Cooling device for cooling components of the power electronics, said device comprising a micro heat exchanger

a technology of power electronics and cooling components, which is applied in the direction of domestic cooling apparatus, lighting and heating apparatus, basic electric elements, etc., can solve the problems of inferior efficiency of electronic components, significant rise in component temperature, and inability to meet the needs of cooling components, etc., to achieve large heat flow, solve problems, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

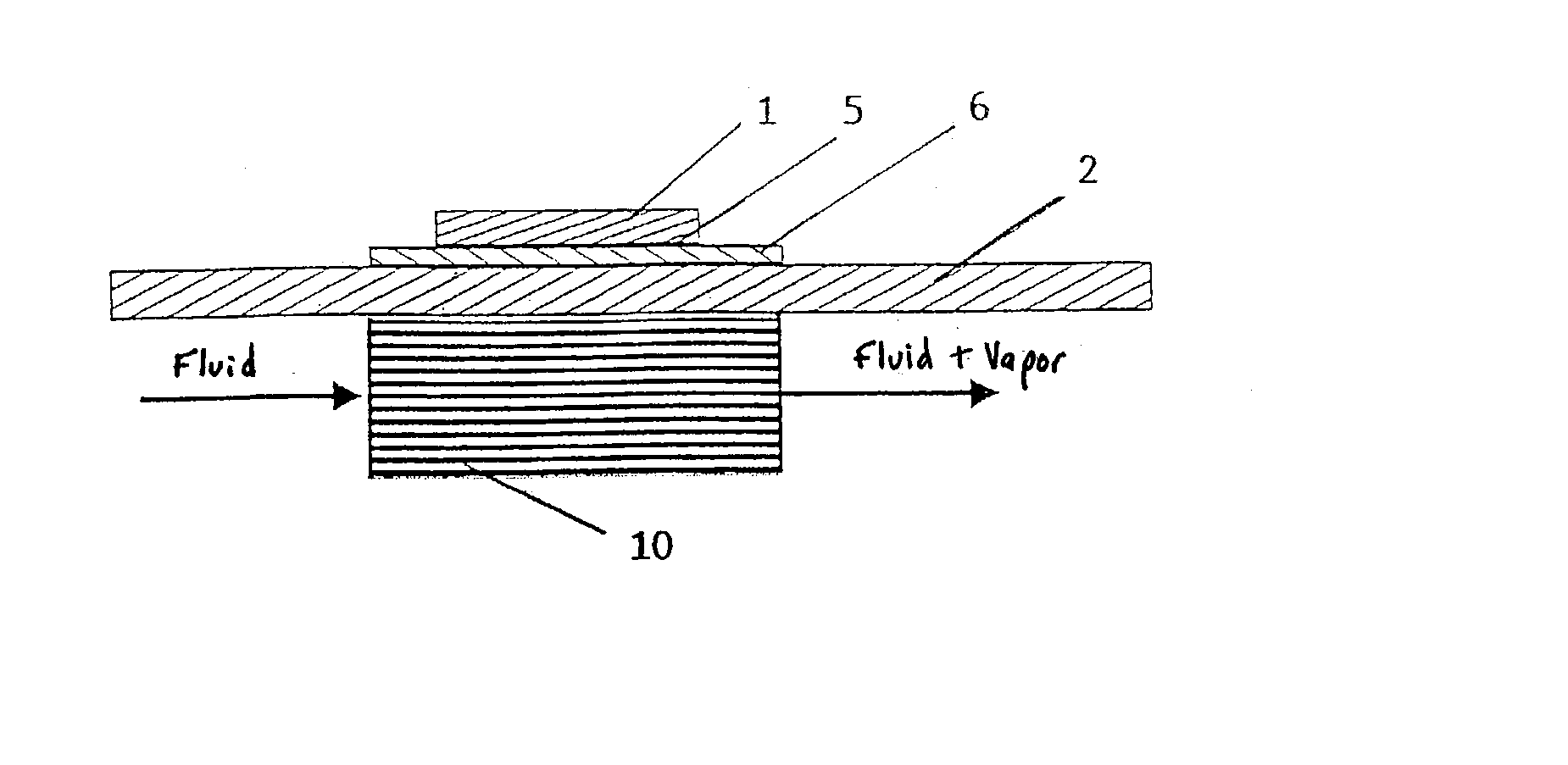

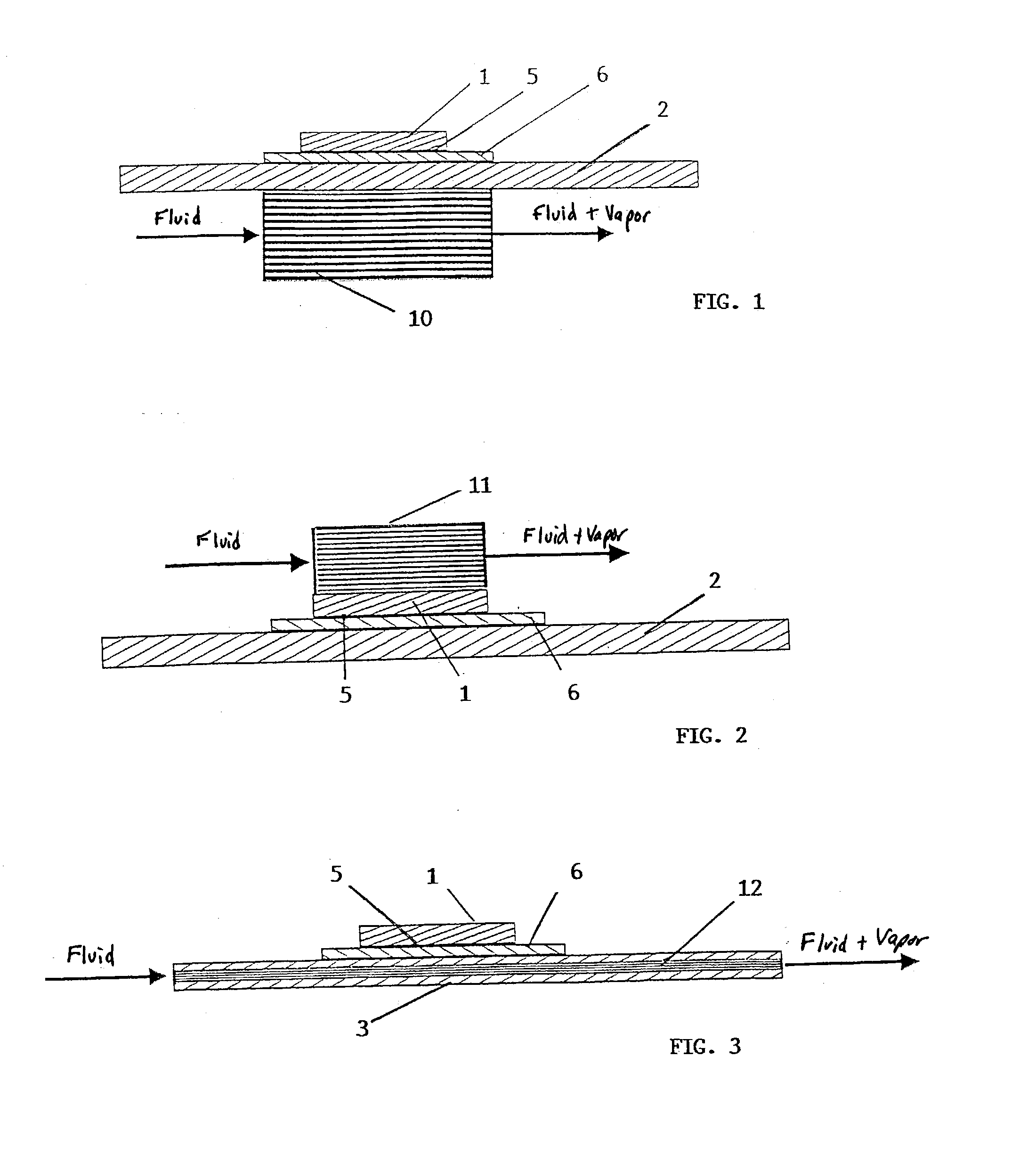

[0018] Three variants of a cooling device according to the present invention for cooling of components of power electronics are illustrated in FIGS. 1 through 3.

[0019] In a first exemplary embodiment, shown in FIG. 1, a micro heat exchanger 10 is situated on the back of an insulating circuit board substrate 2 opposite a component 1 to be cooled, the component being connected to circuit board substrate 2 on the front of substrate 2 via an electrical and thermal contact 6 and a solder layer 5. A heat flow is released in power electronics component 1, the heat flow being transferred to micro heat exchanger 10 via solder 5, electrical and thermal contact 6, and circuit board substrate 2 (board for short).

[0020] Fluid coolant which is slightly undercooled is fed to micro heat exchanger 10. Initially the coolant heats up to boiling and then starts boiling in the channels of micro heat exchanger 10. This is also called flow boiling of a saturated fluid.

[0021] Flow boiling of an undercooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com