Efficient heat exchange fin

A high-efficiency technology for heat exchange fins, applied to heat sinks, fluid heaters, heat exchange equipment, etc., can solve the problem of uneven distribution of flue gas in fins, improve heat exchange effect, improve heat exchange efficiency, and extend contact the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

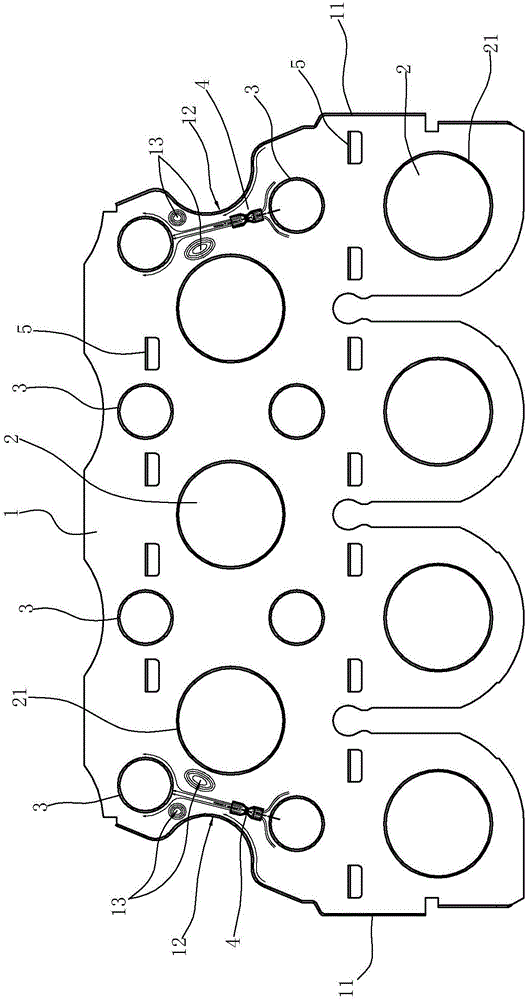

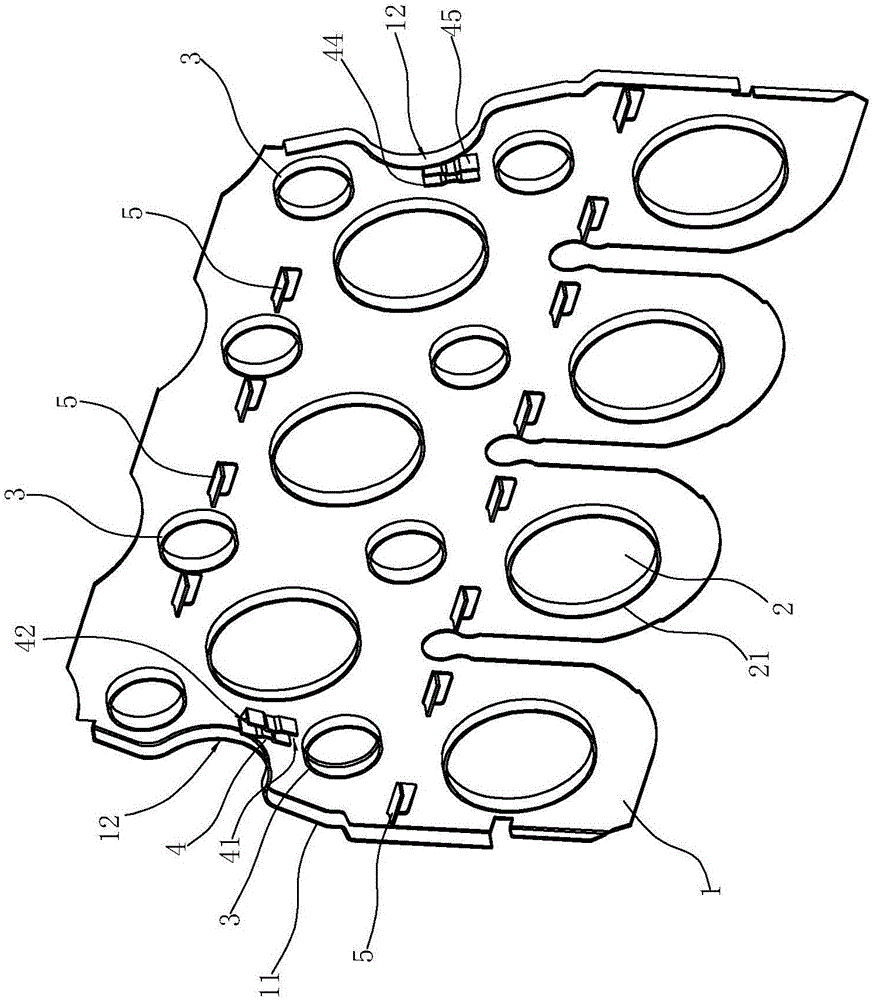

[0021] Such as Figure 1 to Figure 4 As shown, the high-efficiency heat exchange fins include:

[0022] The base plate 1 is provided with heat exchange tube holes 2 , spoiler rings 3 , guide channels 4 and baffles 5 at intervals on the surface of the base plate 1 .

[0023] in,

[0024] Both sides of the substrate 1 have outwardly protruding flanges 11 , and the flanges located between the upper and lower rows of spoiler coils 3 are recessed inward to form energy-gathering arcs 12 .

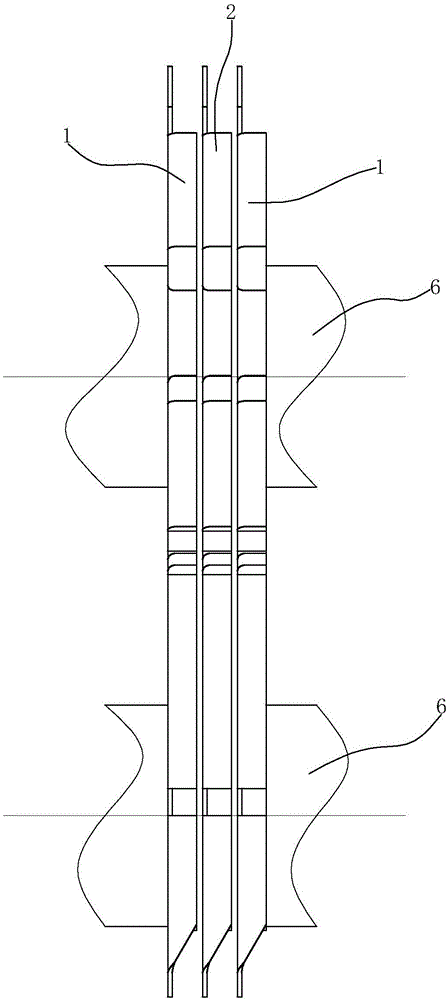

[0025] There are multiple heat exchange tube holes 2, which are used to pass through the heat exchange tubes 6. These heat exchange tube holes 2 are arranged alternately in upper and lower rows. There are four heat exchange tube holes 2 in the lower row. There are three heat exchange tube holes 2; protruding flanges 21 are provided along the periphery of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com