Sludge treatment method and sludge foaming lightweight concrete produced therefrom and use

A lightweight concrete and sludge treatment technology, applied in the field of lightweight foamed concrete, can solve the problems of dehydration, drying, incineration, other costs and waste of landfill, air pollution by incineration sludge, and no sludge recycling. , to achieve the effect of good absorption and dispersion, low absorption rate and low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

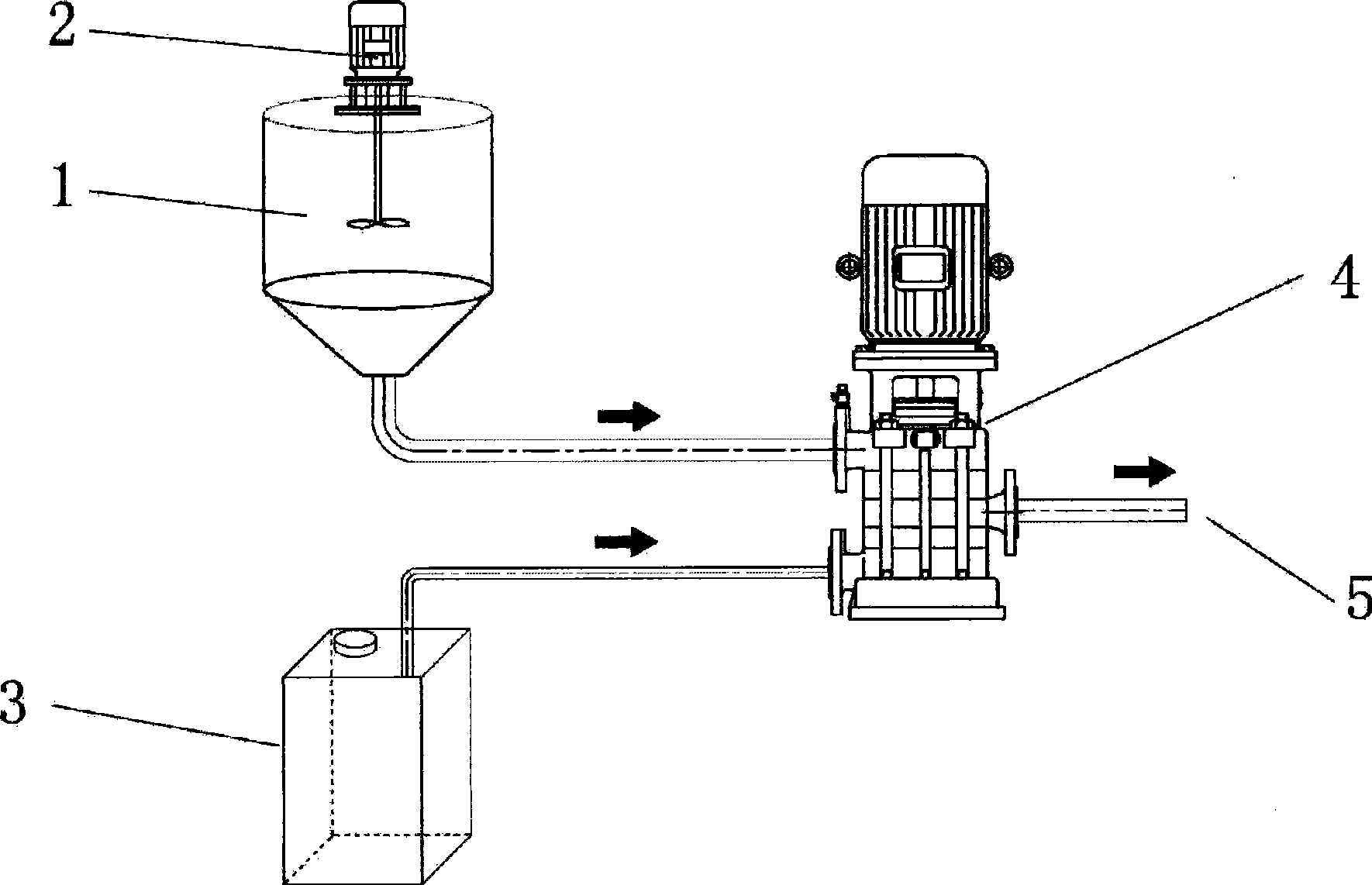

Image

Examples

Embodiment 1

[0036] Add 1,000 grams of quicklime to 1,000 grams of sludge, and stir well to make the quicklime and the water in the sludge react chemically to form sludge slaked lime; then add 800 grams of cement, 400 grams of fly ash, and 800 grams of water to the sludge slaked lime , fully stirred to form sludge concrete; through the foaming system of the foaming machine, 120 grams of foaming agent is fully foamed by mechanical means, and the foam is evenly mixed with the sludge concrete to obtain sludge foamed lightweight concrete.

Embodiment 2

[0038] Add 750 grams of quicklime to 1000 grams of sludge, and stir well to make the quicklime and the water in the sludge react chemically to form sludge slaked lime; then add 875 grams of cement, 650 grams of fly ash and 1100 grams of water to the sludge slaked lime , fully stirred to form sludge concrete; through the foaming system of the foaming machine, 87.5 grams of foaming agent was fully foamed by mechanical means, and the foam was evenly mixed with the sludge concrete to obtain sludge foamed lightweight concrete.

Embodiment 3

[0040] Add 500 grams of quicklime to 1000 grams of sludge, and stir well to make the quicklime and the water in the sludge react chemically to form sludge slaked lime; then add 1070 grams of cement, 645 grams of fly ash and 1070 grams of water to the sludge slaked lime , fully stirred to form sludge concrete; through the foaming system of the foaming machine, 215 grams of foaming agent is fully foamed by mechanical means, and the foam is evenly mixed with the sludge concrete to obtain sludge foamed lightweight concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com