Pressure-sensitive optical cable with armor layer

An armored layer and pressure-sensitive technology, which is applied in the field of optical cables for pressure sensing, can solve problems such as inability to adapt to environmental conditions, poor lateral pressure resistance and tensile resistance, and achieve convenient use, improve lateral pressure resistance, and prevent erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

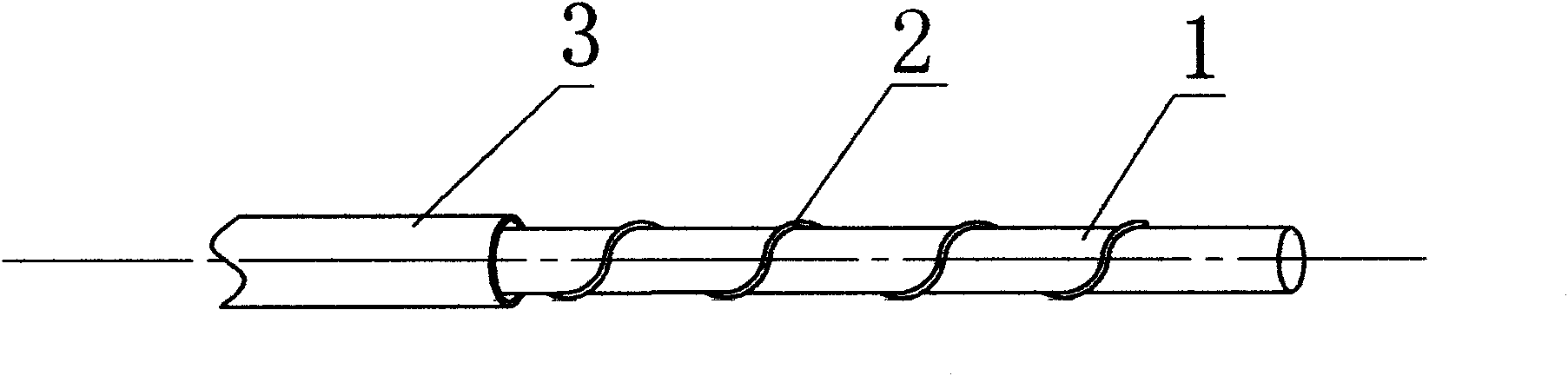

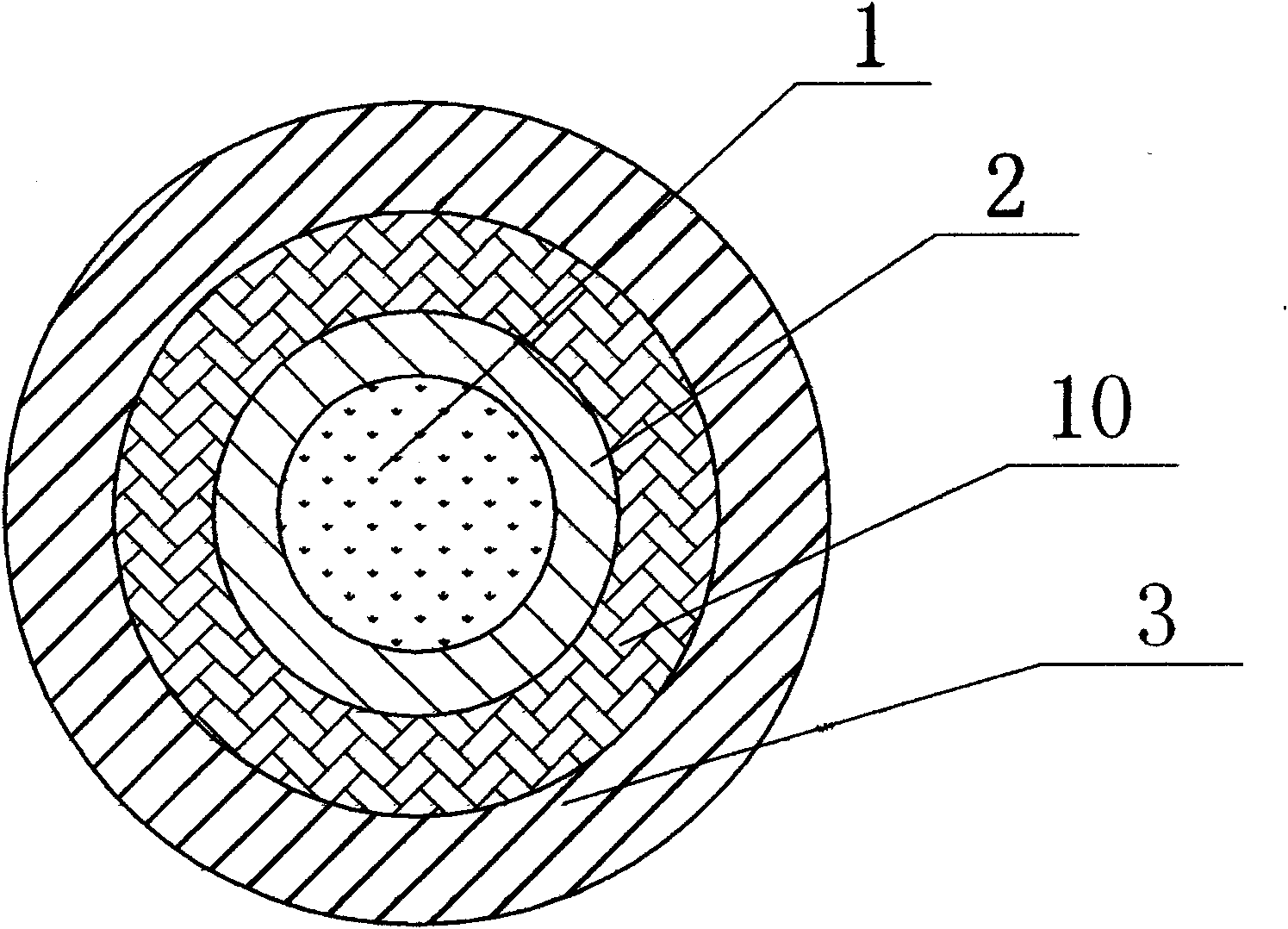

[0031] Such as figure 2 As shown, the present invention includes a signal optical fiber 1 and a fiber filament 2 helically wound on the signal optical fiber, and an armor layer 10 and an outer sheath 3 are arranged on the periphery in turn. During actual manufacturing, the voids inside the outer sheath 3 are filled with water-blocking materials.

[0032] In this embodiment, the outer sheath 3 is deformed under external pressure, thereby transmitting the external force to the fiber filament 2 helically wound on the signal optical fiber, and under the action of pressure, the fiber filament 2 causes the signal optical fiber 1 to bend and deform , thereby changing the bending loss of the signal optical fiber 1 , thereby realizing the modulation of the transmission light intensity in the signal optical fiber 1 . In this way, the pressure signal is converted into an optical signal and transmitted through the signal optical fiber 1 to realize remote measurement or distributed measu...

Embodiment 2

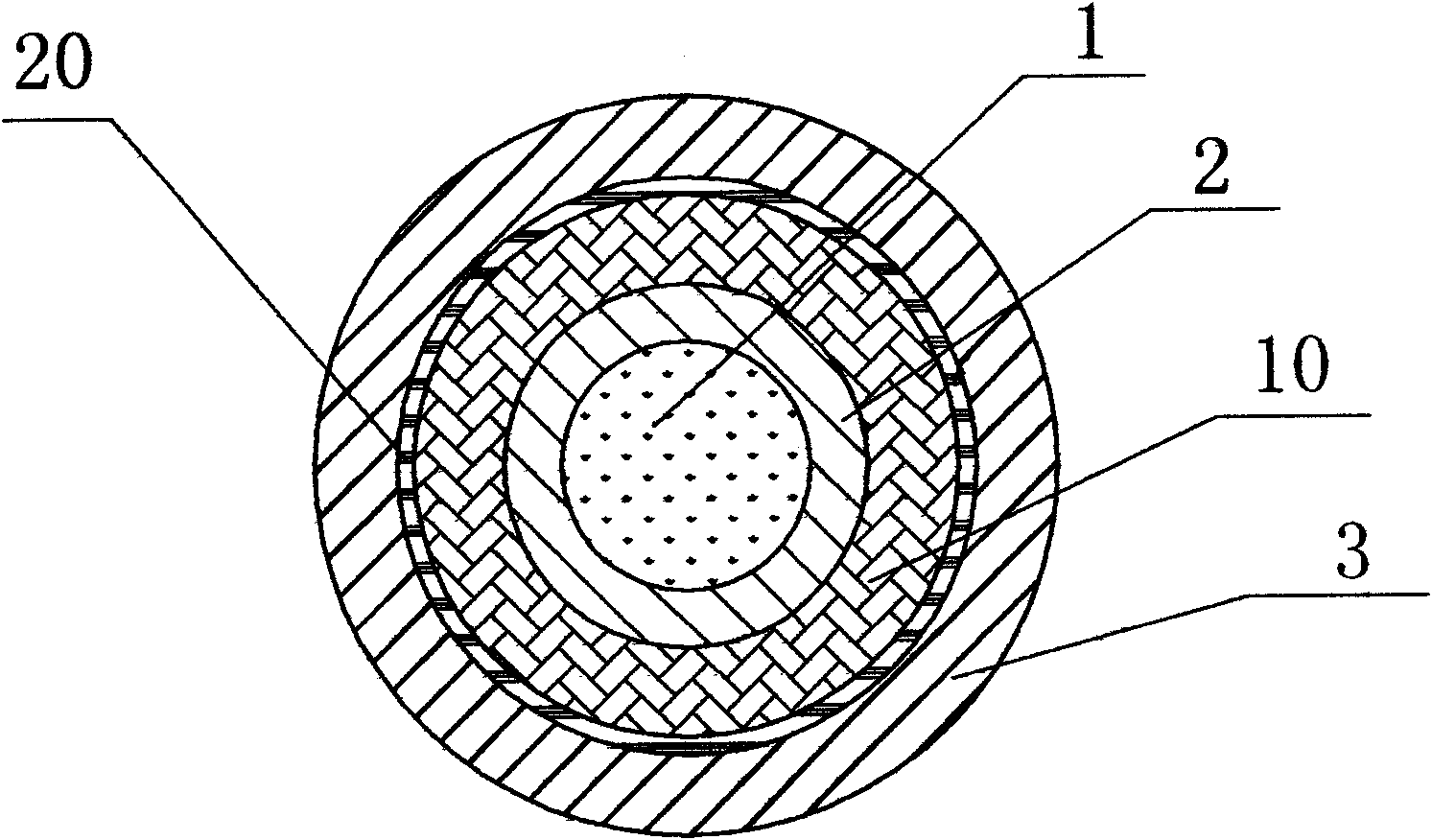

[0035] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is that there is a film material layer between the outer sheath 3 and the armor layer 10, which can prevent the pressure-sensitive optical cable from maintaining the pressure-sensitive optical cable during processing and use. Roundness. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0037] Such as Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that there are two tensile elements inside the outer sheath 3 near the armor layer 10, which can be steel wires or FRP rods, to strengthen the compression force. Tensile properties of sensitive optical cables. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com