Ellipsoidal corrugated heat transmission sheet structure for air/gas preheater

A gas preheater, plate structure technology, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of poor heat transfer effect, high waste heat temperature, large flue gas volume, etc. Flow resistance, high strength and stiffness, effect of reducing runner resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

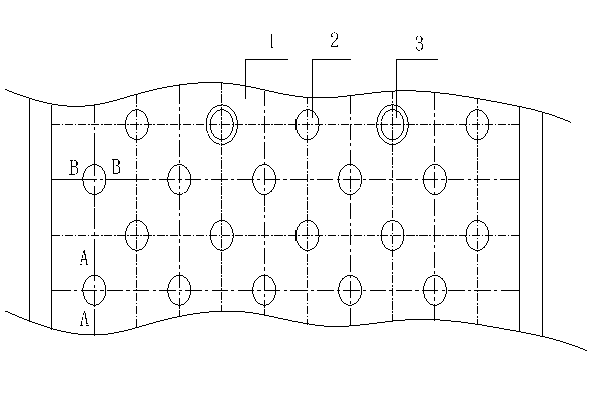

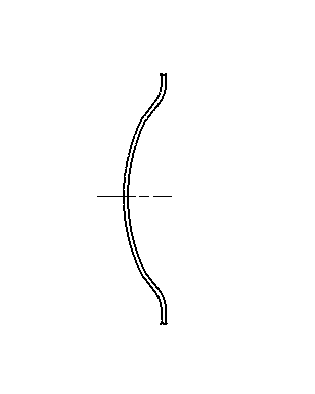

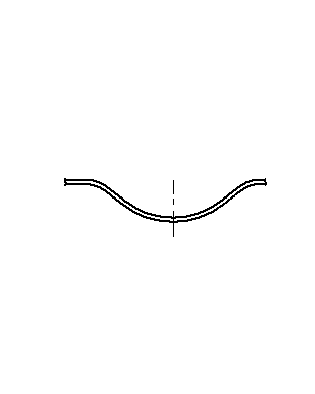

[0014] Figure 1 ~ Figure 3 It is a structural schematic diagram of the corrugated heat transfer plate of the present invention. In the figure, an ellipsoidal corrugated heat transfer plate structure is used for an air / gas preheater. The corrugations in the corrugated area of the heat transfer plate 1 are composed of semi-ellipsoidal surfaces 2 arranged in a matrix, and the semi-ellipsoidal The major axis of the curved surface is in the same direction as the long side of the heat transfer sheet, and the central axis of the semi-ellipsoidal surface is in the same direction as the broad side of the heat transfer sheet. The matrix arrangement can be a convex semi-ellipsoidal surface on the even-numbered columns of the odd-numbered rows, a concave semi-ellipsoidal surface on the odd-numbered columns of the even-numbered rows, or it can be on the even-numbered co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com