High-temperature high-pressure multifunctional horizontal well damage appraisement instrument

A high-temperature, high-pressure, multi-functional technology, applied in scientific instruments, wellbore/well parts, suspension and porous material analysis, etc., can solve the problems of clogging and consumption of circulating pipelines, and achieve the elimination of clogging of working fluid circulating pipelines and improve the use of Effects of lifespan and dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

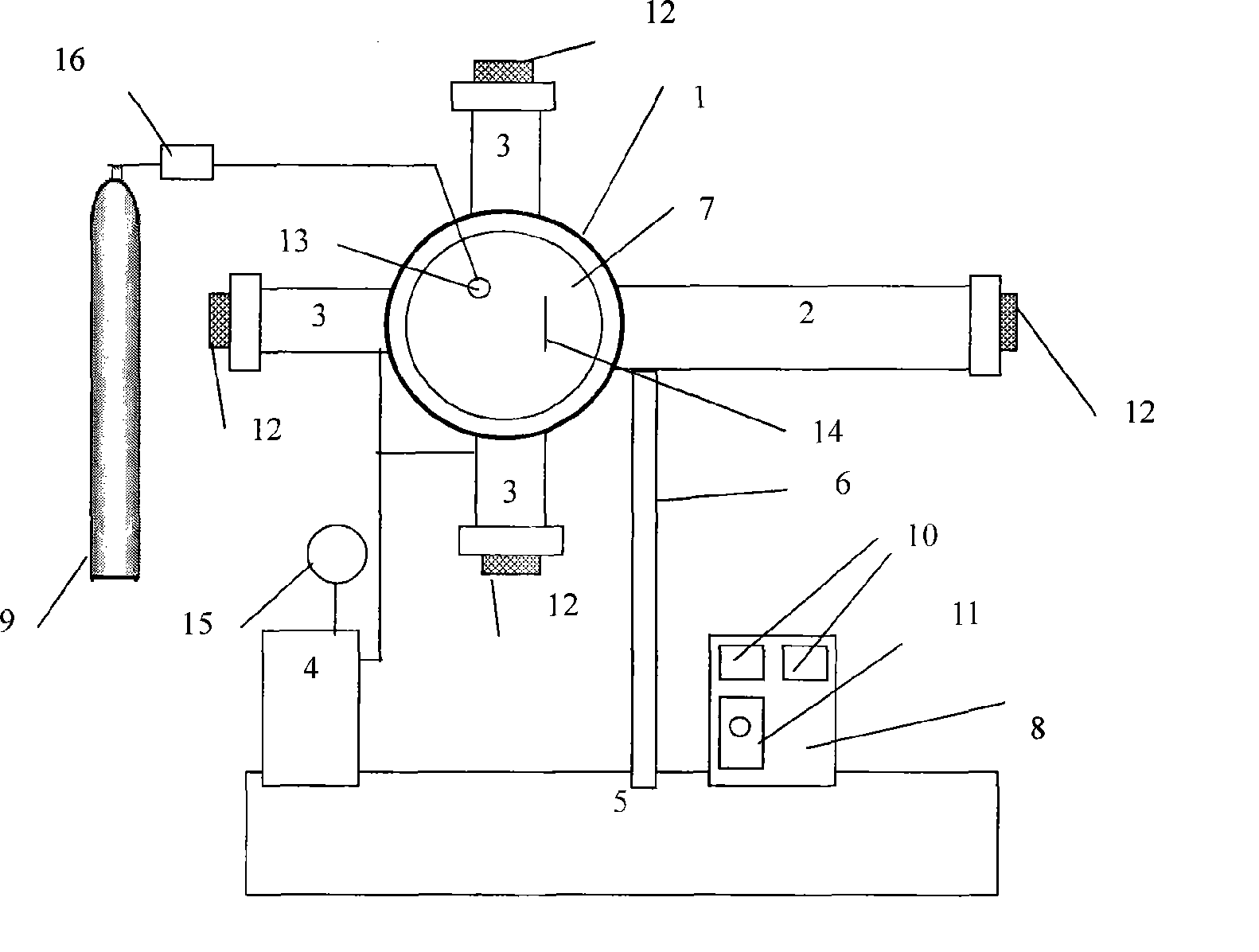

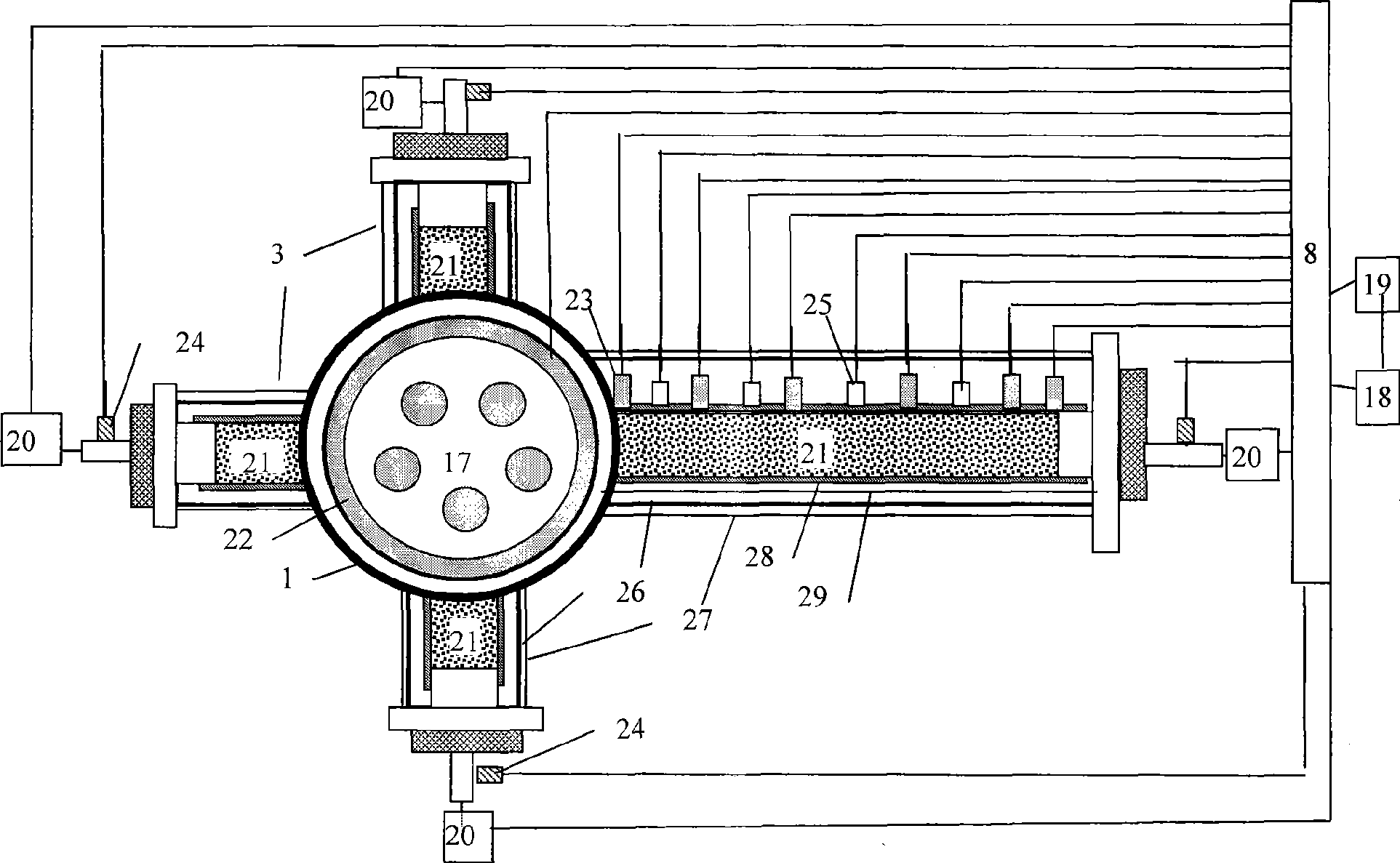

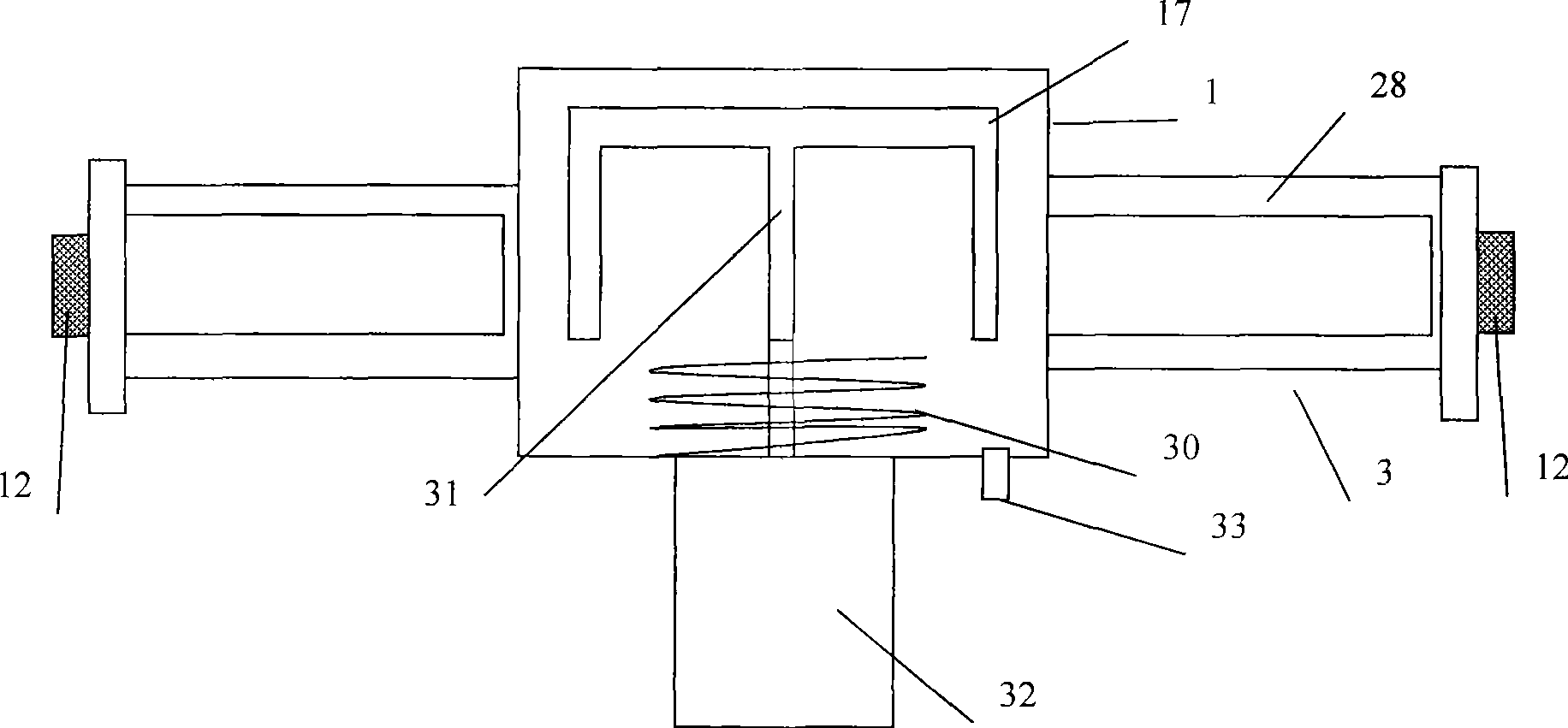

[0022] Further illustrate the present invention according to accompanying drawing below.

[0023] see figure 1 , high temperature and high pressure multifunctional horizontal well damage evaluation instrument, mainly composed of working fluid circulation kettle body 1, one long core holder 2, three short core holders 3, confining pressure pump 4, acquisition control box 8, bracket 6 , the confining pressure pump 4 and the acquisition control box 8 are fixed on the support base 5, and the long core holder 2 and the short core holder 3 are connected together through the working fluid circulation kettle body 1 and supported by the support 6. The gland 7 on the top of the working fluid circulation kettle body 1 has a pressure hole 13 and a gland handle 14, and the pressure hole is connected with the nitrogen cylinder 9. A temperature controller 10, a cycle motor controller 11 and a data acquisition card are installed in the acquisition control box 8. The confining pressure pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com