Metallographic corrosion method of 6082 aluminum alloy

A metallographic corrosion and aluminum alloy technology, applied in the direction of instruments, analysis materials, measuring devices, etc., can solve the problems of fuzzy structure, high cost, difficult to corrode, etc., and achieve the effect of clear metallographic structure, reduced corrosion cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

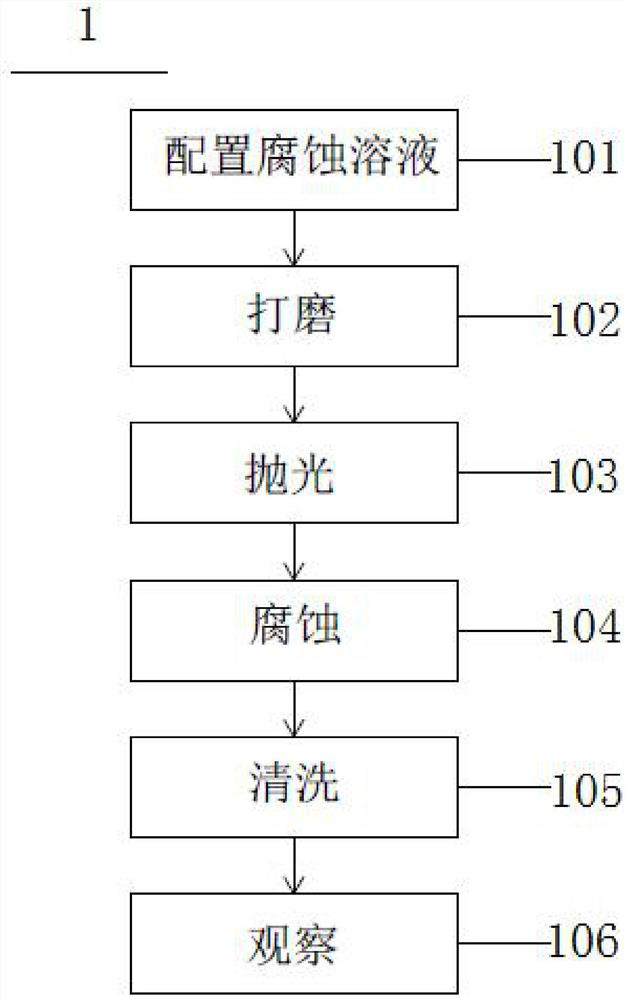

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic flow chart of steps of metallographic corrosion method 1 of 6082 aluminum alloy according to an embodiment of the present invention. 6082 aluminum alloy metallographic corrosion method 1 includes the following steps 101-106, wherein:

[0034] Step 101, configuring an etching solution. Mix sodium ethoxide, sodium fluoride and distilled water to prepare a corrosion solution.

[0035] Specifically, a container is prepared, sodium ethylate, sodium fluoride and distilled water are poured into the container and mixed to prepare a corrosion solution. Preferably, the mass fraction of sodium ethoxide in the configured etching solution is 3%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com