is made by following method:

[0079] 1) According to parts by weight, disperse butadiene and ammonium persulfate into deionized water, heat to 40°C and stir until uniform, to obtain mixture A, set aside;

[0080] 2) Transfer the mixture A to a vacuum reaction device, heat it to 70°C for 45 minutes, and then add the alkyl sulfate and C 4 The conjugated diene is added therein, and the temperature is raised to 90° C. to continue the vacuum polymerization reaction for 2 hours, and the hydroxybut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com