Soya-bean milk making device

A technology for a soymilk machine and a container, which is applied in the field of soymilk machine, can solve the problems of no application of cooking utensils and complicated structure, and achieve the effects of simple and reasonable structure, large heating area and good heat preservation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

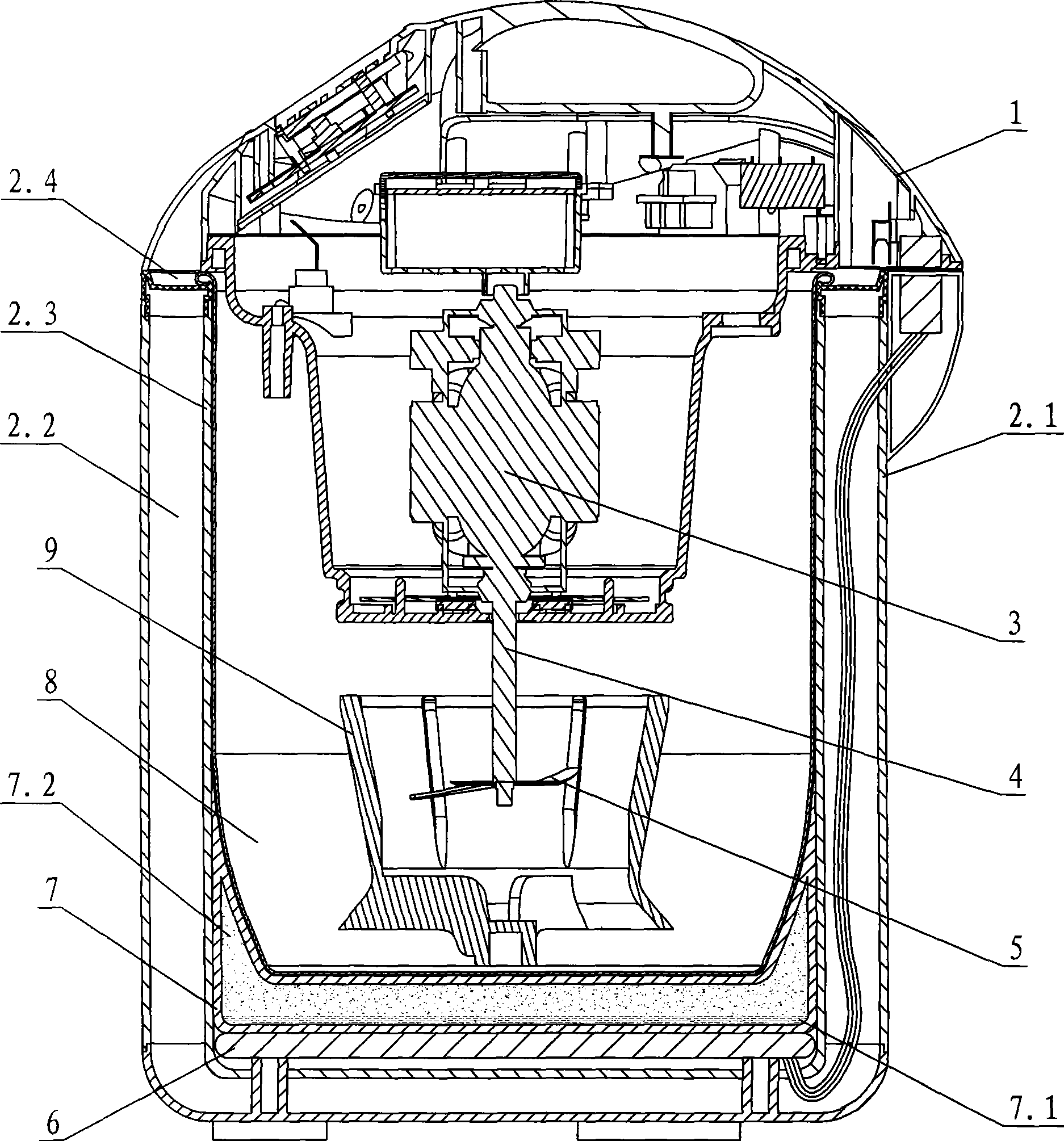

[0014] see figure 1 , The soybean milk machine includes a container 8 and a heating plate 6, and an outer barrel is arranged outside the container, which is separately arranged from the container. The outer barrel has a double-layer structure, the outer layer is the outer shell 2.1, the inner layer is the reflective layer 2.3, a heat insulation cavity 2.2 is formed between the outer shell and the reflective layer, the top surface is provided with a drainage groove 2.4, and the outer wall is provided with a water collection box ( Not shown in the figure) communicates with drain tank.

[0015] The heating plate 6 is arranged on the inner bottom of the reflective layer 2.3, and a groove-shaped superconductor is connected to the heating surface, so as to heat the container 8 through the superconductor. The superheater includes a groove-shaped casing 7, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com