Graphene-carbon nanotube synergistic high-electrical-property semiconductive shielding material and preparation method thereof

A technology of carbon nanotubes and high electrical performance, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve problems such as high electric field strength, insulation layer breakdown, and electric field deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

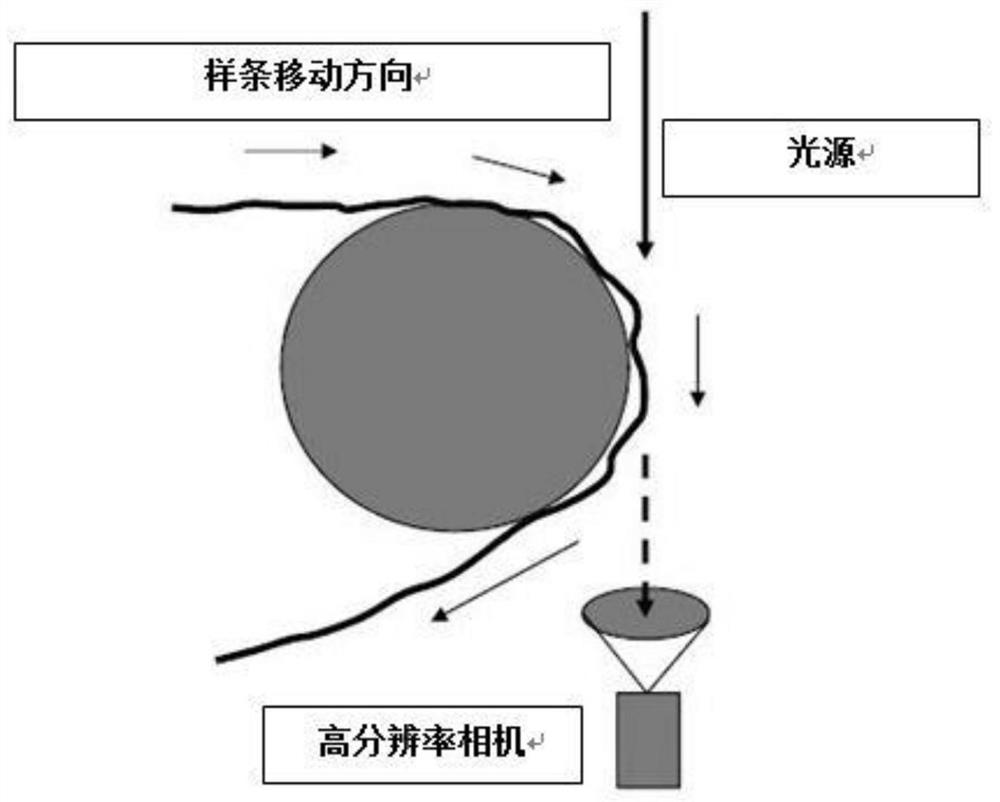

Method used

Image

Examples

Embodiment 1

[0044]

[0045]

[0046] Accurately weigh various materials according to the formula for use, and passivate white oil, graphene microflake powder, single-walled carbon nanotubes, conductive carbon black, dispersant, dispersant, antioxidant, anti-scorch agent, and metal ions The agent and lubricant are fully mixed in a high-speed mixer, the mixing time is 10±2min, the temperature is controlled at 50±5°C, and the stirring rate is 40±3RPM, so that each raw material component is mixed in a high-speed mixer. Add ethylene-ethyl acrylate copolymer, ethylene octene copolymerized thermoplastic elastomer, and linear low-density polyethylene into the main feed of the reciprocating single-screw mixing extruder through a weight loss scale, and add the high-mixed powder through a weight loss scale The side feeding of the reciprocating single-screw mixing extruder, the white oil is injected into the mixing section of the reciprocating single-screw mixing extruder through the injection g...

Embodiment 2

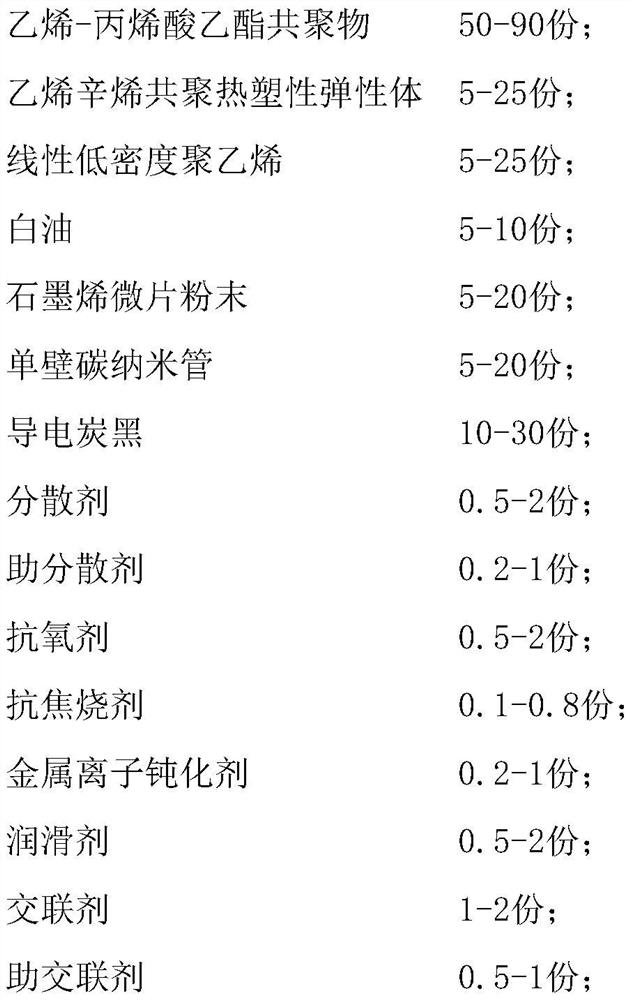

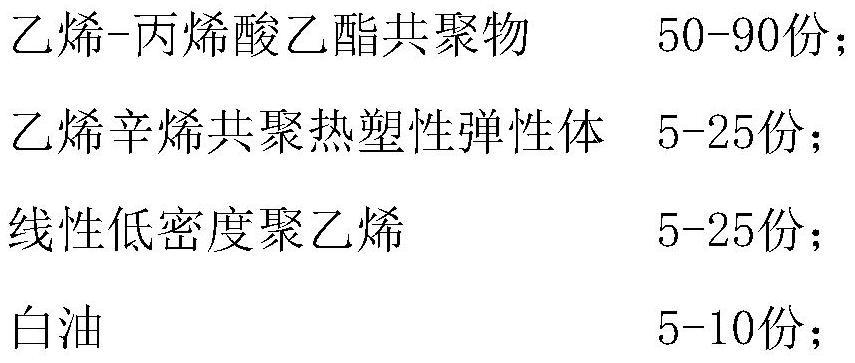

[0049] A raw material of graphene and carbon nanotube synergistic high-electric performance semi-conductive shielding material includes the following components in parts by weight:

[0050]

[0051]

[0052] Processes such as mixing and extrusion granulation are the same as in Example 1. The properties of the prepared cable materials are shown in Table 1.

Embodiment 3

[0054] The raw material of a graphene and carbon nanotube synergistic high electrical performance semi-conductive shielding material includes the following components in parts by weight

[0055]

[0056]

[0057] Processes such as mixing and extrusion granulation are the same as in Example 1. The properties of the prepared cable materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com