Microorganism for controlling harm of oil field sulfate reductive bacterium and application thereof

A microbial preparation, sulfate technology, applied in biological water/sewage treatment, bacteria, water/sludge/sewage treatment, etc., can solve the problems of corrosive sulfide, environmental pollution, high cost, and reduce anti-corrosion costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Firstly, the denitrifying bacteria culture is prepared by conventional aerobic fermentation technology according to the ratio, and then the nutrient elements, synergistic nutrient elements and the denitrifying bacteria culture are uniformly mixed. Alternatively, when in use, denitrifying bacteria culture, nutrient elements, and synergistic nutrient elements may be added separately.

[0029] The composition of the microbial preparation and its content in the treated water are as follows:

[0030] 1) Denitrifying bacteria culture composition: Pseudomonas putida 5×10 7 Bacteria / mL, water balance; denitrifying bacteria culture addition is 1%wt of the treated water;

Embodiment 2

[0034] The difference from Example 1 is that the composition of the microbial preparation and the content in the treated water are as follows:

[0035] 1) Denitrifying bacteria culture composition: Pseudomonas putida 2×10 8 bacteria / mL, water balance; denitrifying bacteria culture addition is 0.5%wt;

[0036] 2) Sodium nitrite: 10mg / L;

[0037] 3) Sodium tungstate: 10ppm.

Embodiment 3

[0039] The difference from Example 1 is that the composition of the microbial preparation and the content in the treated water are as follows:

[0040] 1) Composition of denitrifying bacteria culture: Thiobacillus denitrificans 2×10 8 bacteria / mL, water balance; denitrifying bacteria culture addition is 0.01%wt;

[0041] 2) Sodium nitrite and sodium phosphate: 50mg / L each;

[0042] 3) Sodium tungstate: 100ppm.

[0043] Microbial preparations are continuously or intermittently added to the surface water treatment system or / and reinjection water system, the dosage rate of continuous dosage is 10-500L / min; the dosage speed of intermittent dosage is 10-1000L / min, Dosing for 1-12 hours per day, resting for 23-12 hours (the process parameters of microbial preparations should be determined according to the relevant parameters such as the water injection speed and quantity on the oil well site)

[0044] Method 1: Dynamic dosing of surface system

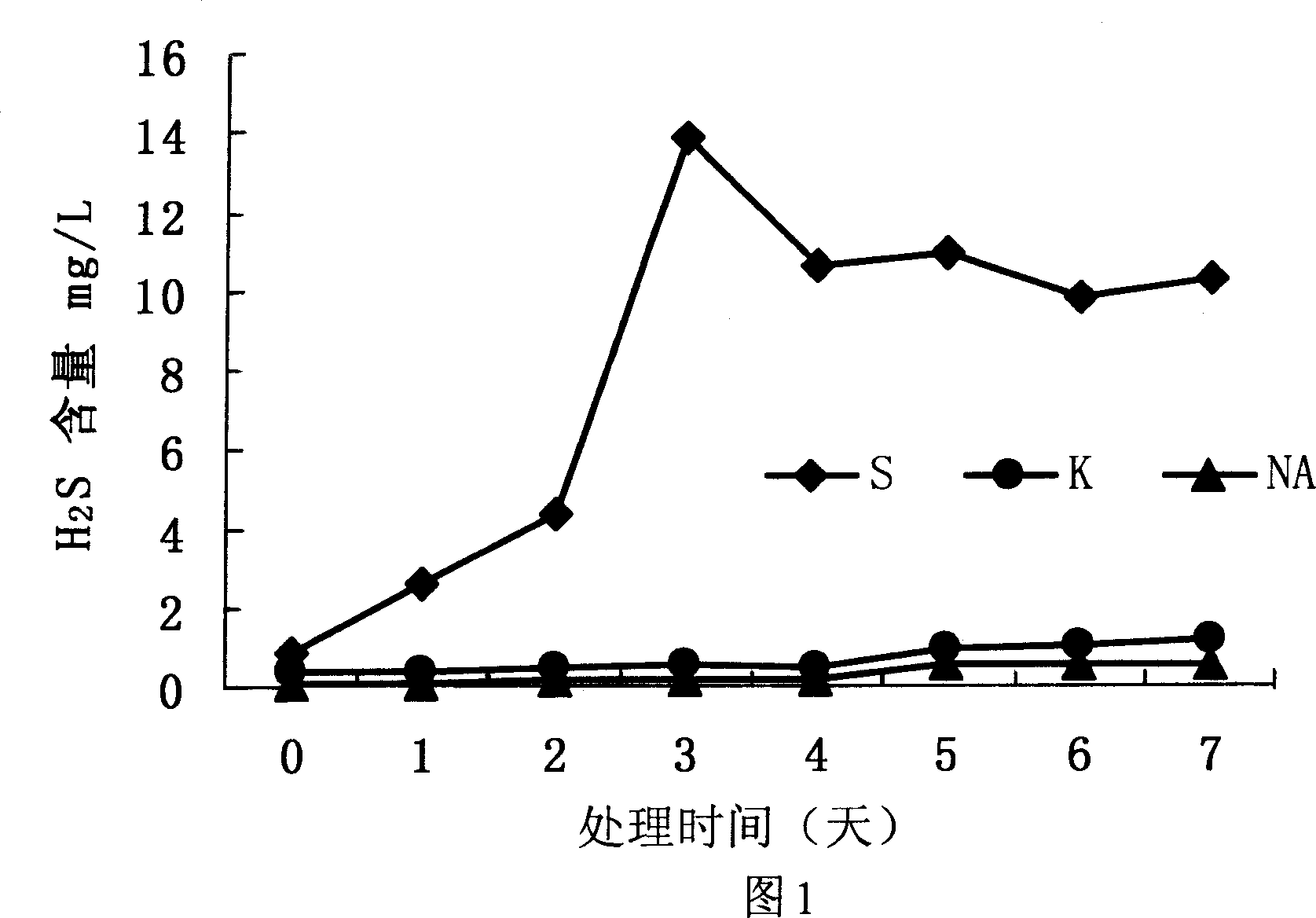

[0045] Taking Example 1 as an exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com