Air vent manufactured in mode of forming branch air passages on side wall of main air passage

A technology of main air passage and vent hole is applied in the field of improvement of the structure of the fire hole of the gas burner, and can solve the problems of increased flow resistance of the fire hole and small heat flow of the fire hole, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

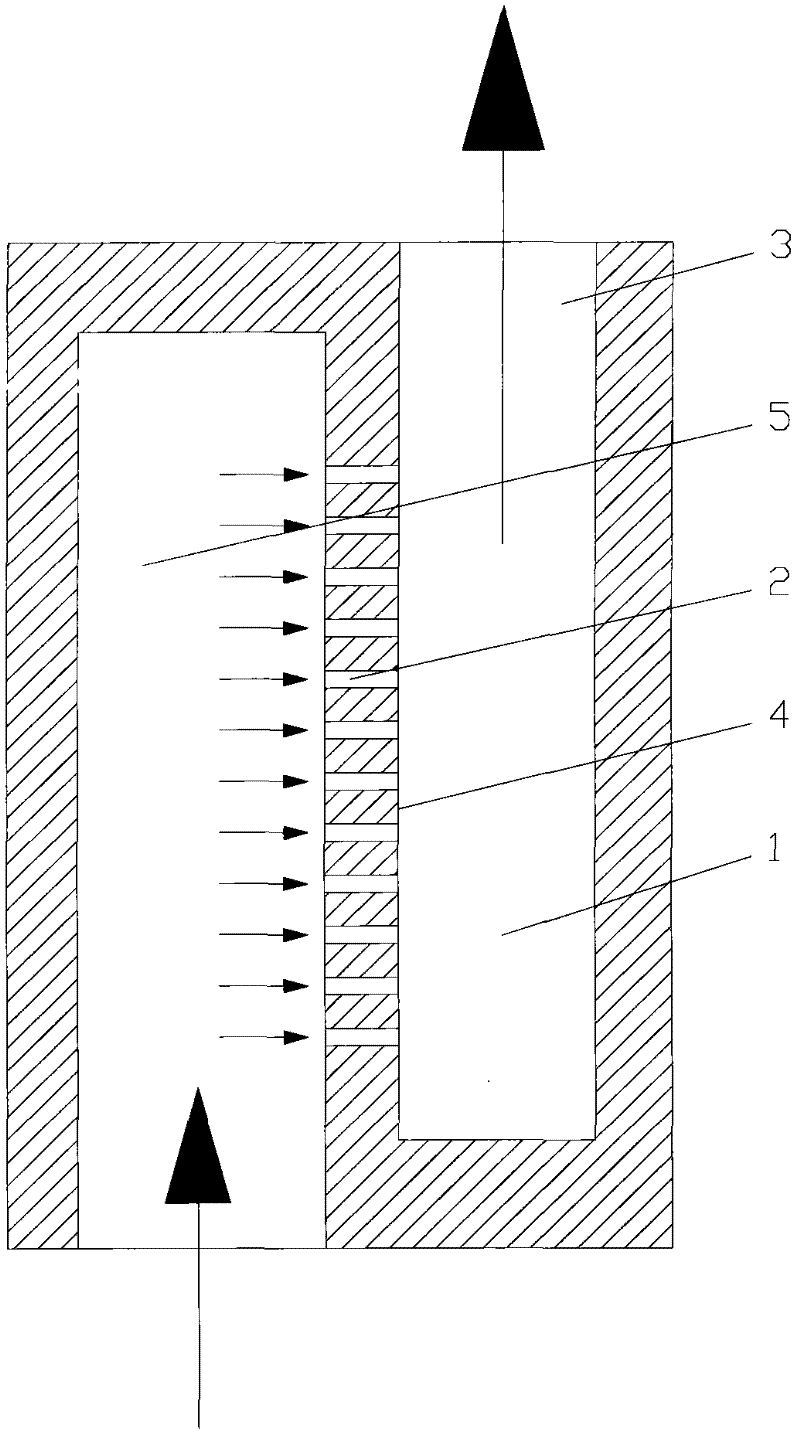

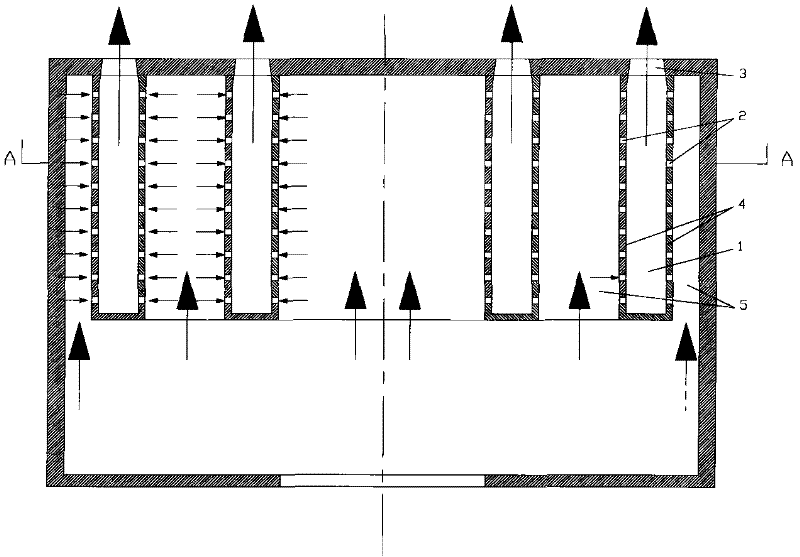

[0020] Embodiment 1: as figure 2 , image 3 , Figure 4 shown

Embodiment 2

[0021] Embodiment 2: as Figure 5 , Figure 6 , Figure 7 shown

Embodiment 3

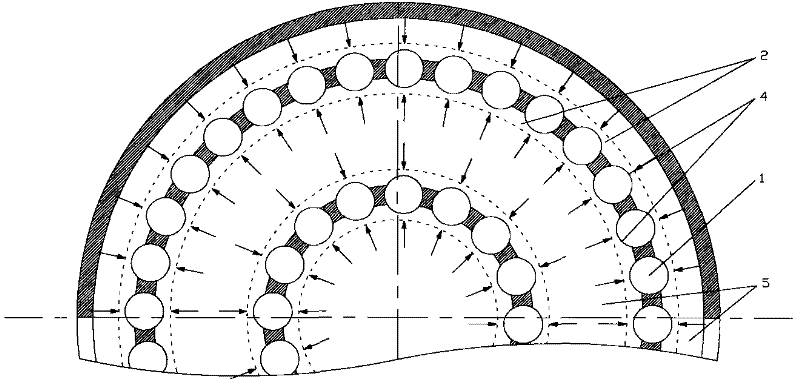

[0022] Embodiment 3: as Figure 8 , Figure 9 , Figure 10 shown

[0023] Several branch air passages 2 are opened on the side wall 4 of the main air passage 1, and the main air passage 1 communicates with the mixed gas chamber 5 by using several branch air passages 2 to form the entrance 2 with several branch air passages 2 and the main air passage Channel 1 is a transmission channel, and the upper opening of main air channel 1 is the vent hole of outlet 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com