Calendering grass green rubber foxing adhesive for wear-resistant liberation shoes as well as preparation method and application thereof

A technology of rubber strip glue and Jiefang shoes, which is applied in the field of rubber material preparation, can solve problems such as unreasonable reinforcement system, large temperature fluctuation of rubber material performance, and unstable process performance, so as to improve scorch resistance and durability. Inflection performance, improved molding pass rate and service life, rubber quality and stable process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

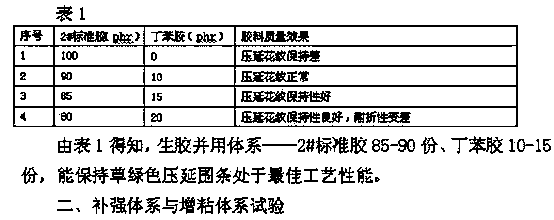

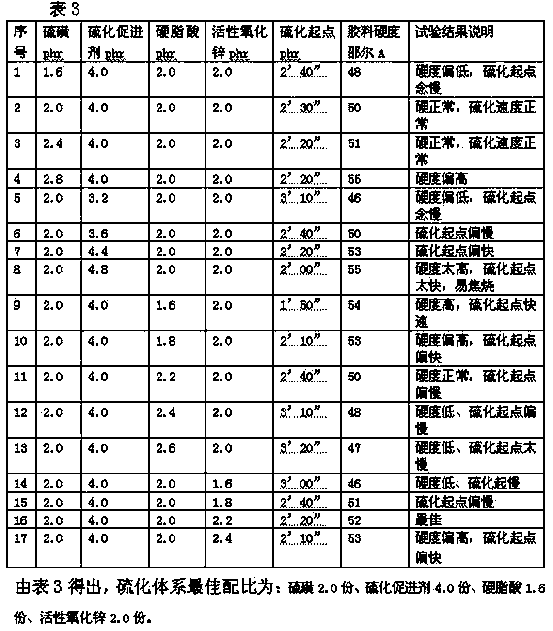

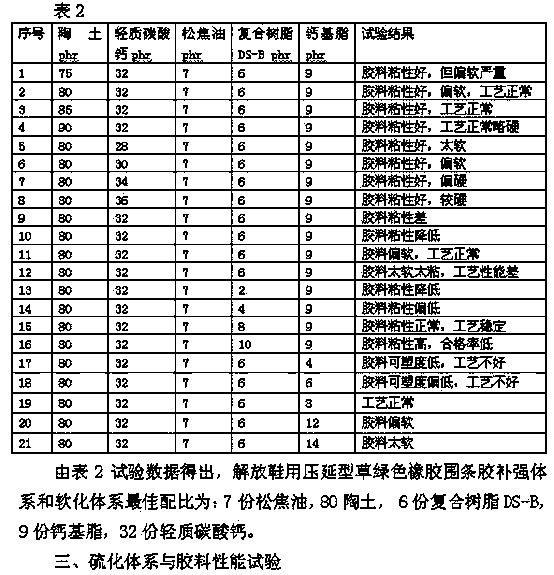

[0021] Embodiment 1 of the present invention: wear-resistant type Jiefang shoes use calendered grass-green rubber enclosure glue, calculated in parts by weight, including 90 parts of 2# standard glue, 10 parts of styrene-butadiene rubber, 15 parts of high styrene, 2.2 parts Sulfur, 4 parts of vulcanization accelerator, 2 parts of stearic acid, 2 parts of active zinc oxide, 7 parts of pine tar, 65 parts of clay, 3.8 parts of anti-aging agent, 6 parts of composite resin DS-B, 9 parts of 3# calcium base grease, 32 parts of light calcium carbonate and 5 parts of grass green masterbatch; every 5 parts of vulcanization accelerator is composed of 3 parts of accelerator DM, 1.5 parts of accelerator M and 0.5 parts of accelerator DS; every 3.8 parts of anti-aging agent is composed of 3 parts of anti-aging agent Composed of CD and 0.8 parts of anti-aging agent KY-405L.

[0022] The preparation method of the calendered grass-green rubber enclosure glue for wear-resistant Jiefang shoes co...

Embodiment 2

[0025] Embodiment 2 of the present invention: wear-resistant type Jiefang shoes use calendered grass-green rubber enclosure glue, calculated according to parts by weight, including 90 parts of 2# standard glue, 10 parts of styrene-butadiene rubber, 15 parts of high styrene, 2 parts Sulfur, 4 parts of vulcanization accelerator, 2 parts of stearic acid, 2.2 parts of active zinc oxide, 7 parts of pine tar, 65 parts of clay, 3 parts of antioxidant, 5 parts of composite resin DS-B, 8 parts of 3# calcium base grease, 30 parts of light calcium carbonate and 6 parts of grass green masterbatch; every 5 parts of vulcanization accelerator is composed of 3 parts of accelerator DM, 1.5 parts of accelerator M and 0.5 parts of accelerator DS; every 3.8 parts of anti-aging agent is composed of 3 parts of anti-aging agent Composed of CD and 0.8 parts of anti-aging agent KY-405L.

[0026] The preparation method is the same as in Example 1.

Embodiment 3

[0027] Embodiment 3 of the present invention: wear-resistant type Jiefang shoes use calendered grass-green rubber enclosure glue, calculated in parts by weight, including 85 parts of 2# standard glue, 15 parts of styrene-butadiene rubber, 15 parts of high styrene, and 2.4 parts Sulfur, 6 parts of vulcanization accelerator, 1.8 parts of stearic acid, 1.8 parts of active zinc oxide, 8 parts of pine tar, 70 parts of clay, 4 parts of anti-aging agent, 6 parts of composite resin DS-B, 9 parts of 3# calcium base grease, 34 parts of light calcium carbonate and 4 parts of grass green masterbatch; every 5 parts of vulcanization accelerator consists of 3 parts of accelerator DM, 1.5 parts of accelerator M and 0.5 parts of accelerator DS; every 3.8 parts of anti-aging agent consists of 3 parts of anti-aging agent Composed of CD and 0.8 parts of anti-aging agent KY-405L.

[0028] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com