Heat exchange tube with inner fins and heat exchanger

A technology of heat exchange tubes and inner fins, which is applied in the field of heat exchange equipment, can solve the problems that the performance of coolers cannot be effectively exerted, the impact of heat exchange performance, and high manufacturing costs, and achieve compact structure, improved reliability, and low manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

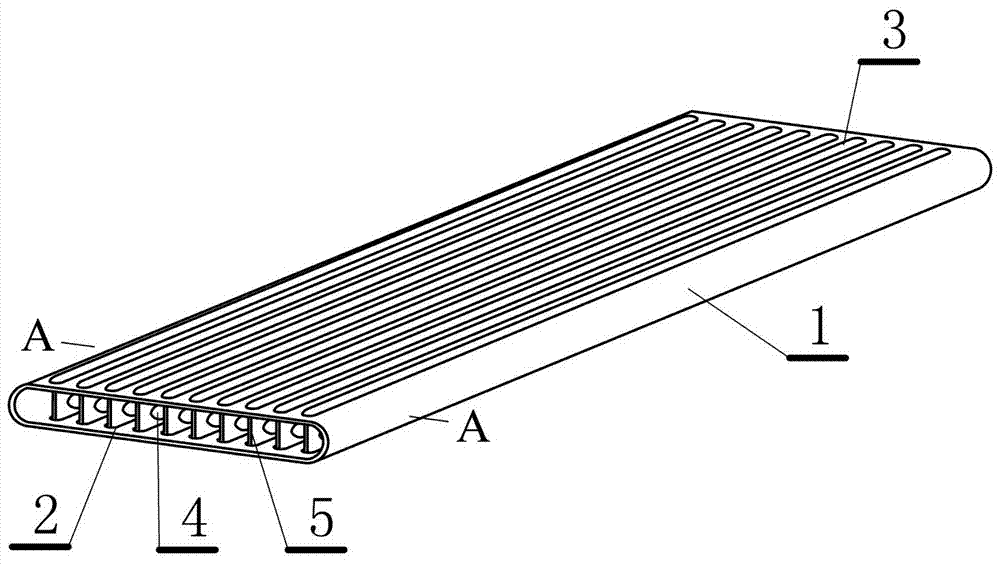

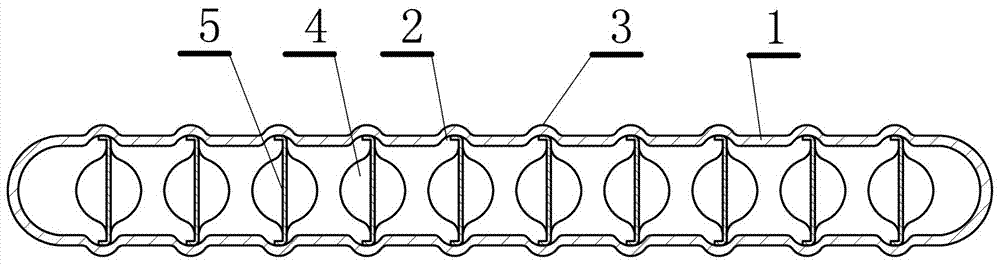

[0041] This embodiment is a heat exchange tube with inner fins, such as figure 1 shown. This embodiment includes: a tube body 1 with a long rectangular cross-section, the upper and lower sides of the tube body are correspondingly provided with a plurality of paired strip-shaped depressions 2 along the fluid movement direction in the tube, and the plurality of strips Shaped depressions form elongated protrusions 3 on the outer surface of the tube; at least one fin 5 with point protrusions or short-line protrusions 4 is connected to the upper and lower corresponding elongated depressions, see figure 2 .

[0042] The shape of the tube body described in this embodiment is similar to a traditional flat tube, and its cross-sectional shape is a rectangle with longer sides, or simply a flat tube with an elongated cross section, such as figure 2 As shown, the two short sides of the rectangle can be straight sides or semi-circular transitions (such as figure 2 The cross-sectional ...

Embodiment 2

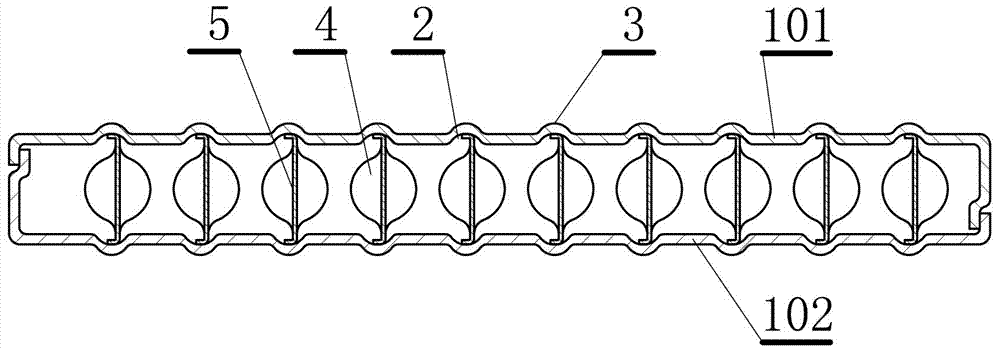

[0059] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the pipe body. The pipe body described in this embodiment is composed of upper and lower parts 101, 102, as image 3 mentioned.

[0060] In order to facilitate the processing of the pipe body, the present embodiment divides the pipe body into upper and lower parts, and after bending, the bending part is connected to form a whole. That is to say, the pipe body is formed by bending and welding two plates, and has two connection welds. The pipe body designed in this way has very good process performance. The strip-shaped protrusions on the surface of the tube body can be very convenient for punching and forming, and at the same time, it is also convenient for the fins to be conveniently welded in the tube body. The interface of the upper and lower parts of the pipe body can be symmetrically designed on both sides of the pipe body, or as image 3 The tubes in the mi...

Embodiment 3

[0062] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the pipe body. The outer surface of the tube described in this embodiment is provided with a supporting protrusion 103, such as Figure 4 shown.

[0063] When the heat exchange tube is fed with high-temperature gas during work, the tube itself will expand thermally, which will reduce the distance between the heat exchange tubes, which is very harmful. The smaller the distance between the heat exchange tubes, the narrower the circulation channel of the coolant, which affects the efficiency of the coolant to remove heat. In order to keep the distance between the heat exchange tubes constant, this embodiment sets point-shaped or short-line protrusions outside the tube body, and the protrusions between two adjacent heat exchange tubes interact to effectively place the tube body Close to each other and maintain a distance between each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com